SETUP FOR SPRAYING

CONNECTING GUN TO MATERIAL HOSE

Gun should be connected by a suitable length of 3/8"

diameter material hose fitted with a connector with a

3/8" NPS(f) nut at gun end. 1/4" diameter hose is

recommended for use with low viscosity materials.

(Fluid hoses of different composition are available for

special fluids.)

CONNECTING GUN TO ATOMIZING AIR

Gun should be connected by a suitable length of 5/16"

or 3/8" diameter air hose fitted with a connector and a

1/4" NPS(f) nut at gun end.

CONNECTING GUN TO CYLINDER AIR

Gun should be connected by a suitable length of 3/16"

I.D. or 1/8" I.D. air hose of shortest length possible

with 1/4" NPS(f) connector.

OPERATING THE MACH 1AR HVLP AUTOMATIC SPRAY GUN

CONTROLLING THE MATERIAL FLOW

When fed from a pressure supply, an increase in the

material pressure will increase the rate of flow. Correct

fluid nozzle size ensures correct material flow rate. If

necessary, fluid flow can also be adjusted by adjusting

the amount of needle travel. This is done by adjusting

the ratchet housing cap (35) until the correct needle

travel is achieved.

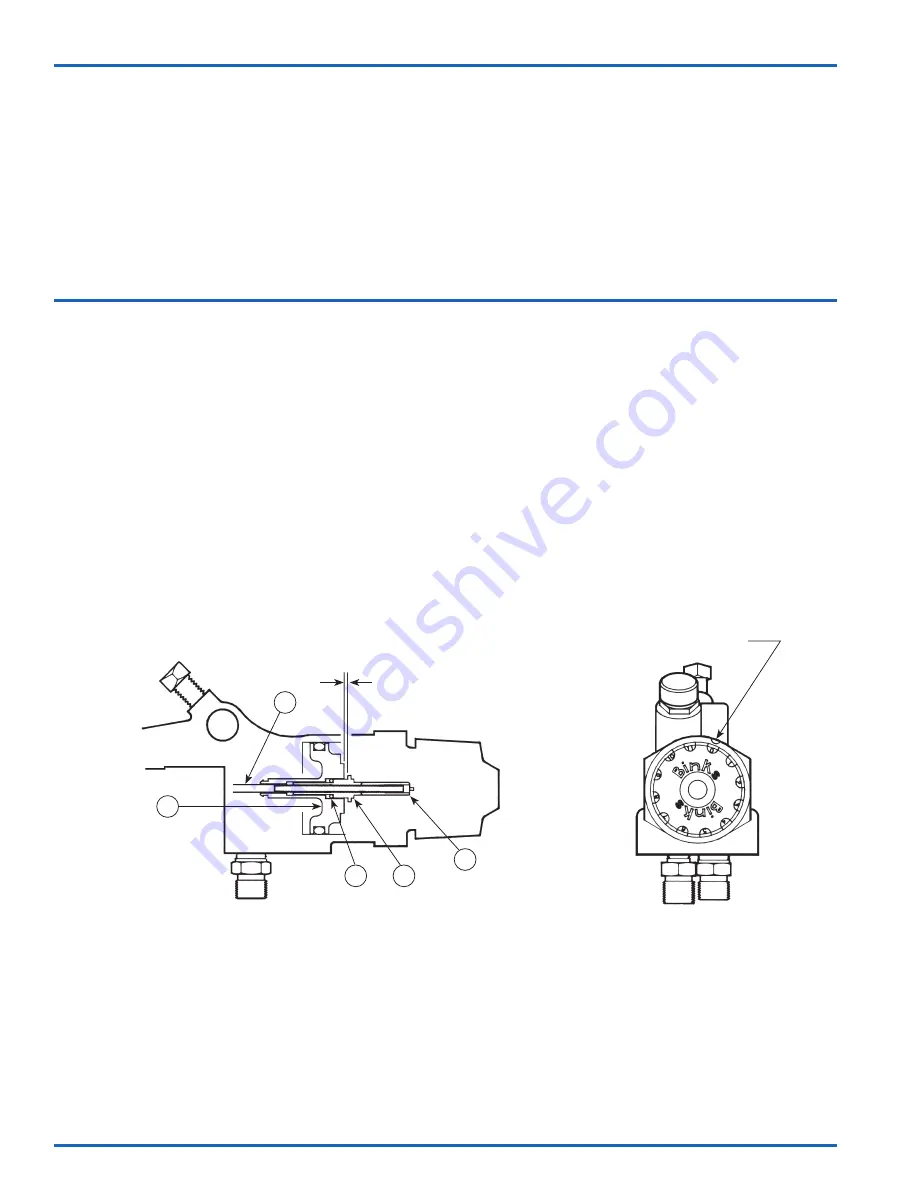

ADJUSTING AIR AND FLUID TIMING

A 1/16" gap between the air piston assembly (18) and

needle body (24) should be maintained (see figure 1).

This will create needle motion that will allow adequate

air flow before the fluid starts flowing. The gap may be

adjusted by partially removing the material needle (22),

screwing it either in or out of the needle body (24) and

locking it back into the gun while being sure to check

the clearance between the air valve piston (18) and the

needle body (24).

ADJUSTING THE SPRAY PATTERN

The width of the spray pattern is controlled by the side

port control assembly (7). (See page 6). Turning this

control clockwise until it is closed will give a round

spray; turning it counterclockwise will widen the spray

into a fan shape. The fan spray can be turned

anywhere through 360

°

by positioning the air nozzle

(2) relative to the gun. To effect this: loosen retaining

ring (1); position nozzle (2) then retighten

retaining ring.

Indicator notch

Rear

View

Figure 1

1/16" clearance

20

22

23

24

25

RATCHET ADJUSTMENT

1. First, note the number on the indicator notch (see

REAR VIEW above).

2. Remove ratchet housing assembly (28) and 2 springs

(26 & 27). Make sure needle body (24) is set with a

1/16" clearance as shown in figure 1. (To set 1/16"

clearance, see “ADJUSTING AIR AND FLUID TIMING”

above).

3. Remove screw (33) from inside the center of the

ratchet housing (29) and pull off cap (35).

4. Reset cap back onto ratchet housing assembly (28)

aligning the zero on the cap to the indicator notch

as shown in the REAR VIEW above.

5. Tighten screw (33) and reassemble springs and

ratchet housing assembly to gun. The needle should

now be closed and in the zero position.

NOTE:

All No’s. in parenthesis refer to Item No’s. in Assembly Drawing on Page 6.

EN

77-2672-R7.0 (8/2017)

8 / 16

www.carlisleft.com