IMPORTANT: Before using this equipment,

carefully read SAFETY PRECAUTIONS, starting on

page 1, and all instructions in this manual. Keep

this Service Manual for future reference.

MODEL: A12846-XX

PRODUCT MANUAL

CS-11-02.1

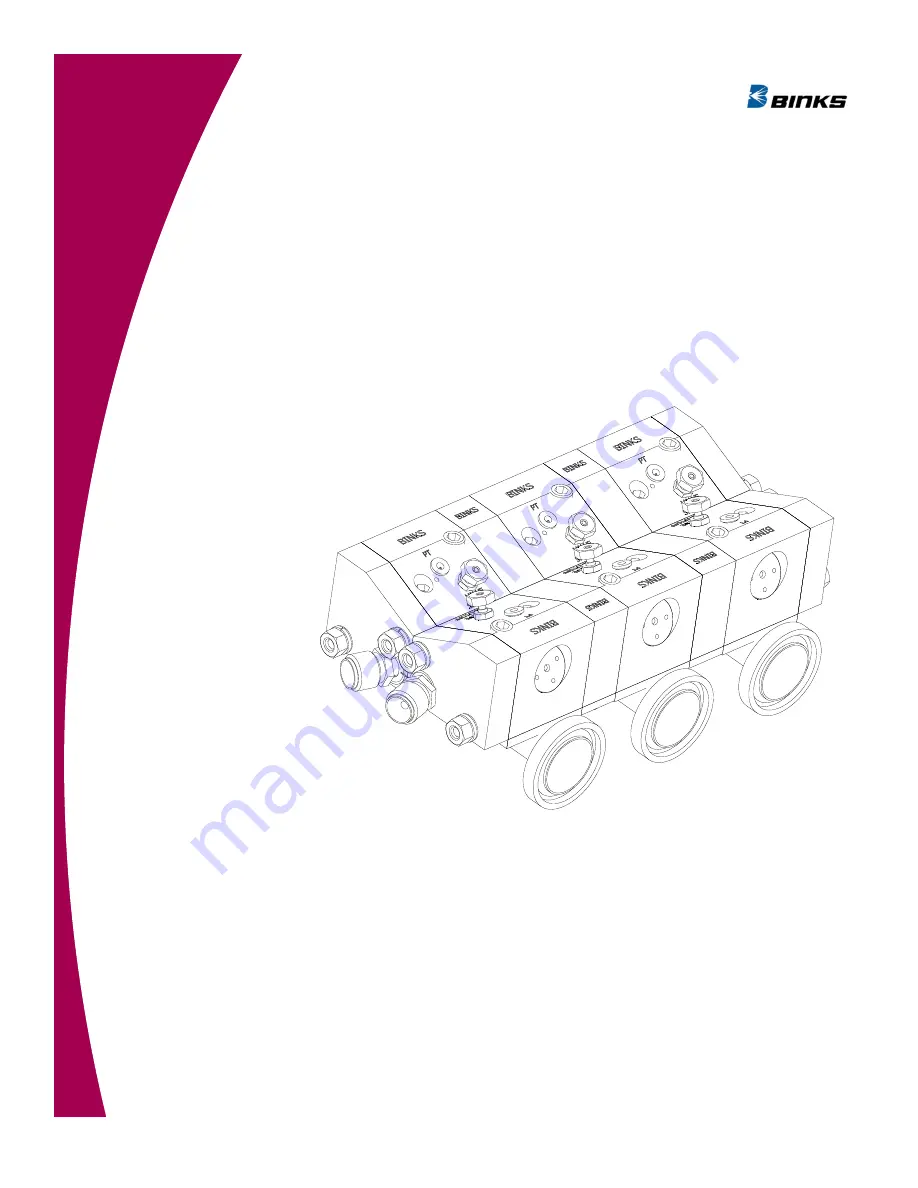

Inline/Piggable

Dual Modular Color Changer

Product Manual Price: $50.00