BC26 HYDRO-DRIVE Operator’s Manual

Part No 501530

6

501530_B_HI

PACKING CHECKLIST

Your BILLY GOAT

®

BC Self-Propelled Hydro-Drive Brush Cutter was shipped in one carton, completely assembled except for

the upper handle assembly and the front guard bar. Mounting hardware for the handle and guard bar is temporarily installed on

the lower handle and the front of the deck assembly. The throttle cable hardware is located on the bracket on the right side of

the handle

NOTE

: BC2601HHFT models are shipped completely assembled and will need to have the blade cable attached

before gas and oil is added to the machine. A CB18, C50, SC50 or MCB50 series dry or wet battery with a 17.2 Ah rating is

required when replacing the battery.

READ

all safety instructions before assembling unit.

PARTS BAG & LITERATURE ASSY

Warranty card P/N- 80102772, Owner’s Manual P/N-501530, General Safety and Warranty Manual P/N- 100296, Declaration

of conformity P/N 100502

ASSEMBLY

NOTE

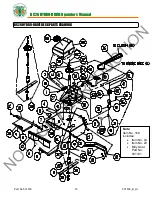

: Items in ( ) can be referenced in the Parts Illustrations and Parts Lists on pages 15-22.

1. REMOVE

unit from carton and check the contents of the parts bag with the list above.

2. REMOVE

mounting hardware from the hardware bag.

3. ATTACH

the handle to the engine base with items 72, 73, and 48.

4. TIGHTEN

mounting hardware on handle braces (items 5 and 6).

5. ATTACH

guard bar (item 16) to Skid bar by installing the side bolts into the top two holes on the skids with items 12, 9

and 8.

6. ATTACH

the throttle (item 82) to the right hand bracket (item 70) using the hardware items 83 and 84. Tighten securely

and make sure the cable isn’t binding. FOR ELECTRIC START MODELS, Attach the throttle to the bracket then remove

the starter switch (item 144) from the parts bag. Feed the wire harness (item 153) for the start switch into the box (item

143) through the bottom and attach the starter switch to it. Then press the switch into hole on the top of the box, making

sure it is seated properly. (See parts illustration pg. 23 for assembly)

7. ATTACH

the Blade drive cable to the lever and seat the plastic insert into the bracket on the left side of the handle.

8. SECURE

the drive and blade cables with the ty-wraps provided.

9. (ELECTRIC START ONLY)

For electric start models secure the battery in the battery plate (item 141), hook one side of

the strap (item 147) into the hole then stretch the strap across the top of the battery and hook the opposite side into the

opposing hole on the plate. Make sure the battery will not move then connect terminals. Replacement hardware to

attach the cables to the battery can be found at a local hardware store.

DISCONNECT

spark plug wire before assembling unit.

Boxing Parts Checklist

Owner’s Manual 501530

Upper Handle Assembly, P/N 501010, Electric model P/N 501009

Guard Bar, P/N 501403

Ty-Wraps P/N 900402 (qty 4)

Screwcap 3/8” – 16 X 2” P/N 8041054 (qty 4)

Washer 3/8” flat P/N 8171004 (qty 4)

Nut Lock 3/8”-16 P/N 8160003 (qty 4)

Nut lock #10-24 hex P/N 8164005 (qty 2)

Screw machine flat HD Phil P/N 830514 (qty 2)

Washer 5/16” flat P/N 8171003 (qty 4)

Bolt carriage 5/16”-18 x 1 3/4” P/N 8024043 (qty 4)

Nut Lock 5/18”-18 hex ZP P/N 8160002 (qty 4)

Starter switch P/N 501286 (Electric start only)

Engine Manual Per Model

Honda

NOT

FOR

REPRODUCTION