BC26 HYDRO-DRIVE Operator’s Manual

Part No 501530

11

501530_B_HI

NOTE

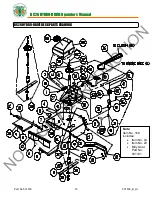

: See

Fig 12

for proper belt routing.

TRANSAXLE

DRIVE

BELT

REMOVAL

AND

REPLACEMENT

(See pages 21 and 22 for Parts Illustration and Parts

List)

BLADE

DRIVE

BELT

REMOVAL

AND

REPLACEMENT

(See page 15 and 16 for Parts Illustration and Parts list)

TRANSAXLE

DRIVE

ADJUSTMENT

DISCONNECT

spark plug wire before servicing unit.

DISCONNECT

spark plug wire before servicing unit.

DISCONNECT

spark plug wire before servicing unit.

Blade Drive Belt (with Transaxle

Belt not Shown)

LOOKING THROUGH TOP

Transaxle Drive Belt

(Seated below drive belt on

clutch)

1.

Disconnect spark plug wire.

2.

Lift and support the rear of the unit to allow access to the underside

3.

Detach the spring (item 50) from the bracket (item 98) that is keeping

tension on the drive belt. (See

Fig. 10

)

4.

Walk the belt (item 121) off of the clutch (item 54) by slowly pulling the

engine over.

WARNING

: use caution not to pinch fingers between the

belt and clutch.

5.

Slip the belt off of the transaxle pulley.

6.

Replace the belt in reverse order.

NOTE

: make sure the belt is seated

properly in the clutch and transaxle and make sure that it does not bend

over the fan blades on the transaxle.

Fig. 10

1.

Disconnect spark plug wire.

2.

Lift and support rear of unit to allow access to underside.

UNIT IS HEAVY

. Make sure support is adequate to support weight of

machine.

3.

Loosen the four screws (item 27) holding deck belt cover (item 29) and remove

cover.

4.

Follow the steps 3 and 4 in the Transaxle drive belt removal section to remove

the Transaxle drive belt. NOTE: It may be necessary to pry idler pulley (item

35) away from its original position to release belt, using a ratchet with an

extension in the square hole on the idler arm should allow the proper leverage

to pull it off the belt. (See

Fig. 11

)

5.

Relieve the tension on the blade belt by pulling the deck idler arm off of the belt.

Then walk the belt off of the deck pulley.

6.

Feed the belt back to the engine base then slip the belt off of the clutch.

7.

Install the new belt in reverse order making sure the belt is seated properly in

the clutch.

8.

Reconnect spark plug wire

Fig. 11

Fig. 12 – Belt

Routing Diagram

NOT

FOR

REPRODUCTION