- 40 -

INST

ALL

ATION

INSTALLATION

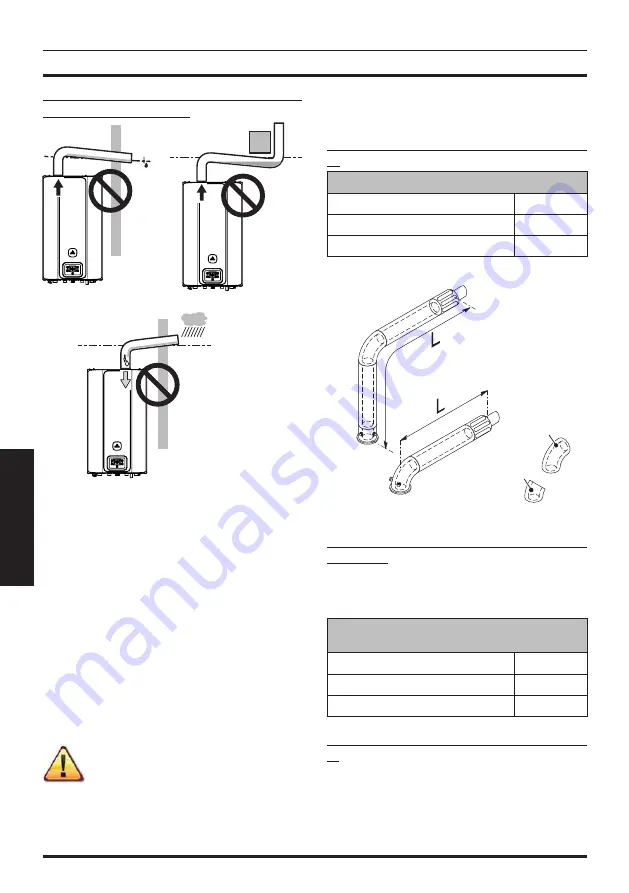

INCORRECT implementation of twin flue gas

outlet/air suction systems

Figure 5.10

S

A

S

A

= air suction

S

= flue gas outlet

5.9 Flue gas outlet dimensions and

lengths

The flue gas outlet/air suction can be set up in

the following ways:

C

13

C

33

C

43

C

53

C

63

C

83

C

93

B

23P

Consult the sheet provided with the selected kit

which is packaged separately.

The horizontal sections of the flue gas pipes must

have a slope of approx. 1.5 degrees (25 mm per

metre).

The terminal must be higher than

the boiler side opening.

Only the coaxial pipe with the terminal must

be horizontal as the discharge pipe has already

been implemented with the correct slope.

The following kits are available for connection to

the boiler:

Wall-mounted flue gas outlet kit (Figure 5.11

A)

Coaxial duct Ø 60/100 mm (A)

Nominal length

0.915 m

Minimum length

0.5 m

Maximum length

10 m

Figure 5.11

B

A

C

45°

90°

C13

Vertical flue gas outlet kit with 90° elbow (Fig-

ure 5.11 B)

This kit is used to raise the outlet axis of the boiler

by 635 mm.

The terminal must always discharge horizontally.

Coaxial duct Ø 60/100 with

90° elbow (B)

Nominal length

1.55 m

Minimum length

0.5 m

Maximum length

10 m

Supplementary 45° or 90° elbows (Figure 5.11

C)

Coaxial elbows Ø 60/100 mm.

When these elbows are used in the duct, they re-

duce the maximum length of the flue gas duct

by: