RCM

EDITION 07 / 2002

-

3

-

INDICE

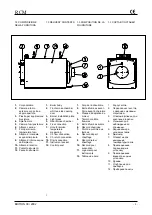

1. CARATTERISTICHE

TECNICHE

DIMENSIONALI

1.1 Caldaia RCM….….

4

1.2 Caratteristiche

generali…………….. 6

1.3 Composizione della

fornitura…………… 8

2. MONTAGGIO

2.1 Montaggio caldaia….. 9

2.2 Montaggio bruciatore 10

2.3 Montaggio

dell’isolamento e della

mantellatura……….. 12

3. INSTALLAZIONE

3.1 Impiantistica idraulica 15

3.2 Norme riguardanti

l’impianto…………... 16

3.3 Tubazioni di mandata e

ritorno acqua di

riscaldamento……… 17

3.4 Sicurezze, controlli e

regolazioni………...…18

3.5 Caratteristiche

dell’acqua…………… 18

3.6 Collegamenti elettrici 19

3.7 Centrale termica …… 23

3.8 Collegamento alla canna

fumaria……………… 24

4. BRUCIATORE

4.1 Bruciatore……...……. 26

5. AVVIAMENTO,

CONDUZIONE E

MANUTENZIONE

DELL’IMPIANTO

5.1 Riempimento

dell’impianto………. 27

5.2 Primo avviamento e

relativi controlli …… 27

5.3 Dati per il controllo della

combustione… …… 30

5.4 Norme generali per la

conduzione della

caldaia……………... 30

5.5 Norme di sicurezza e

controlli periodica .. 32

5.6 Norme generali per la

manutenzione…… 33

5.7 Disposizioni legislative

relative all’esercizio e

alla manutenzione… 35

6. ELENCO PRINCIPALE

NORME E LEGGI

APPLICABILI

6.1 Elenco principale norme

e leggi applicabile…. 37

TABLE OF CONTENTS

1. TECHNICAL

AND

DIMENSION

CHARACTERISTICS

1.1 RCM boiler ……..

4

1.2 General technical

characteristics……… 6

1.3 Delivery contents… 8

2. ASSEMBLY

2.1 Boiler assembly ...

9

2.2 Burner installation . 10

2.3 Insulation and casing

installation………. 12

3. ISTALLAZIONE

3.1 Plumbing system.… 15

3.2 Pipeline system…… 16

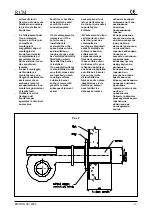

3.3 Heating water delivery

and return pipelines 17

3.4 Safety, control and

adjustment devices.. .18

3.5 Water characteristics 18

3.6 Electrical

connections……… 19

3.7 Heating plant…… 23

3.8 Connection to the

smokestack……

24

4. BURNER

4.1 Burner…………… 26

5. SYSTEM

START-UP,

OPERATION AND

MAINTENANCE

5.1 Filling the heating

system ………

27

5.2 First start-up and

preliminary checks.. 27

5.3 Data for checking

combustion…

30

5.4 General boiler operating

regulations………… 30

5.5 Safety regulations and

periodic checks…… 32

5.6 General maintenance

standards………

33

5.7 Operation and

maintenance…… 35

6. LIST

OF

PRINCIPAL

APPLICABLE

STANDARDS AND

LAWS

6.1 List of principal

applicable standards

and laws…………. 37

INDICE

1. CARACTERISTIQUES

TECHNIQUES ET

DIMENSIONNELLES

1.1 Chaudière RCM…

4

1.2 Description………… 6

1.3 Composition de la

fourniture…………

8

2. MONTAGE

2.1 Montage de la

chaudière ………… 9

2.2 Montage du brûleur. 10

2.3 Montage de l’isolation et

de la jaquette……… 12

3. MISE EN PLACE

3.1 Installation

hydraulique……… 15

3.2 Normes concernant

l’installation……… 16

3.3 Tuyaux de départ et de

retour de l’eau de

chauffage………… 17

3.4 Sécurité, contrôles et

réglages………….. 18

3.5 Caractéristiques de

l’eau……………

18

3.6 Raccordement

électrique………

19

3.7 Chaufferie………… 23

3.8 Raccordement au

conduit de fumée

24

4. BRÛLEUR

4.1 Brûleur…………… 26

5. MISE EN ROUTE,

EXPLOITATION ET

MAINTENANCE DE LA

CHAUDIERE

5.1 Remplissage de

l’installation …….…. 27

5.2 Première mise en route

et contrôles

correspondants .

27

5.3 Données pour le

contrôle de la

combustion……… 30

5.4 Normes générales pour

l’exploitation de la

chaudière………… 30

5.5 Normes de sécurité et

contrôles périodiques32

5.6 Normes générales pour

l’entretien………… 33

5.7 Disposition concernant

le fonctionnement et la

maintenance………. 35

6. LISTE

DES

PRINCIPALES

NORMES ET LOIS

APPLICABLES

6.1 Liste des principales

normes et lois

applicables……… 37

СОДЕРЖАНИЕ

1.

ТЕХНИЧЕСКИЕ

ХАРАКТЕРИСТИКИ

И

РАЗМЕРЫ

1.1

Котел

RCM ..…

4

1.2

Основные

характреристики

… 6

1.3

Состав

поставки

…………… 8

2.

МОНТАЖ

2.1

Монтаж

котла

..…… 9

2.2

Монтаж

горелки

…. 10

2.3

Монтаж

изоляции

и

обшивки

…….……. 12

3.

УСТАНОВКА

3.1

Гидравлическое

подключение

…… 15

3.2

Нормы

по

установке

…………. 16

3.3

Трубопровод

подачи

и

возврата

воды

для

отопления

………. 17

3.4

Безопасность

,

контроль

,

регулирование

……. 18

3.5

Характеристики

воды

………………… 18

3.6

Электрические

соединения

……… 19

3.7

Котельная

……

23

3.8

Присоединение

к

дымоходу

………… 24

4.

ГОРЕЛКА

4.1

Горелка

………… 26

5.

ЗАПУСК

И

ЭКСПЛУАТАЦИЯ

КОТЛА

5.1

Наполнение

котла

.. 27

5.2

Первый

запуск

и

соответствующий

контроль

…

27

5.3

Данные

по

контролю

горения

………..… 30

5.4

Основные

нормы

по

работе

котла

……………

30

5.5

Нормы

безопасности

и

периодический

контроль

……

32

5.6

Основные

нормы

эксплуатации

33

5.7

Нормативы

по

работе

и

эксплуатации

…… 35

6.

ОСНОВНОЙ

СПИСОК

НОРМАТИВ

И

ЗАКОНОВ

6.1

Основной

список

применяемых

норм

и

законов

…

37

Содержание RCM 105

Страница 2: ......