RCM

EDITION 09 / 2002

-

13

-

messa a terra della

caldaia al pannello

strumenti (4)

attraversando l’apposito

foro sul pannello (3)

5.

estrarre dal pannello

strumenti (4) i capillari

del termometro e dei

termostati e, attraverso

il foro del pannello

inserirli nell’apposito

pozzetto (5)

6.

fissare il pannello

strumenti al pannello

superiore (3) e montare

lo stesso sulla caldaia

7.

aprire il coperchio del

cruscotto porta

strumenti ed eseguire i

collegamenti elettrici

seguendo lo schema

ATTENZIONE!

-

Far passare i cavi

d’alimentazione del

pannello, della pompa

di circolazione e

dell’eventuale

collegamento del

termostato ambiente,

in idonei passacavi.

-

Per l’alimentazione del

bruciatore, utilizzare

cavo idoneo con

serracavo.

-

Collegare il filo della

messa a terra alla vite

contrassegnata con il

simbolo

-

Controllare

accuratamente il

fissaggio del

collegamento a terra, il

quale è obbligatorio e

deve corrispondere ai

parametri stabiliti dalle

norme CEI. La ditta

costruttrice non

risponde per danni a

persone o cose

derivanti dalla

mancata osservanza

di questa

fondamentale norma.

cable to instrument

panel (4) through the

hole in panel (3).

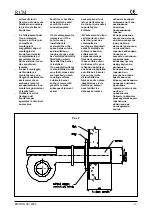

5.

unroll the capillary tubes

of the thermometer and

the thermostats out from

instrument panel (4) and

insert them in their

pocket (5) through the

hole in the panel.

6.

fasten the instrument

panel to top panel (3)

and install it on the

boiler.

7.

remove the instrument

control board cover and

make electrical

connections

ATTENTION!

-

Run the board,

circulation pump and

(if present) room

thermostat connection

supply cables through

the cable glands.

-

When bringing power

to the burner use the

cable gland.

-

Connect the ground

wire to the screw

marked with the

symbol

-

Carefully check the

ground connection.

This connection is

mandatory and must

comply standards EN

and local regulation

requirements. The

manufacturer will not

be responsible for

damage to persons or

property caused by

failure to comply with

this basic

requirement.

tableau de commande

(4) en traversant le trou

fait sur le panneaux (3).

5.

Dérouler délicatement

les capillaires des

sondes de température

et les engager dans le

doigt de gan.

6.

Fixer le tableau de bord

au tableau supérieur

et monter le même sur

la chaudière.

7.

Enlever le couvercle du

tableau de commandes

et exécuter les

branchements

électriques selon le

schéma

ATTENTION!

-

Faire passer les

câbles d’alimentation

du panneau, de la

pompe de circulation

et du branchement

éventuel du

thermostat d'ambiance

dans passes câbles.

-

Pour l’alimentation du

brûleur, utiliser câble

prévu pour ce service

-

Relier le fil de terre à

la vis repérée par le

symbole

-

Contrôler

soigneusement la

fixation de la

connexion de mise à

la terre, qui est

obligatoire et doit

correspondre aux

conditions visées par

les normes NF-C1500.

La firme constructrice

ne répond pas des

dommages causés

aux personnes ou aux

choses par suite de

l’inobservation de

cette norme

fondamentale.

заземление

к

приборной

панели

(4)

через

соответствующее

отверстие

на

панели

(3).

5.

Снять

с

приборной

панели

(4)

капилляры

термометра

и

термостатов

и

через

отверстие

на

панели

вставить

их

в

соответствующее

углубление

(5).

6.

Зафиксировать

приборную

панель

на

верхней

панели

(3)

и

установить

последнюю

на

котел

.

7.

Открыть

корпус

приборной

панели

и

провести

электрические

присоединения

согласно

схеме

.

ВНИМАНИЕ

-

Проводить

питание

панели

,

циркуляционного

насоса

и

возможного

соединения

с

термостатом

окр

.

среды

в

соответствующих

кабельных

проходах

.

-

Для

питания

горелки

использовать

соответствующий

кабель

с

кабельным

зажимом

.

-

Соединять

заземление

с

винтом

,

на

который

нанесен

символ

.

-

Аккуратно

проверить

фиксаж

заземления

,

который

обязателен

и

должен

соответствовать

параметрам

,

установленным

нормами

CEI.

Фирма

–

производитель

не

несет

ответственности

за

вред

,

причиненный

людям

или

имуществу

из

-

за

несоблюдения

этой

основной

нормы

.

Содержание RCM 105

Страница 2: ......