BGS technic KG

Bandwirkerstr. 3

D-42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

www.bgstechnic.com

© BGS technic KG, Copying and further use not allowed

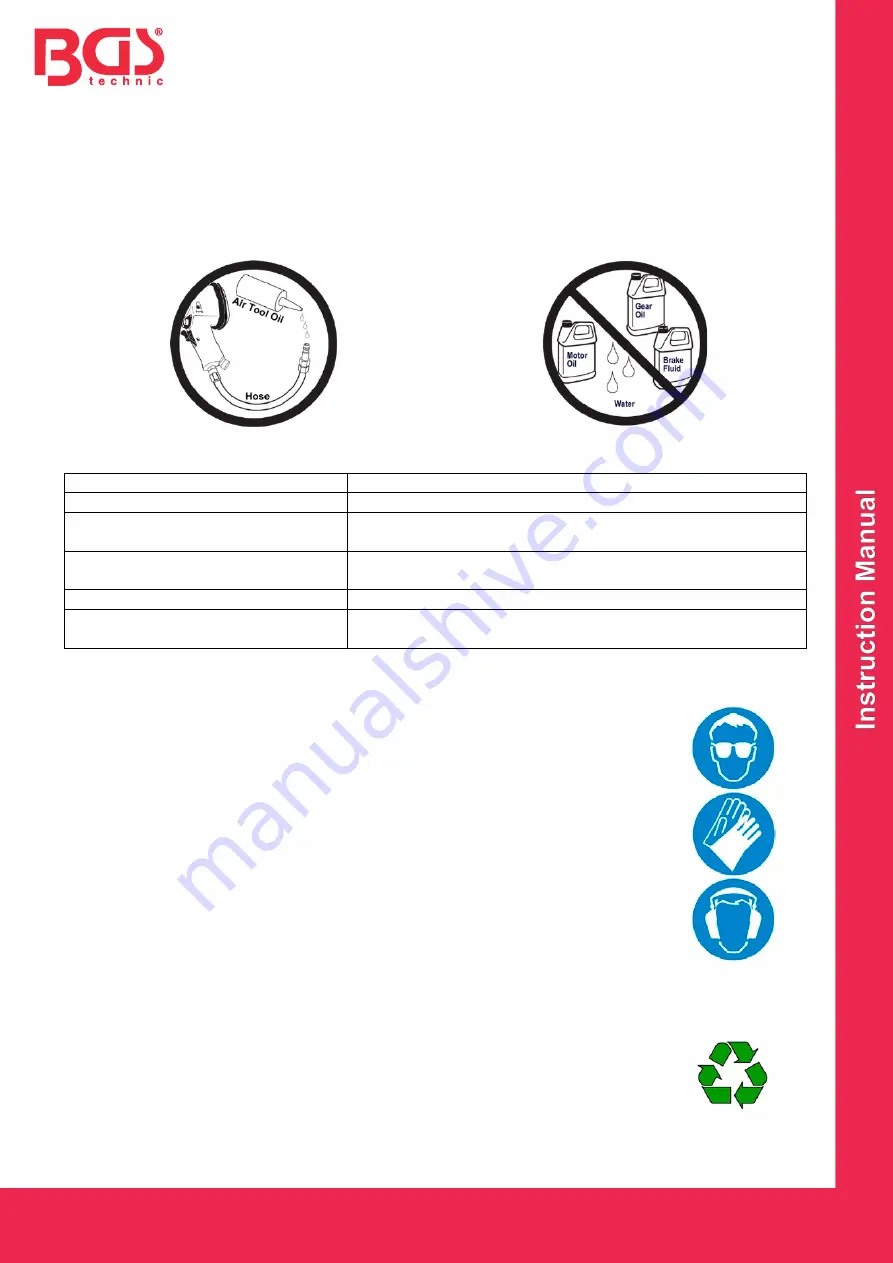

LUBRICATION & MAINTENACE

•

Oil the tool before each use with 4 to 5 drops air tool oil, placed in the air inlet is sufficient.

•

Use proper air pressure and CFM rating listed for this tool.

•

Drain water from hoses and compressor tank.

•

Water in the air supply system damaged the tool and loss of power.

•

Clean or replace air filters at prescribed intervals from.

TROUBLESHOOTING (

I

nsufficient power)

Probable Cause

Solution

Dirty or clogged air passages

Flush and lubricate tool, drain air tank and supply line

Insufficient air supply

Increase line pressure, make sure compressor matches

tool's air pressure and consumption needs

Air leakage

Use Teflon tape at all fittings and joints.

Check tool for worn or damaged O-rings & seals.

Worn / damaged wear & tear parts

Replace as necessary

Tool matching

Be sure you are using a tool suited for the sanding

requirements of the job at hand.

ATTENTION

During operation safety goggles and gloves should always be worn to

guard against flying rust and chips.

Always wear hearing protection during operation this air tool for a longer time.

Use only cutting discs rated at 12.000 RPM or higher.

ENVIRONMENTAL PROTECTION

Recycle unwanted materials instead of disposing of them as waste. All tools,

accessories and packaging must be sorted, taken to a recycling point and

disposed of in an environmentally friendly manner.

DISPOSAL

Dispose of this product at the end of its service life in accordance with your

region's disposal regulations. Ask your local waste agency about recycling

measures.

Содержание 3287

Страница 17: ......