English - 2

Working safely with this ma-

chine is possible only when the

operating and safety information

are read completely and the in-

structions contained therein are

strictly followed. In addition, the

general safety rules in the safety

rules section must be observed.

■

Wear safety goggles.

■

The dust that is produced while working can be

detrimental to health, inflammable or explo-

sive. Suitable safety measures are required.

Examples: Some dusts are regarded as carci-

nogenic. Use suitable dust /chip extraction and

wear a dust respirator.

Dust from light alloys can burn or explode. Al-

ways keep the workplace clean, as blends of

materials are particularly dangerous.

■

If the mains cable is damaged or cut through

while working, do not touch the cable but im-

mediately pull the mains plug. Never use the

machine with a damaged cable.

■

Connect machines that are used in the open

via a residual current device (RCD) with an ac-

tuating current of 30 mA maximum. Use only

extension cables that are approved for outdoor

use.

■

The machine can be used only for dry sanding.

■

Insert the mains plug only when the machine is

switched off.

■

Always direct the cable to the rear away from

the machine.

■

Do not work with materials containing asbes-

tos.

■

Always switch the machine off and wait until it

has come to a standstill before placing it down.

■

Never allow children to use the machine.

■

Berner is only able to ensure perfect operation

of the machine if the original accessories in-

tended for it are used.

■

Before any work on the machine itself, pull

the mains plug.

Selecting the sanding disc

Depending on the material to be worked, different

sanding sheet qualities are to be used.

Replacing the Sanding Disc

Before placing on a new sanding sheet, free the

sanding plate from dust and dirt.

To ensure optimum dust extraction, the holes of

the sanding sheet must match with those of the

sanding plate.

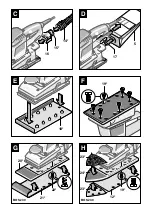

Sanding Sheet with Velcro Attachment

(see figure

)

The sanding sheets are placed directly onto the

sanding plate. The hole pattern in the sanding

plate and sanding sheet must match.

Sanding Sheets without Velcro Attachment

(see figure

)

Lightly lift the clamping lever 6 and unlatch it.

Slide the sanding sheet 13 under the open

clamping bracket 8 (

➊

) and reinsert the clamping

lever 6 (

➋

).

Make sure that the sanding sheet 13 lies taut on

the sanding plate. Fold the sanding sheet around

and clamp the other end in the same manner.

Sanding sheets without holes, e. g. from rolls or

by the meter, can be punctured with the perforat-

ing tool 18* for use with dust extraction (see

figure ).

The standard sanding plate 7 with velcro backing

can be exchanged against various specialty

sanding plates (accessories).

For this, unscrew the six screws 19 with a screw-

driver and remove the sanding plate.

Attach the desired sanding plate and insert

screws 19, or 22 respectively, when using the

thin, extended sanding plate 20.

For Your Safety

Replacing the Sanding Disc

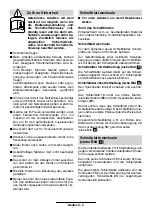

Replacing the Sanding Plate

(see figure

)

A

B

E

F