2

3

1 INTRODUCTION

Page 2

2 TECHNICAL SPECIFICATIONS

Page 3

3 PROFIBUS INTERFACE

Page 3

3.1

HARDwARE DESCRIPTION

Page 3

3.2

CABLE TyPE

Page 4

3.3

FIELDBUS CONNECTION

Page 4

3.4

SET-UP

Page 5

3.5

DISPLAy INDICATION OF FIELDBUS COmmUNICATION STATUS

Page 5

3.6

EmERgENCy SUPPLy

Page 6

3.7

PROFIBUS DP ARCHITECTURE

Page 6

4 CONTROLS AND INDICATIONS

Page 8

4.1

CONTROLS

Page 8

4.2

ACTUATOR FEEDBACk INDICATION

Page 11

5 ACyCLIC COmmUNICATION

Page 18

CONTENTS

1

INTRODUCTION

Profibus DP is an industrial fieldbus which allows connecting actuators and other devices (sensors …)

to a Distributed Control System (DCS) or a Programmable Logic Controller (PLC). Many actuators and

other devices can be connected on a single or redundant fieldbus line provided they are all equipped

with a compatible Profibus interface.

The Profibus DPV1 interface described in this document has been specially designed for the Bernard

actuators with control. This interface is compliant with Profibus DP (V0) and Profibus DPV1.

Profibus DP (V0) runs cyclic communication when Profibus DPV1 runs in addition acyclic messages.

Redundant communication

The redundant version is specially interesting to ensure a communication continuity even if one line

disrupted or if one interface board is out of order for any reason.

In case of a redundant fieldbus, the PLC must be able to manage 2 fieldbus lines.

Two Profibus interface boards are built in the actuator with isolated connections to the Profibus

lines.

In case of failure along a line, the PLC can still communicate through the other line.

Redundancy is also available with specific monitoring «RedCom with redundancy extensions» that

can be used if the PLC can support the same extensions.

According to the fieldbus version required an INTELLIBUS, single or redundant line, may equip the

actuator.

Control box with inside Profibus DP interface could be supplied to connect other equipment.

Please make sure to get and read the instructions for start-up (ref.NR1151) prior going

further with the setting of the Intellibus interface.

2

TECHNICAL SPECIFICATIONS

- The INTELLIBUS, a PROFIBUS-DPV1 slave module, can be controlled by a master PROFIBUS-

DP: PLC, PC, DCS or other interface boards from various suppliers.

- Hardware communication standard: RS 485.

- Automatic speed selection: 9,6K….1.5M bauds.

- Actuator addresses from 1 to 125 (one address is used by the master)

- Maximum number of actuators by line: 31 (up to 124 with repeaters).

- 2 versions: single channel or redundant channel

- CE Conformity.

- GSD file name:

For single line board

LBVS0ACC.GSD

For redundant line board

Classical

redundancy

line

LBVR0ACC.GSD

RedCom with redundancy extensions LBRE0ACC.GSD

- Fieldbus is electrically totally isolated from the actuator circuitry. In case of a redundant

version, each input is electrically isolated from the actuator circuitry and are isolated from

each other.

- A loss of actuator power supply does not lead to a fieldbus disruption.

- Temperature working range is the same as the actuator one.

3

PROFIBUS INTERFACE

3.1

HARDwARE DESCRIPTION

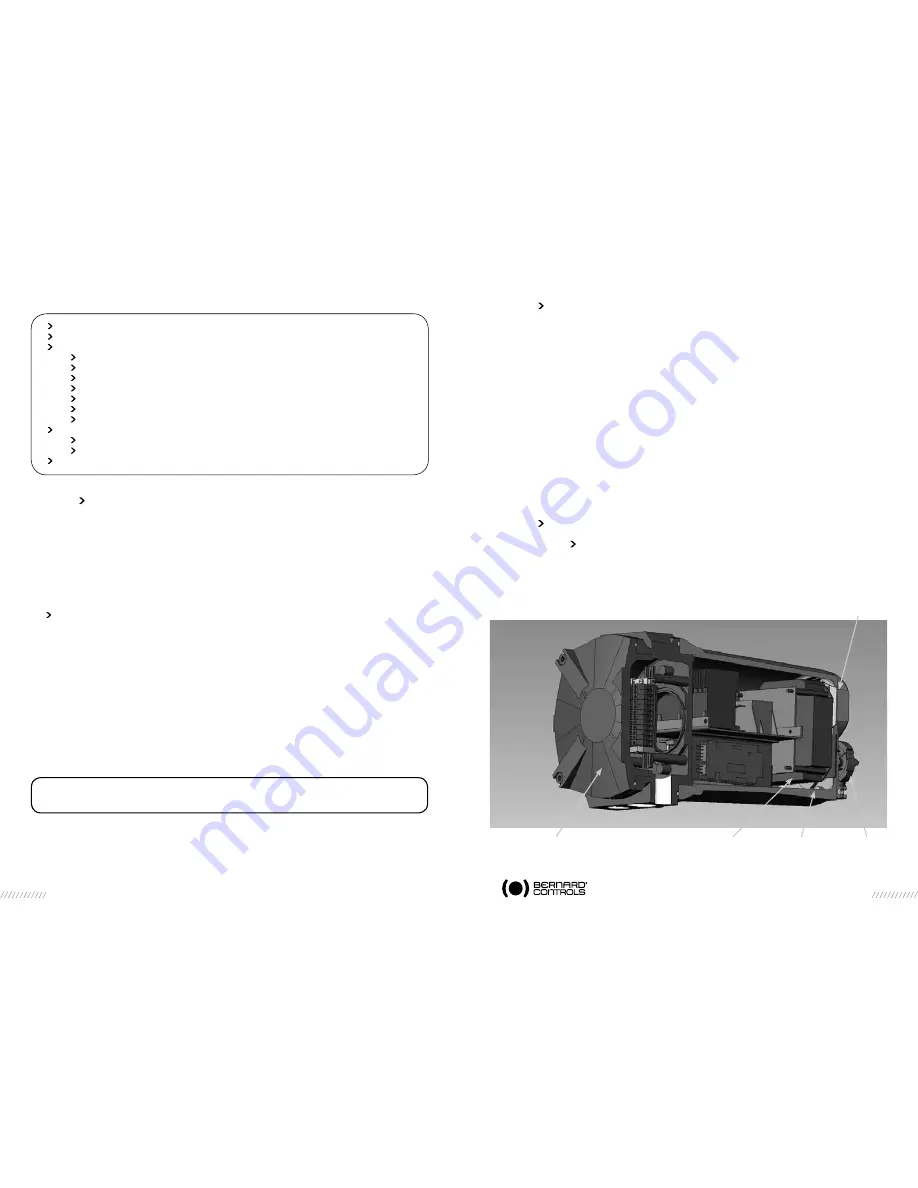

The Profibus module « Intellibus « located in the actuator is plugged on to the main board

and no access is needed.

fpX: explosion proof box

As far as actuators with I, or controls are concerned,

please refer to the Profibus DP for I instructions for start-up (NR1148).

Connection box

INTELLIBUS board

board

Button for

local control

Display