5

Installation

Risk of electric shock. Can shock, burn or

kill. Ground pump motor correctly before connecting

to power supply, per article 250-80 of the National

Electrical Code (NEC) in the U.S., or the Canadian

Electrical Code (CEC), as applicable.

Location

Locate pump in a dry, well ventilated area, not subject to

freezing or extreme variations in temperature.

Mount pump a minimum of 6” from any obstruction

or hot surface. Install the pump with the motor shaft

vertical. Make sure that an adequate supply of cool air

reaches the motor cooling fan. Maximum ambient air

temperature is 104° F (40° C).

For open systems requiring suction lift, locate the pump

as close to the water source as possible.

Foundation

Foundation should be concrete or a similarly rigid

foundation to provide a secure, stable mounting base for

the pump.

Secure pump to foundation using all bolt holes. Refer to

Figures 2 and 3 for bolt plate dimensions. Be sure that all

four pads on the base are properly supported.

Shim pump base to make sure that pump is level.

Piping

Risk of explosion and scalding. Do not run

pump with discharge valve closed; the water in the

pump may boil, with risk of explosion and steam burns

to anyone near.

If there is any danger of the pump running against a

closed discharge valve, install a pressure relief or by-pass

valve in the discharge pipe to allow for minimum liquid

flow through the pump. Minimum liquid flow through

the pump is needed for cooling and lubrication of the

pump (See Table IV). Run the bypass/relief valve and

discharge pipe to a floor drain or a tank for collection.

Suction pipe should be adequately sized (See Table V)

and run as straight and as short as possible to keep

friction losses to a minimum. Pipes, valves, and fittings

must have a pressure rating equal to or greater than the

maximum system pressure.

Pressure check the discharge piping as required by codes

or local regulations.

“Inlet” and “Outlet” are marked on the pump base to

show the direction of the liquid flow through the pump.

Install anti-vibration mountings on either side of the

pump if a minimum noise level is desired.

Install isolation valves in both inlet and outlet pipes near

the pump (see Figure 5). This allows for removal of pump

for service without draining the system and isolation of

the pump in case of a flooded suction condition.

TABLE IV – Minimum Pumping Rates

Type

Liquid Temperature

+5° F to +250° F

BVM2

1 GPM

BVM4

2 GPM

BVM8

4 GPM

BVM16

8 GPM

TABLE V – Minimum Suction Pipe Sizes

Type

Pipe Size

BVM2

1-1/4” Nominal Diameter, Schedule 40 Pipe

BVM4

1-1/4” Nominal Diameter, Schedule 40 Pipe

BVM8

2” Nominal Diameter, Schedule 40 Pipe

BVM16 2” Nominal Diameter, Schedule 40 Pipe

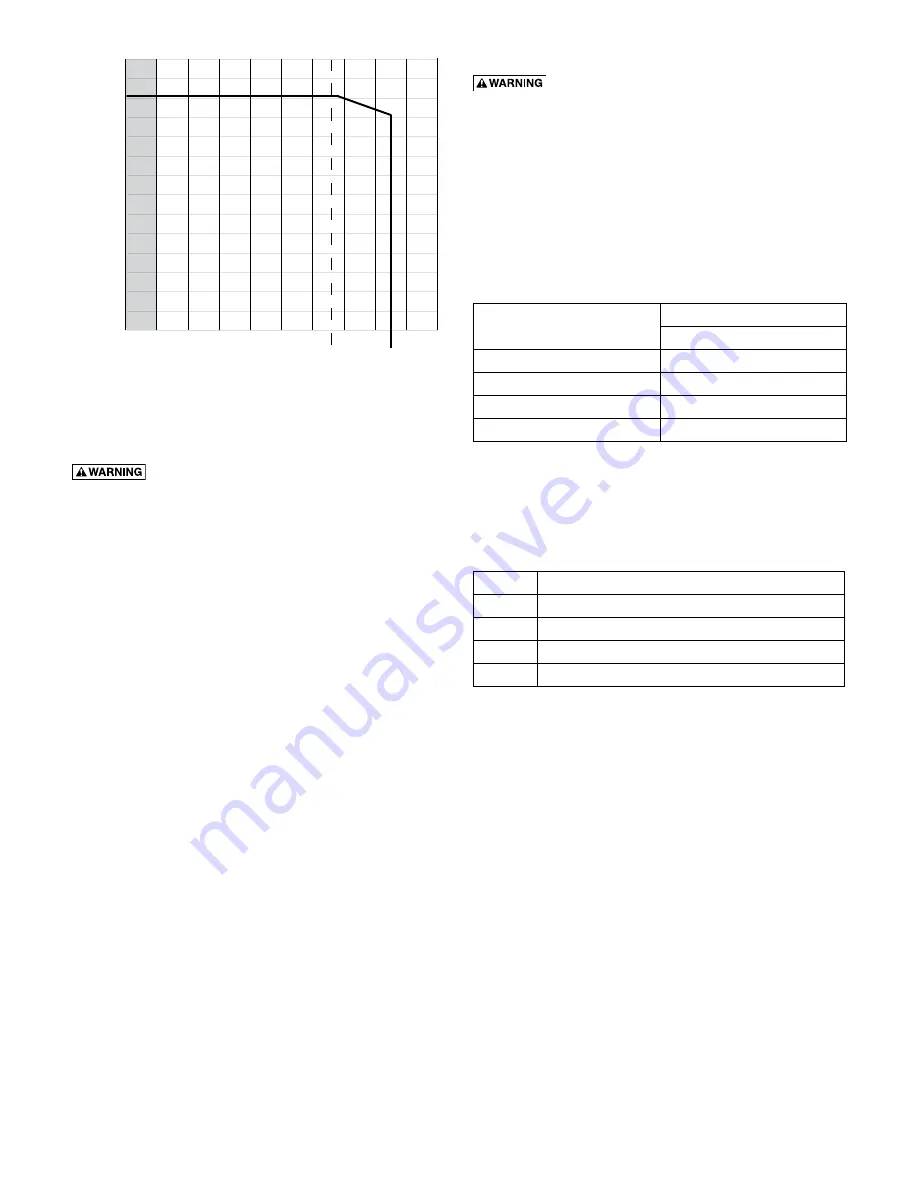

Figure 4 - Maximum Permissible Operating Pressure - all

BVM models

0

30

60

90

120

150

180

210

240

270

300

330

360

390

420

212

0 to100 120 140 160 180 200 220 240

250

260 280

Pressure in PSI

Temperature in Degrees F

3 98