RJW Series of Rolling Jacks

8

P/N 5900093 — Rev. B — October 2020

Frequently Asked Questions

Question

: What kinds of Vehicles can I raise on my Rolling Jack?

Answer

: A wide range of Vehicles. There are multiple Rolling Jack models, each supporting different

weight capacities, so a wide range of Vehicles can be raised.

Q

: If a Vehicle is already raised on a four-post Lift, why do I need a Rolling Jack?

A

: A Rolling Jack gives you the option of raising two or four wheels of the Vehicle off the Runway,

which makes certain automotive services (brake jobs, suspension work, tire changes, and so on)

easier. Each Rolling Jack can raise two wheels of the Vehicle via its axle, so to get

four wheels

off

the Runway, you need

two

Rolling Jacks.

Q

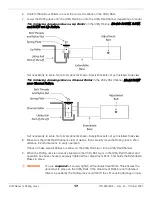

: How does a Rolling Jack work?

A

: Each Rolling Jack gets positioned between the Runways of a four-post Lift, such as an HD-9. They

are used to raise the front or the rear of the Vehicle up off the Runway, via their axles. Having the

Wheels off the Runways makes it easier to perform certain automotive services.

Q

: What Rolling Jack goes with what BendPak Lift?

A

: Rolling Jacks are associated with specific BendPak Lifts, based on weight capacities. So if you

have a BendPak HD-

14

Lift, for example, you would need

two

RJ

7

W Rolling Jacks. Each Jack can

only raise up to half of the weight for which the Lift is rated.

Q

: Can I use a Rolling Jack on an Alignment Lift?

A

: Yes. They work the same on an Alignment Lift.

Q

: Are Rolling Jacks heavy?

A

: Yes. You need a Shop Crane or Forklift to put them into position and you must not stand or walk

under them. Your Rolling Jack was designed to stay in place, but you should always use extreme care

when walking around under Lifts, raised Vehicles, and Rolling Jacks.

BendPak strongly

recommends walking around rather than under any raised Vehicle

.

Q

: Why are the bases of a Rolling Jack extendable?

A

: To accommodate different widths between Runways on some four-post Lifts.

Q

: How is a Rolling Jack powered?

A

: Via air pressure (that you supply) that connects to the Air-Operated Hydraulic Pump. The optional

Air Line Kit (5174009) makes this easy; visit

Q

: How many Safety Lock positions does my Rolling Jack have?

A

: Three. This gives you three heights to which you can raise and hold the Vehicle, whichever is best

for the work you want to do.

Q

: How long can I leave a Vehicle raised on my Rolling Jack?

A

: For quite some time, as long as long as you leave the Rolling Jack engaged on its Safety Locks.

Once the Safety Locks are engaged, gravity holds the Vehicle up, so a loss of air pressure has no

impact; your Vehicle is going to stay where you left it.

Always leave your Rolling Jack either

fully lowered or engaged on its Safety Locks.

Содержание RJ45LP

Страница 30: ...RJW Series of Rolling Jacks 30 P N 5900093 Rev B October 2020 Labels...

Страница 31: ...RJW Series of Rolling Jacks 31 P N 5900093 Rev B October 2020...

Страница 32: ...RJW Series of Rolling Jacks 32 P N 5900093 Rev B October 2020 Parts Sheets...

Страница 33: ...RJW Series of Rolling Jacks 33 P N 5900093 Rev B October 2020...

Страница 34: ...RJW Series of Rolling Jacks 34 P N 5900093 Rev B October 2020...

Страница 35: ...RJW Series of Rolling Jacks 35 P N 5900093 Rev B October 2020...

Страница 36: ...RJW Series of Rolling Jacks 36 P N 5900093 Rev B October 2020...

Страница 37: ...RJW Series of Rolling Jacks 37 P N 5900093 Rev B October 2020...

Страница 38: ...RJW Series of Rolling Jacks 38 P N 5900093 Rev B October 2020...

Страница 39: ...RJW Series of Rolling Jacks 39 P N 5900093 Rev B October 2020...

Страница 40: ...RJW Series of Rolling Jacks 40 P N 5900093 Rev B October 2020...

Страница 41: ...RJW Series of Rolling Jacks 41 P N 5900093 Rev B October 2020...

Страница 42: ...RJW Series of Rolling Jacks 42 P N 5900093 Rev B October 2020 Maintenance Log...

Страница 44: ...1645 Lemonwood Drive Santa Paula CA 93060 USA 2020 BendPak Inc All rights reserved bendpak com...