4

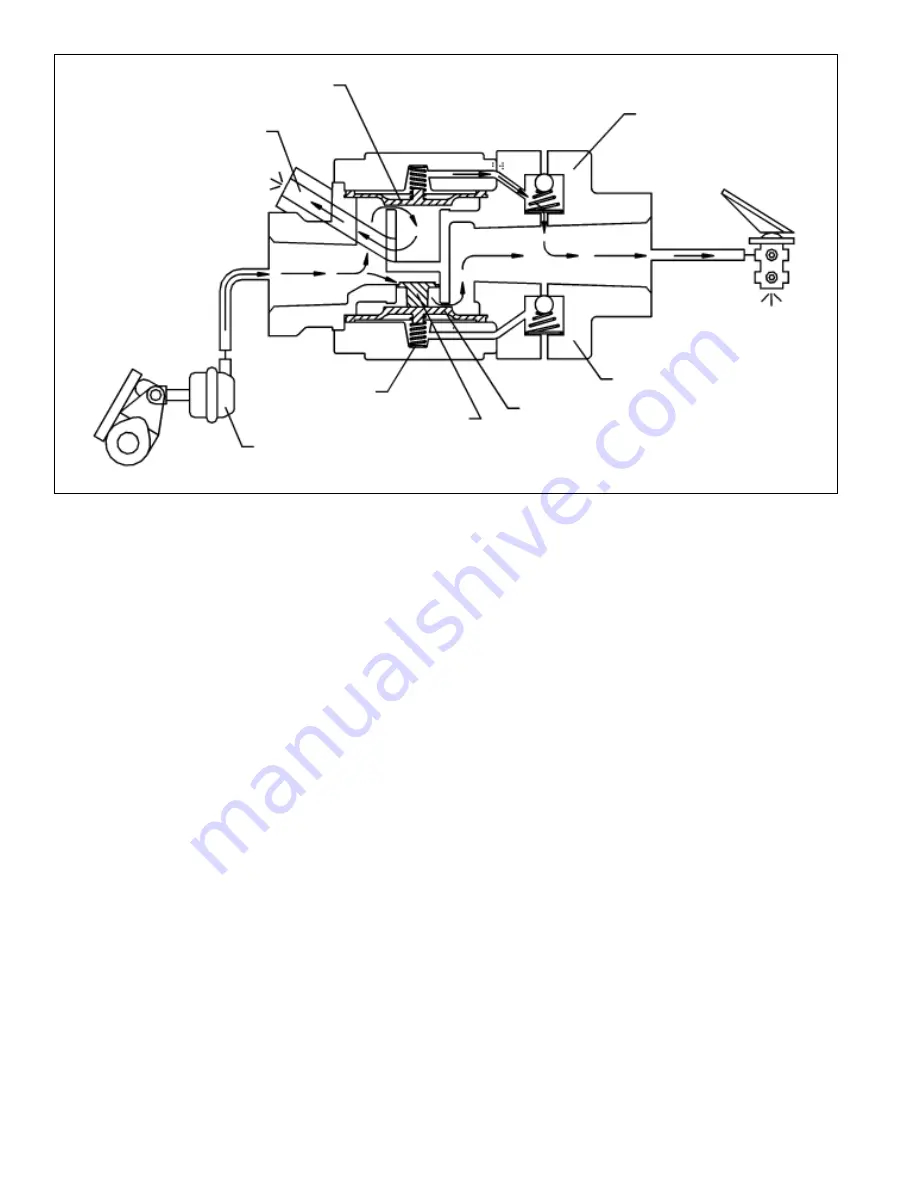

Rapid Exhaust

(Figure 8) -

The Rapid Exhaust operation

described in the following text occurs when the modulator is

controlling service chamber(s). During a very rapid brake

release the modulator will exhaust air in a different manner.

An example of this would be the case if the driver made a

severe brake application then lifted his foot from the foot

valve. During a rapid brake release, the rapid return of air

from the brake chamber to the supply port lifts the bias valve

from its normal position. The bias valve orifices the return

air which induces differential pressure across the exhaust

diaphragm. This differential pressure lifts the exhaust

diaphragm from its seat. Returning air flows past the open

exhaust and out the modulator exhaust port.

ANTILOCK OPERATION

GENERAL

If a service brake application is made and the antilock system

detects an impending wheel lockup, the antilock controller

will immediately begin modification of the brake application

using the modulator.

In order to modify the brake application, the coils of the two

solenoid valves contained in the modulator are energized or

de-energized in a preprogrammed sequence by the antilock

controller. When a solenoid coil is energized, and depending

whether the exhaust or hold solenoid is energized, it either

opens or closes, thereby causing the exhaust or

reapplication of air pressure to the brake actuator. The

solenoids in the modulator are controlled independently by

the antilock controller. By opening and closing the solenoid

valves in the modulator, the antilock controller is able to

simulate what the driver does when he pumps the brakes. It

must be remembered, however, that unlike the driver the

antilock controller is able to cycle each modulator, along

with the brakes connected to it, independently and with far

greater speed and accuracy.

ANTILOCK EXHAUST

(FIGURE 9)

When wheel lock is detected or imminent, the antilock

controller simultaneously energizes both the supply and

exhaust solenoids in the modulator. Energizing the supply

solenoid causes its exhaust to close and its inlet to open.

With the inlet of the supply solenoid open, application air is

permitted to flow to the control side of the supply diaphragm.

Air pressure acting on the supply diaphragm causes it to

close the supply and prevent further delivery of air to the

brake chamber.

Energizing the exhaust solenoid closes its inlet and opens

its exhaust. By closing the exhaust solenoid inlet, application

air is prevented from flowing to the control side of the exhaust

diaphragm. Air pressure which was present on the control

side of the exhaust diaphragm flows out the exhaust port of

the modulator. With control air pressure removed from the

exhaust diaphragm, brake application air forces the exhaust

diaphragm to unseat, allowing it to flow out the modulator

exhaust port. The modulator will remain in the antilock

exhaust mode until the antilock controller senses that wheel

speed has increased. The modulator can enter the antilock

hold or reapply mode from the antilock exhaust mode.

FIGURE 7: M-30

™

MODULATOR NON ANTILOCK EXHAUST OF SERVICE BRAKES (NORMAL)

BRAKE VALVE

SPRING

SUPPLY OR

HOLD

DIAPHRAGM

HOLD

VALVE

BIAS

VALVE

EXHAUST

DIAPHRAGM

EXHAUST

VALVE

BRAKE

CHAMBER

EXHAUST PORT