Start /

Stop

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

C

N

L

NO 15V S+S- P+ P-

T+ T-

A

B

GND

A

B

GND

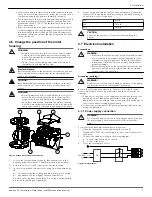

Figure 4: Connection diagram

For cable terminations, see above connection diagram.

4.7.2 I/O connections

1.

Open the terminal box cover removing the screws (5). Refer to fig-

ure 2 on page 7. Use control screwdriver described under section

4.2 to access terminal blocks.

2.

Connect the appropriate wires according to the terminal block di-

agram and the requirements of section

Connection assignment

(page 8) given below in section 4.7.3.

3.

Close the terminal box cover.

• For a two-pump connection, wire them through a communication

cable connecting the 2 RS-485 ports at the pumps to terminals 15,

16 & 17.

4.7.3 Connection assignment

• For all electrical connections use heat resistant wires or cable rat-

ed for at least 194°F (90°C). The cables should not touch the mo-

tor housing, the pump or the piping.

• Power and control wires must be run in separate channels.

• Metal conduit for power wiring must only be attached to 1/2” NPT

conduit fitting.

NOTICE:

Cable glands are only available for low voltage wiring to protect

against cable slippage and vapor ingress into the terminal box.

5 System Description

5.1 User interface

9

8

7

6

5

4

2

1

3

Figure 5: User interface diagram

1.

Control mode button

2.

Control mode indicators

3.

Parameter button

4.

Parameter indicators

5.

Setting buttons

6.

Numeric display

7.

Power indicator

8.

Status / Fault indicator

9.

Remote control indicator

Hot Surface:

Burn hazard. During the normal operation, the pump surfa-

ces may be so hot that only the buttons should be touched to

avoid burns.

5.1.1 User interface locking/unlocking

The user interface will automatically lock if no button is pressed for ten

minutes, or if the upper setting button (5) and the parameter button (3)

are pressed for two seconds. See

User interface

(page 8).

If a button is pressed when the user interface is locked, the display (6)

shows:

To unlock the user interface, press the upper setting button (5) and the

parameter button (3) for two seconds. The display (6) will show:

Now it is possible to change the pump setting as preferred.

5.2 Functions

The main functions of the pump and control modes are selectable

through the pump user interface and the embedded I/O. Advanced

functions or communication features, can only be set via bus protocol

or the optional Wireless module. See the advanced functions manual at

www.bellgossett.com.

5.2.1 Control mode

Mode

Description

Constant pressure

Hset

The pump maintains a constant

pressure at any flow demand. The

desired head of the pump can be

set via user interface. See section

6.1.2 Change set point.

5 System Description

8

ecocirc XL Installation, Operation, and Maintenance manual

Содержание ecocirc XL

Страница 1: ...Installation Operation and Maintenance manual ecocirc XL ...

Страница 2: ......