INTEGRA® / E-1063

5-2

Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL102

Chapter 5 Operator Interface/Wash Setup Screens

Setup

Setup / Packages

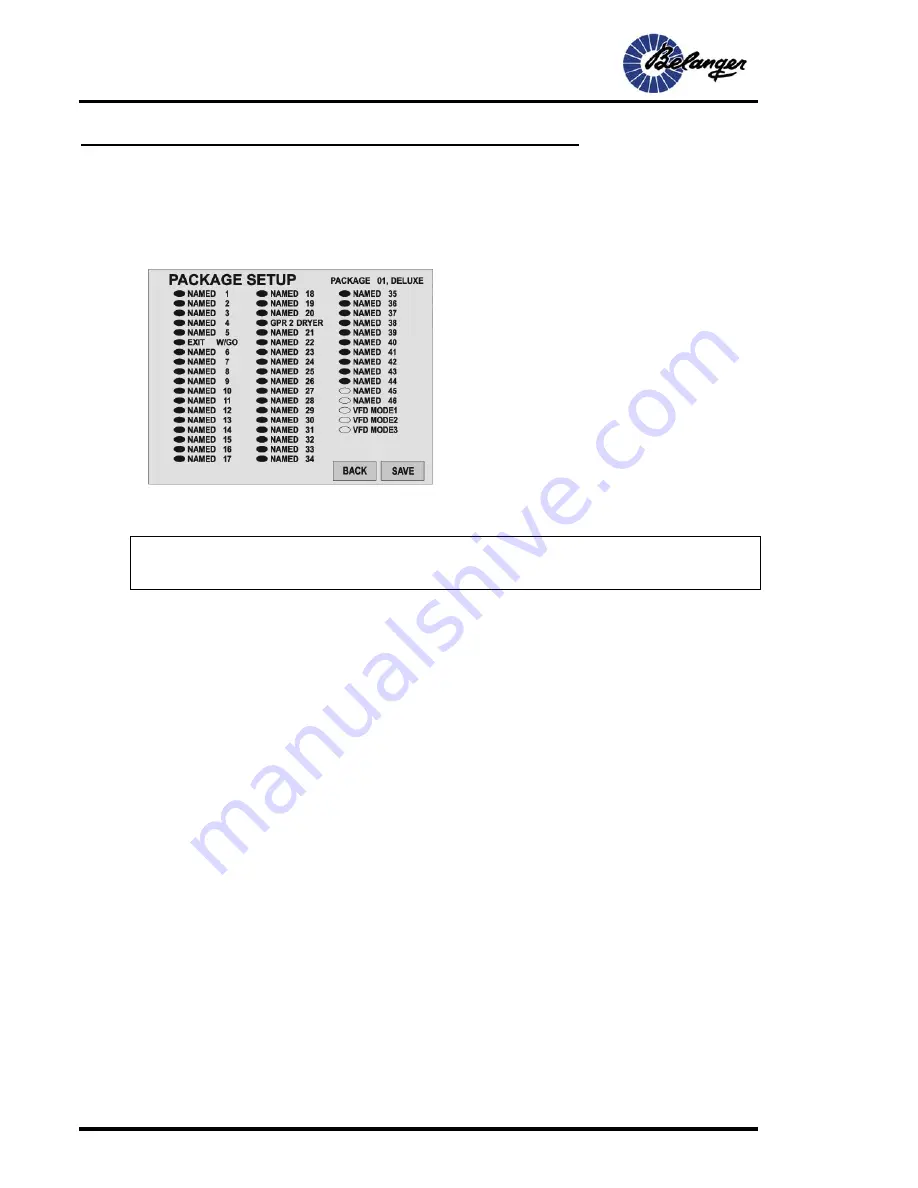

Setup / Packages / Package 1 (or any of the Package buttons)

CHANGES WILL NOT TAKE EFFECT AND WILL BE LOST IF “SAVE” IS NOT SELECTED ONCE SELECTIONS

ARE MADE.

Note:

The names of the Functions may be changed from the names

shown in the above screen.

Screen Key:

•

When an Oval is filled, that item becomes part of the

Package.

•

Touch the desired oval to toggle between filled and

unfilled.

•

See SETUP / FUNCTIONS for configurations of

Functions.

•

VFD Mode 1 – Network VFD Dryer switch to set distance

for Package.

•

VFD Mode 2– Network VFD Dryer switched OFF for

Package.

•

VFD Mode 3– Network Pump 1 selected for Package.

Содержание Signature Series

Страница 2: ......

Страница 4: ......

Страница 7: ...Chapter 1 Introduction Chapter 1 Introduction Chapter REV 01 ...

Страница 8: ......

Страница 13: ...Chapter 2 General Machine Operations Chapter 2 System Overview Chapter REV 01 ...

Страница 14: ......

Страница 21: ...INTEGRA E 1063 1MANUL102 Belanger Inc 1001 Doheny Ct Northville MI 48167 Ph 248 349 7010 Fax 248 380 9681 2 7 ...

Страница 22: ......

Страница 24: ......

Страница 28: ......

Страница 44: ...INTEGRA E 1063 4 16 Belanger Inc 1001 Doheny Ct Northville MI 48167 Ph 248 349 7010 Fax 248 380 9681 1MANUL102 ...

Страница 45: ...Chapter 5 Operator Interface Programming Chapter 5 Operator Interface Wash Setup Screens Chapter REV 01 ...

Страница 46: ......

Страница 69: ...Chapter 6 Techniques in Programming Chapter 6 Techniques in Wash Setup Chapter REV 01 ...

Страница 70: ......

Страница 76: ......

Страница 77: ...Chapter 7 Faults and Alarms Chapter 7 Faults and Alarms Chapter REV 01 ...

Страница 78: ......

Страница 84: ...INTEGRA E 1063 7 6 Belanger Inc 1001 Doheny Ct Northville MI 48167 Ph 248 349 7010 Fax 248 380 9681 1MANUL102 ...

Страница 85: ...Chapter 8 Network and E Mail Application Chapter 8 Network and E Mail Application Chapter REV 01 ...

Страница 86: ......

Страница 91: ...Chapter 9 E 1063 Screen Map Chapter 9 E 1063 Programming Screen Map Chapter REV 01 ...

Страница 92: ......

Страница 93: ......