CLEARPOINT® Flanged L100-L304_us_en_2014-6 (rev. A)

9

INSTALLATION SITE

Serious consideration should be given when selecting the installation site for the filter, as an improper

location could directly affect the proper operation of the filter.

This unit is not suitable for use in explosive atmospheres, where risk of fire could exist, in the presence of

gaseous or solid pollutants or in outdoor applications or areas exposed to the elements.

Don’t use water to extinguish fire on or in the

area surrounding filter installation.

Technicians that service the CLEARPOINT® Flange filter must wear hearing protection while servicing the

filter. Each employee must select a proper personal protection unit (PPD) for hearing protection such as

earmuffs, ear canal caps or earplugs in order to prevent permanent damage or loss of hearing

Minimum Installation Requirements:

Select a clean, dry room that is free of dust and protected from atmospheric disturbances.

Maximum operating pressure of 200 psig

Minimum operating temperature of +35 °F

Maximum operating temperature of +140 °F

Allow a

clearance of at least 3’ on all sides of the

filter in order easily facilitate all maintenance needs.

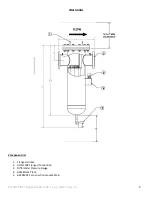

POSITIONING

The housing should be mounted in a vertical position. Observe the direction of flow which is indicated by an arrow on

page 8 of the dimensional drawing, note that this is the standard flow. All reverse flow units will flow from the outside

into the filters.

For replacing the filter elements, it is necessary to leave a handling space of 34 in above the filter.

INSTALLATION

For better filter efficiency, it is recommended to install the unit at a preferably cool, but frost-protected point along the

pipe network.

The separation rate and service life figures assume filtration using pre-filters of the next coarser grade (exception; coarse

filter series C).

Furthermore, it is recommended to install a shutoff valve both on the inlet and the outlet side of the filters or filter

combination. A bypass line with an additional shutoff valve should be installed so that the pipe network can still be

supplied with compressed air during routine maintenance work.