Securing the drive against axial displacement

-10 mm

In order to secure the drive against axial displacement, we recommend screwing the

drive adapter to the tube.

Attention

When drilling into the barrel, never drill near the tubular drive!

Fixing the drive adapter to the barrel dia. 45

Size of drive

[mm]

Diameter of barrel

[mm]

Torque

max. [Nm]

Fastening screws

for drive adapter (4 pc.)

dia. 45

50 - 70 mm plastic drive adapter

25

Self-tapping screw

dia. 4.8 x 9.5 mm

dia. 45

50 - 85 mm plastic drive adapter

for obstacle detection

40

Self-tapping screw

dia. 4.8 x 9.5 mm

dia. 45

50 - 85 mm diecast drive adapter

50

Self-tapping screw

dia. 4.8 x 9.5 mm

We also recommend screwing the idler to the barrel.

Attention

Do not hammer the tubular drive into the tube or drop it into the barrel!

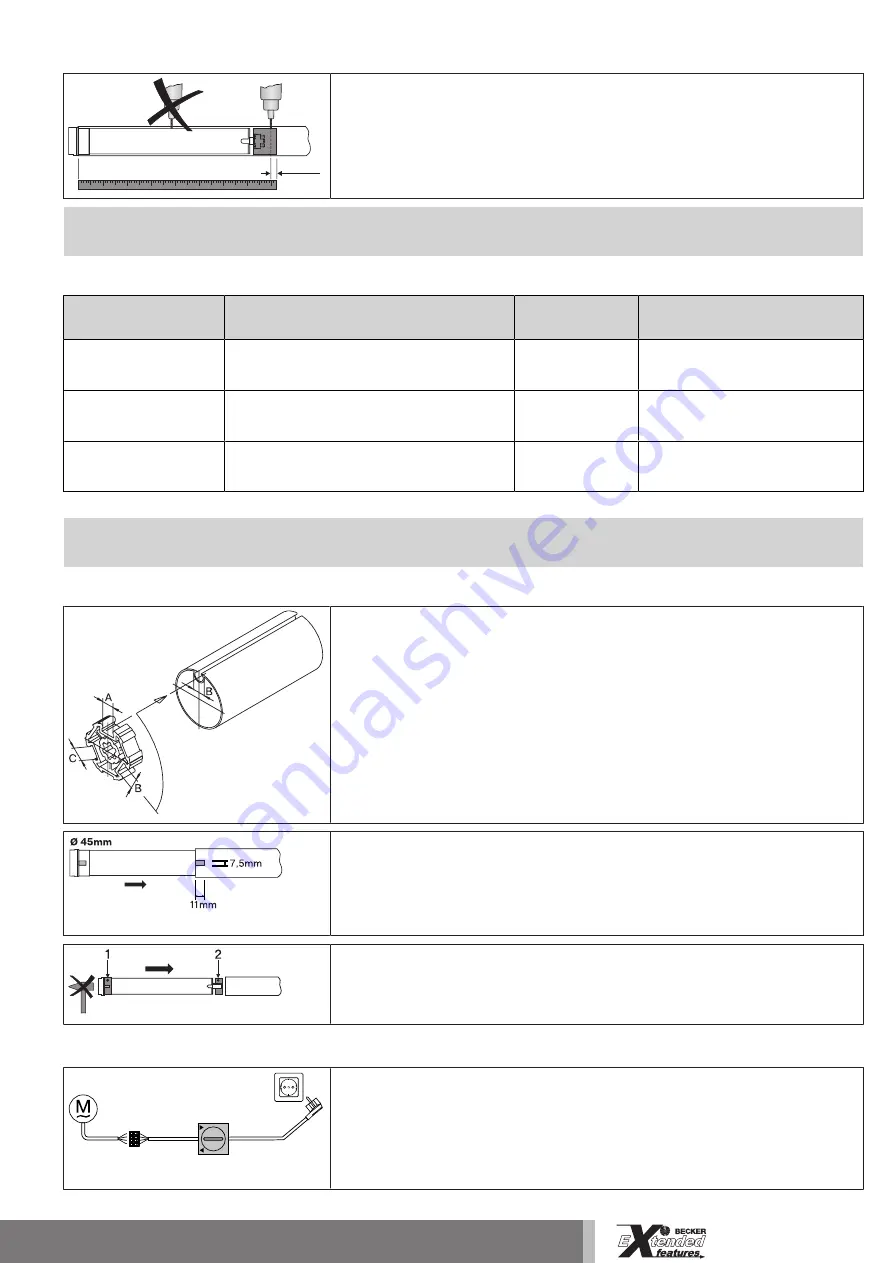

Mounting the drive in the tube

For profile tubes:

In the case of some drive adapters, tolerances of the groove widths in different bar-

rels can be offset by rotating the drive adapter into a different groove recess. These

groove recesses have different sizes and allow the drive to fit exactly.

For round tubes:

First notch the tube on the motor side, so the lug of the thrust ring can also be pushed

into the tube. There must be no play between the lug of the thrust ring and the tube.

For rings without drive lugs, which are used to assist fitting on the thrust ring, the bar-

rel must be connected to the thrust ring by a 4.8 x 9.5 mm self-tapping screw.

Assemble the tubular drive with the relevant thrust ring (1) and drive adapter (2). In-

sert the tubular drive with the pre-assembled thrust ring and drive adapter into the

tube to achieve a form fit. Ensure that the thrust ring and drive adapter are secure in

the tube.

Mount the assembled unit comprising barrel, tubular drive and idler on the box and secure the drive with a split or spring pin ac-

cording to the type of wall bracket fixing.

The drive can be commissioned either with the switch (Item no. 4901 001 158 0) or

the operator control provided.

Connect the pigtail wires of the tubular drive to those of the same colour in the switch

or operator control and switch on the power supply. Check the direction of travel. If

the direction of travel of the shading solution does not correspond to the operator

control, swap the black and brown pigtail wires of the tubular drive.

9

Содержание Extended Features XR7/85

Страница 15: ...Declaration of conformity 15 ...

Страница 16: ......