TAM 00746

14

DSP1 045 - 100

11 / 2019

Three phase synchronous motor

English

subsidiary,

if

required).

In the case of axial forces, clarification with the motor manufacturer is always required.

the brake (optional) can be released after the operating voltage has been applied (audi-

ble switching noise).

the rotor can be rotated evenly and without any streaking noises.

If the motor has an integrated brake, first release the brake.

the design of the motor, encoder and fan lines, if any, comply with the requirements of

the technical documentation for the product.

The output or drive elements are protected.

the complete cooling system is functional and protected against any foreign particles

falling into it.

3.3 Vibrations and vibration resistance

The vibration behavior of the entire system at the place of use, due to output elements, mounting con-

ditions, alignment and installation as well as by influences of external vibrations, can lead to an in-

crease in the vibration values at the motor.

Under certain circumstances it may be necessary to completely balance the rotor with the output ele-

ment.

In order to be able to guarantee perfect function and service life, the vibration values specified in ac-

cordance with DIN ISO 10816 must not be exceeded at the specified measuring points of the motor

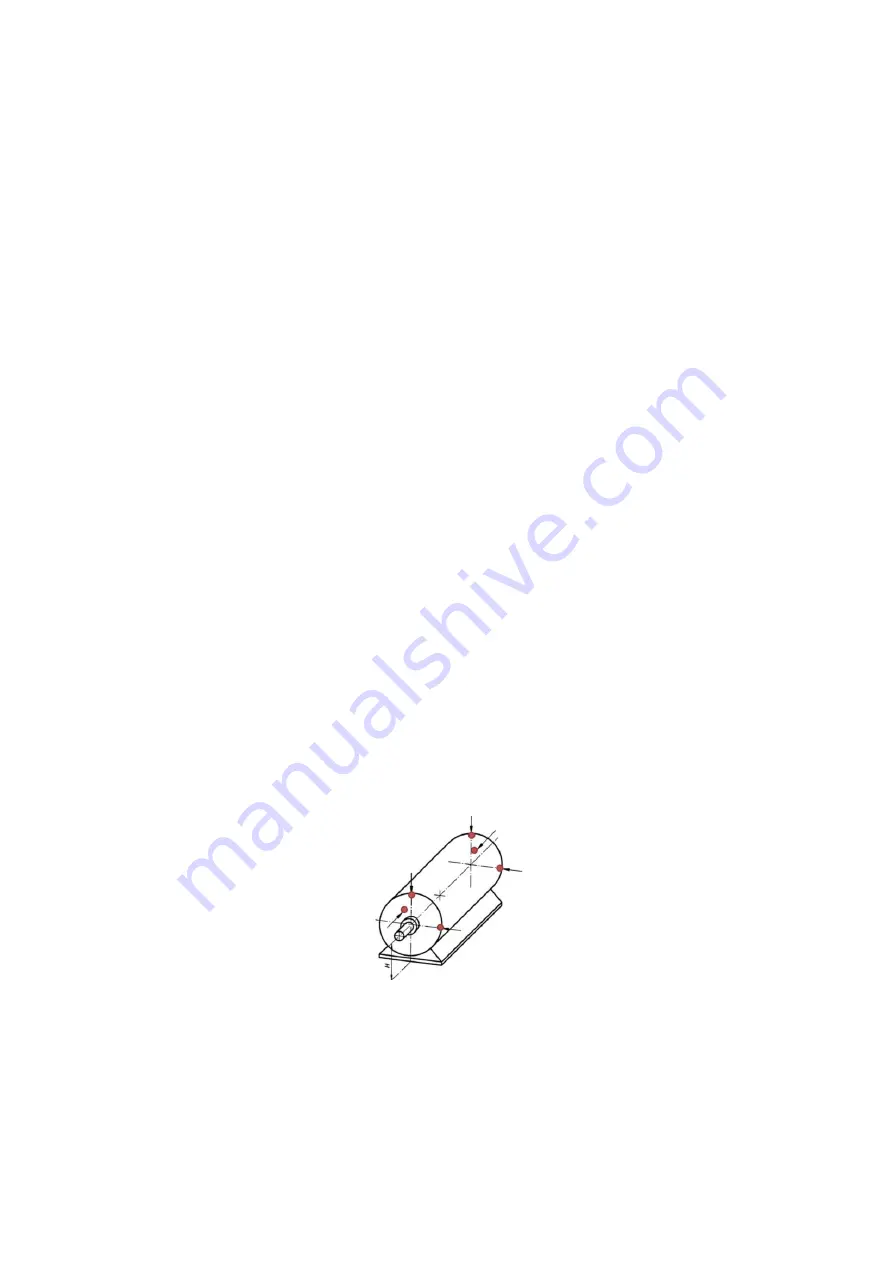

(see Figure 1).

Figure 1: Measuring points for vibration measurement

The specified maximum radial and axial vibration values must be complied to simultaneously. They

apply to substructures that can be described as elastic. An elastic substructure is present if the lowest

natural frequency of the overall system (machine and foundation) in the measuring direction is at least

25% below the essential excitation frequency. All other structures can be described as rigid. In the

case of rigid substructures, the manufacturer must be consulted.