Edition: 11/2007

Technical Instructions

Commissioning and Maintenance Guide

TAM 00 526

Page

12

/ 18

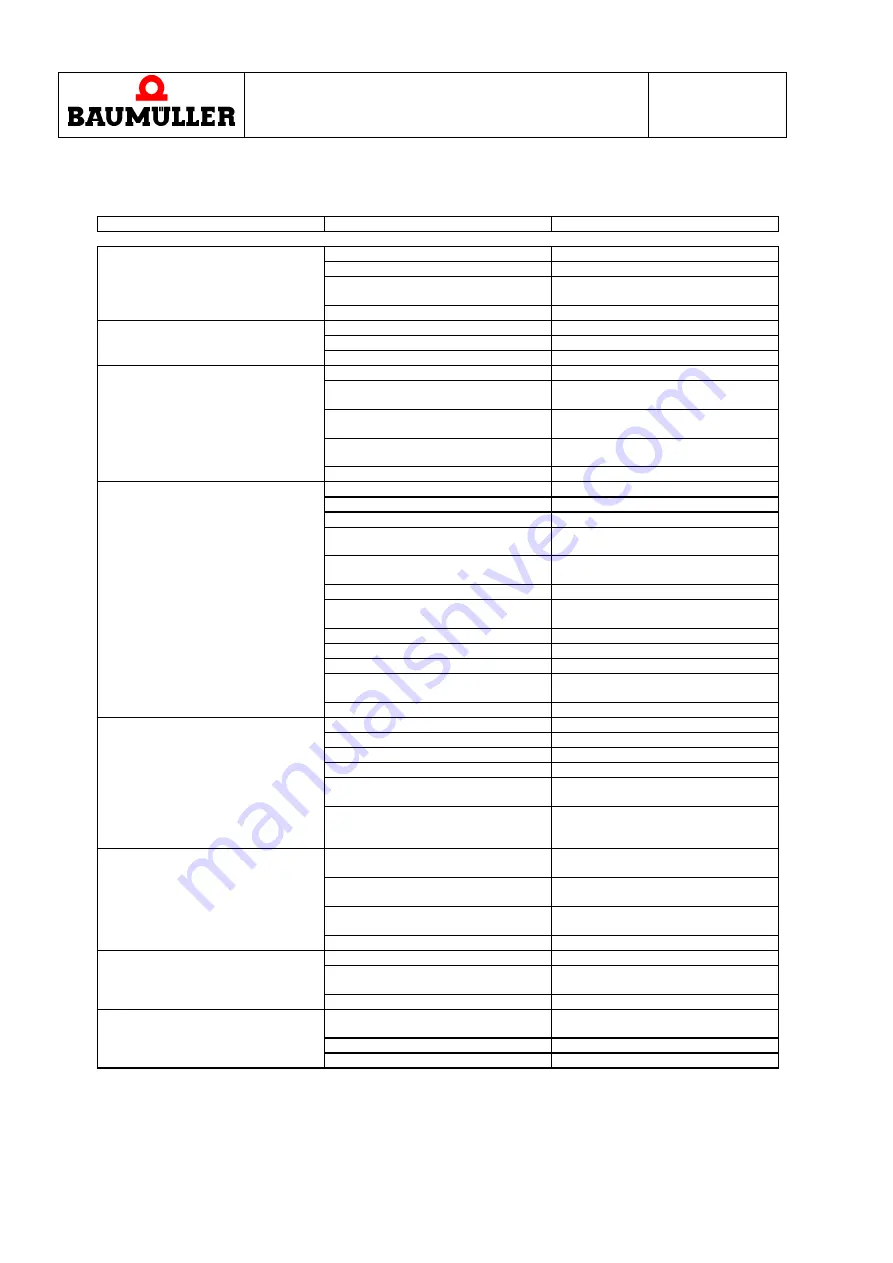

3.5 Operating Disturbances

Error

Possible Cause

Removing the Source of the Error

Motor doesn't start

Supply lead interrupted Check

connections

Setting of brush yoke wrong

Adjust neutral zone

Current limiting doesn't respond

Loading too high or increase current

limiting

Brake doesn't release

Check brake connection

Motor speed drops when under load

Overloading

Carry out performance measurement

Voltage drops

Adjust neutral zone

Setting of brush yoke wrong

Adjust neutral zone

Motor gets too hot

Overloading

Carry out performance measurement

Insufficient cooling

Ensure that the cooling air can enter

without hindrance

Separately driven fan not running

Check connection of separately driven

fan

Current ripple too great

Check form factor, if necessary connect

armature choke on input side

Ambient temperature too high

Reduce performance

Severe brush sparking

Overloading

Carry out performance measurement

Setting of brush yoke wrong

Adjust neutral zone

Commutator surface very dirty

Clean commutator

Commutator out-of-round or with flat

points

Have commutator diameter-turned by

specialists

Lamellar insulation protruding

Have specialists scrape out insulation

grooves and remove sharp edges

Brushes worn out

Insert new brushes

Current ripple too great

Check form factor, if necessary connect

armature choke on input side

Switching error in a section of coil

Have experts carry out checking

Carbon brush sticks in holder

Ensure easy running

Vibrations on the drive

Remove possible unbalance

Unsuitable brush quality

Consult the manufacturer, stating the

technical data and environmental factors

Damage to coil

Get damage removed by specialists

Brush life too short

Current ripple too great

Check form factor

Connect armature choke on input side

Overloading

Carry

out

performance measurement

Current loading of carbon brush too low

Use genuine carbon brushes

Commutator surface affected

Find out the cause (dust, oil fumes, chemi-

cally active gases, etc.) and remove it

Brushes are of different or unsuitable

qualities

Fit the machines with suitable brushes

of consistent quality. Use genuine car-

bon brushes

Motor produces too much noise

Current ripple too great

Check form factor. Connect armature

choke on input side

Bearings warped, dirty or damaged

Realign the motor. Clean and grease the

bearings or replace them

Rotating parts unbalanced

Remove stimulation of vibration and

possible armature unbalance

Current convertor vibrates

Optimize current converter

Speed is unstable

Current convertor not set ideally

Optimize current converter

Large differences in loading

Increase current limiting or use a more

efficient device or motor

Tachometer signal not constant

Check tachometer

Motor accelerates uncontrollably

Error in speed feedback, e.g. tachome-

ter connected wrongly

Connect correct polarity

Tachometer carbon brushes worn-out

Replace carbon brushes

Tachometer lead interrupted

Lay a new tachometer lead