PAGE 39 TP10313

TROUBLESHOOTING - continued

PROBLEM

CAUSE

REMEDY

Sheets fails to re-emerge

Product too thick for folding.

Consult Baum technical rep.

from buckle plate.

Not enough roll pressures.

Check Baumset settings.

Sheet remains lying on

Electrostatic charge in

Fit discharge unit at the

the roller table of the 2nd

product caused by friction

exit to the 1st station

station or fails to run into

with rollers and deflectors

or arrange for appropriate

the 1st buckle plate of the

and also relatively low

humidity on the premises.

2nd folding station.

humidity.

Damping rods and sheet holder

Raise as necessary.

set too low.

Wrinkling after the 1st

Register guide not at right-

Set angle correctly.

fold, either across or

angles to the folding rollers.

parallel.

Sheet drawn too sharply against

Insert fewer balls or use

the register guide causing a wave

lighter ones.

to form.

Buckle plate feed stop not

Correct buckle plate stop

parallel to the incoming sheet

setting.

edge.

Folding rollers set too tight.

Slacken roller setting.

Crooked perforation after

Register guide and buckle

Reset.

1st fold.

plate stop not at right angles

to each other.

Faulty setting of folding

Check and reset as

rollers and slitter shaft.

necessary.

Lower buckle plate lip

Set to zero position.

crooked.

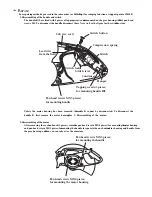

Sheet corners buckled

Sheet deflector set too low.

If the corners are buckled

up or down after the

upwards, set the upper

1st fold.

sheet deflectors back

evenly; if the corners are

buckled downwards, the

lower deflectors must

similarly be set back

evenly by underlaying

pieces of card. In no

circumstances alter the

basic setting of the

deflectors.