7

SPREADING MATERIAL

REGULATING SPREAD QUANTITY

The spreading quantity is adjusted with the tension adjustment lever. Correct adjustment is

important. If the adjustment is too tight, unnecessary wear of the rubber belts or rotating parts may

occur. If the adjustment is too slack, distribution of material will be uneven.

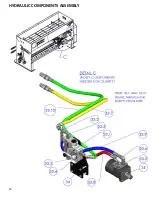

Hydraulic Units:

All hydraulic units are equipped with hydraulic flow control. To ensure to correct

rate of drop of material, the operator would adjust the tension adjustment lever, hydraulic flow

control, engine RPM, and ground speed. Adjusting engine RPM impacts hydraulic flow.

Electric Units:

To ensure the correct rate of drop of material, the operator would adjust the tension

adjustment lever and ground speed. An optional variable power controller may be installed, allowing

for fine-tuning of the motor rotation speed.

STARTING TO SPREAD

Spreading of material star

ts as soon as the tractor’s PTO, hydraulic

, or electrical system is engaged.

HYDRAULIC/ELECTRICAL ROUTING INSTRUCTIONS

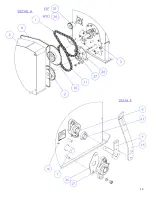

Electrical:

Bauman Manufacturing electric Drop Spreaders include a wiring kit (see page 15 for

schematic). It is the responsibility of the operator to ensure that the motor is wired correctly. It is

important that the direction the distributor drum rotates matches the rotation arrow in

Figure A

. A

decal depicting the correct rotation direction has also been positioned near the bearings supporting

these shafts.

Hydraulic:

Similarly, the hydraulic spreader models come equipped with the hoses and fittings

already installed in their intended orientation. Ensure the tractor hoses are attached in such a way

that allows for the agitator and distributor drum to rotate in the direction shown in Figure A.

Figure A:

Direction of Drum

Rotation

Содержание 440E

Страница 1: ...BAUMAN MANUFACTURING 440E 440H DROP SPREADER OPERATOR S MANUAL...

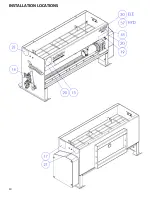

Страница 12: ...10 INSTALLATION LOCATIONS...

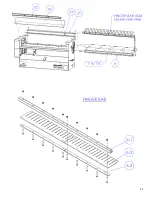

Страница 13: ...11...

Страница 14: ...12...

Страница 15: ...13...

Страница 16: ...14 HYDRAULIC COMPONENTS ASSEMBLY...

Страница 17: ...15 ELECTRICAL HOOK UP DIAGRAM...

Страница 21: ...19 NOTES...

Страница 22: ...20...

Страница 23: ...21...

Страница 24: ...22...