12

10

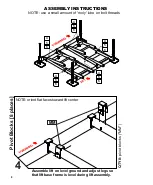

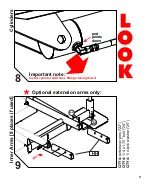

NOTE: use a small amount of 'moly' lube on bolt threads

ASSEMBLY INSTRUCTIONS

12

12

10

10

12

12

10

10

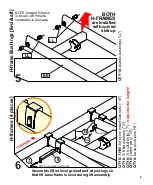

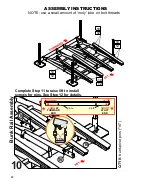

Complete Step 11 to raise lift to install

screws for pins. See Step 12 for details.

16

16

KK

JJ

16

16

B

u

n

k

R

a

il

A

s

s

e

m

b

ly

Q

T

Y

8

:

b

u

n

k

p

iv

o

t

p

in

s

("

1

6

")

13

Power unit

NOTE: always turn unit OFF when not in use

11

CONNECT POWER UNIT

6.

Test the lift on dry ground using the Up/Down Switch

and the Key Fob Transmitters. Inspect the system

for leaks.

1.

The Hydraulic Power Unit will arrive fully assembled.

Make sure all the connections are snug to prevent

leaks or loss of power to the unit.

Install a Group 31 Deep Discharge AGM Battery as

shown above. Be sure to connect the Red Battery

Cable to the p ositive terminal and the Black Battery

Cable to the negative terminal.

NOTE:

Ensure battery cables are correctly connected

3.

Slide the Hydraulic Hose Assembly through the

access hole in the side of the fiberglass Enclosure

and attach the ends to their corresponding

Quick Couplers.

and their terminals are tight (use a wrench).

one

inch

only add fluid with lift

in DOWN position

Ensure each Quick Coupler is

completely seated and

tight

with

no gap at the connection joint.

Connection must be

tight

to open internal

check valve and allow fluid to flow. USE PLIERS

DO NOT SUBMERSE

Keep inside dry

4. Plug the cable from the Solar Panel into the connector

on the wiring harness that comes from the Remote

Control Unit as shown in the picture on Page 14.

NO GAP!

Prevent unauthorized use -

KEEP BOX LOCKED

hydraulic fluid level shown

with lift in DOWN position

2.

COMPLETE POWER UNIT

#

H653-0001

power

switch

POSITIVE BATTERY

CABLE (RED)

#

R711-1010

NEGATIVE BATTERY

CABLE (BLACK)

#

R711-1005

HOSE ASSEMBLIES

#

H123-0001

remote

receivers

up/down

switches

MALE QUICK COUPLER

#

H770-0002

FEMALE QUICK COUPLER

#

H770-0001

5.

Read Operating Instructions on Page 17.

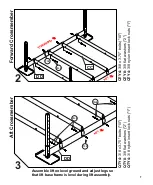

SHORT

AT AFT

END

LONG

AT

FORWARD

END

plate

plate

pre-installed

bushings are