5-4

TESTS AND ADJUSTMENTS

NOTE

Steps 7 and 8 apply only to overvoltage functions.

NOTE

Step 8 applies only to Relay Model BE1-59 with Sensing Input Range 3 or 4.

326.4 for Sensing Input Range 4.

This concludes the pickup test for Relay Model BE1-27.

Step 7. Slowly increase the T1 voltage until the OVER PICKUP indicator and the timed and instantaneous

overvoltage test indicators illuminate. Measure and record the voltage.

RESULT: This voltage is between 156.8 and 163.2 Vac for Sensing Input Range 3 or between 313.6 and

326.4 Vac for Sensing Input Range 4.

Step 8.

Decrease the T1 voltage to 50 Vac . Turn all overvoltage pickup controls fully CCW. Slowly

increase the T1 voltage until the OVER PICKUP indicator and the timed and instantaneous

overvoltage test indicators illuminate. Measure and record the voltage.

RESULT: The voltage is between 53.9 and 56.1 Vac for Sensing Input Range 3 or between 107.8 and

112.2 Vac for Sensing Input Range 4.

This concludes the pickup test.

Timing

The following procedure verifies timing characteristics.

Step 1.

Connect the test circuit shown in Figure 5-2. Output terminal connections are dependent on the

function to be tested. (See Table 5-1.)

Step 2. Adjust the under or overvoltage pickup settings and the T1 and T2 tap voltage levels as indicated

below for the function being tested.

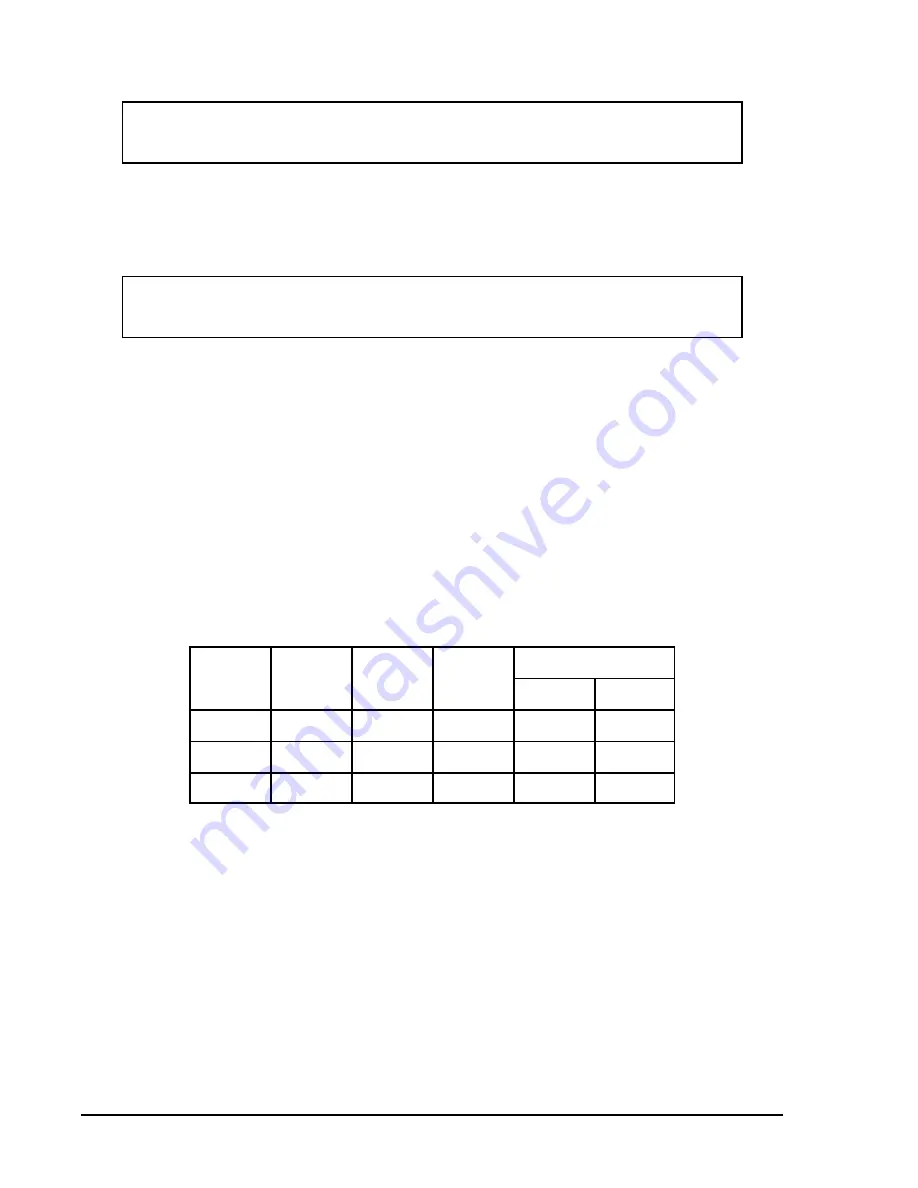

Sensing

Over Under T1

T2

Range

Pickup

Pickup

Voltage

Over

Under

2

30

—

20

40

—

3

120

100

110

152

68

4

240

200

220

304

136

Step 3.

Set the time delay control for the function being tested to 0.1. Press and release S2 to assure

that K1 is de-energized. Reset the timer. Press and release S1.

RESULT: The timer displays a response time, dependent on timing type, as indicated in Column 1 of

Table 5-2.

Step 4.

Press and release S2. Set the time delay control for the function being tested to 99. Reset the

timer. Press and release S1.

RESULT: The timer displays a response time, dependent on timing type, as indicated in Column 2 of

Table 5-2.

Step 5.

Repeat Steps 9 through 13 as necessary for each function's time delay control.

This concludes the operational test procedure.

Содержание BE1-27

Страница 21: ...INSTALLATION 4 3 Figure 4 2 S1 Case Single Ended Semi Flush Mounting Outline Dimensions Side View...

Страница 22: ...4 4 INSTALLATION Figure 4 3 S1 Case Single Ended Projection Mount Outline Dimensions Side View...

Страница 23: ...INSTALLATION 4 5 Figure 4 4 S1 Case Double Ended Semi Flush Mounting Outline Dimensions Side View...

Страница 24: ...4 6 INSTALLATION Figure 4 5 S1 Case Double Ended Projection Mount Outline Dimensions Side View...

Страница 25: ...INSTALLATION 4 7 Figure 4 6 S1 Case Single Ended Semi Flush Mounting Outline Dimensions Rear View...

Страница 26: ...4 8 INSTALLATION Figure 4 7 S1 Case Single Ended Projection Mount Outline Dimensions Rear View...

Страница 27: ...INSTALLATION 4 9 Figure 4 8 S1 Case Double Ended Semi Flush Mounting Outline Dimensions Rear View...

Страница 28: ...4 10 INSTALLATION Figure 4 9 S1 Case Double Ended Projection Mount Outline Dimensions Rear View...

Страница 29: ...INSTALLATION 4 11 Figure 4 10 S1 Case Panel Drilling Diagram Semi Flush Mounting...

Страница 30: ...4 12 INSTALLATION Figure 4 11 S1 Case Single Ended Projection Mount Panel Drilling Diagram Rear View...

Страница 31: ...INSTALLATION 4 13 Figure 4 12 S1 Case Double Ended Projection Mounting Panel Drilling Diagram Rear View...

Страница 32: ...4 14 INSTALLATION Figure 4 13 BE1 27 Internal Connections...

Страница 33: ...INSTALLATION 4 15 Figure 4 14 BE1 59 Internal Connections...

Страница 34: ...4 16 INSTALLATION Figure 4 15 BE1 27 59 Internal Connections...

Страница 35: ...INSTALLATION 4 17 BE1 27 BE1 59 BE1 27 59 6 D2816 13 05 29 98 7 52 A B C Figure 4 16 Typical AC Connections...