48

Barnstead International (“BARNSTEAD”) warrants that if a product manufactured by Barnstead shall be free

of defects in materials and workmanship for two (2) years from the first to occur of (i) the date the product is

sold by BARNSTEAD or (ii) the date the product is purchased by the original retail customer (the

“Commencement Date”). Except as expressly stated above, BARNSTEAD MAKES NO OTHER WARRANTY,

EXPRESSED OR IMPLIED, WITH RESPECT TO THE PRODUCTS AND EXPRESSLY DISCLAIMS ANY

AND ALL WARRANTIES, INCLUDING BUT NOT LIMITED TO, WARRANTIES OF DESIGN, MERCHANT

ABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

An authorized representative of BARNSTEAD must perform all warranty inspections. In the event of a defect

covered by BARNSTEAD’s warranty, BARNSTEAD shall, as its sole obligation and exclusive remedy, provide

free replacement parts to remedy the defective product. In addition, for products sold by BARNSTEAD within

the continental United States or Canada, BARNSTEAD shall provide provide free labor to repair the products

with the replacement parts, but only for a period of ninety (90) days from the Commencement Date.

BARNSTEAD’s warranty provided hereunder shall be null and void and without further force or effect if there

is any (i) repair made to the product by a party other than BARNSTEAD or its duly authorized service repre-

sentative, (ii) misuse (including use inconsistent with written operating instructions for the product), mishan-

dling, contamination, overheating, modification or alteration of the product by any customer or third party or

(iii) use of replacement parts that are obtained from a party who is not an authorized dealer of BARNSTEAD.

Heating elements, because of their susceptibility to overheating and contamination, must be returned to the

BARNSTEAD factory and if, upon inspection, it is concluded that failure is due to factors other than excessive

high temperature or contamination, BARNSTEAD will provide warranty replacement. As a condition to the

return of any product, or any constituent part thereof, to BARNSTEAD’s factory, it shall be sent prepaid and a

prior written authorization from BARNSTEAD assigning a Return Materials Number to the product or part shall

be obtained.

IN NO EVENT SHALL BARNSTEAD BE LIABLE TO ANY PARTY FOR ANY DIRECT, INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES, OR FOR ANY DAMAGES RESULTING FROM LOSS OF

USE OR PROFITS, ANTICIPATED OR OTHERWISE, ARISING OUT OF OR IN CONNECTION WITH THE

SALE, USE OR PERFORMANCE OF ANY PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CON-

TRACT, TORT (INCLUDING NEGLIGENCE), ANY THEORY OF STRICT LIABILITY OR REGULATORY

ACTION.

The name of the authorized Barnstead International dealer nearest you may be obtained by calling

1-800-446-6060 (563-556-2241) or writing to:

2555 Kerper Boulevard

Dubuque, Iowa 52001-9918

Phone: 563-556-2241 or 800-553-0039

Fax: 563-589-0516

E-mail: [email protected]

www.barnstead.com

Two Year Limited Warranty

Содержание SUPER-NUOVA HP133420-33

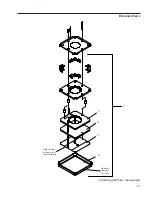

Страница 36: ...36 Exploded Views 6 5 7 8 9 10 11 22 13 14 12 16 15 2 1 3 4 7x7 Stirring Hot Plate Exploded View...

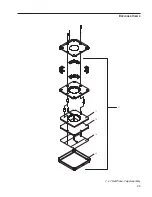

Страница 38: ...38 EXPLODED VIEWS 7 x 7 Hot Plate Exploded View 5 6 7 8 10 22 12 13 16 1 2 3 4...

Страница 39: ...39 EXPLODED VIEWS 21 17 18 19 20 7 x 7 Hot Plate Top Assembly...

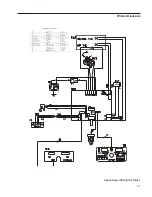

Страница 45: ...45...

Страница 46: ...46...

Страница 47: ...47...