4

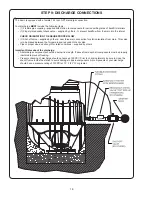

GENERAL INFORMATION

- In general, your home

wastewater disposal service is part of a larger low-

pressure sewer system. The key element in this

system is the Barnes grinder station. The station

collects all wastewater from your house or facility.

The solids in the sewage are then ground into a

small size by the grinder pump within your station,

suitable for pumping in the system. The grinder

pump generates suffi cient pressure to pump the

slurry created from your home to the wastewater

treatment plant.

With proper care and by following a few simple

guidelines, your station will give you many years

of dependable service. The station is designed to

handle routine, domestic and light industrial sewage.

Solid waste materials should be thrown in the trash.

A preventative maintenance schedule should be

developed to further increase the longevity of your

station.

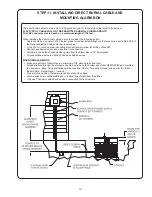

RECOMMENDED PREVENTATIVE MAINTENANCE

Annually:

• Visually inspect the power cables, control

harnesses and rope. Make sure they are

properly hung on the adapter hooks and

free from defects.

• Check operation of the visual alarm lamp

and audible siren in the alarm box

• Make sure alarm box is free from any

moisture.

• After inspection, make sure alarm box

cover and system rock cover are secure

and locked.

If Alarm Sounds:

• Contact your local authorized service

representative or the local municipality

and have them inspect and/or trouble

shoot your system.

Regulatory agencies advise that the following items

SHOULD NOT BE

introduced into any sewer either

directly or through a drain or waste disposal:

•

Glass, metal, or plastic

•

Diapers, Sanitary napkins, or tampons

•

Socks, rags, or cloth

In addition, you must

NEVER

introduce into any

sewer:

•

Explosives or Flammable material

•

Lubricating oils or Grease

•

Strong Chemicals or Gasoline

POWER FAILURE

– Your grinder pump station

cannot dispose of wastewater or provide an alarm

signal without electrical power. If an electrical out-

age occurs, keep your water usage to a minimum.

Your station has reserve capacity available to help

avoid alarm or high-level occurrences during power

outages.

STATION START-UP/WARRANTY REGISTRATION

A start-up/warranty registration form is included in the

back of this manual. It must be properly completed

and sent to the factory for review before a warranty

can be activated. Invalid or missing data or failure

to return the form will delay or void warranty. If you

feel you have a claim under the provisions of your

warranty, please contact your local Crane Pumps

& Systems, Inc. Distributor. Please be sure to have

your station part number and model number along

with the pump part number and model number.

YOU SHOULD READ THIS MANUAL

CAREFULLY BEFORE BEGINNING YOUR

INSTALLATION!

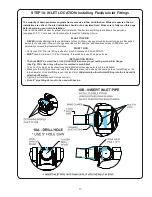

Various references to ballasting, proper backfi ll

procedures, and other steps required to properly

install your new basin package are located throughout

the manual. You should understand these aspects

to avoid installation issues. If you have questions

or concerns regarding your particular installation,

contact your local Barnes representative or contact

the factory at (937) 778-8947.

For future reference, record the following information:

Station Serial No:

Pump Model No:

Pump Serial No:

Local Distributor:

Distributor Telephone:

USER GUIDE

Содержание EcoTRAN

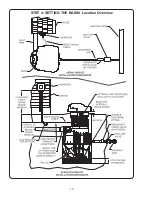

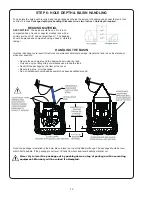

Страница 10: ...10 STEP 4 SETTING THE BASIN Location Overview...

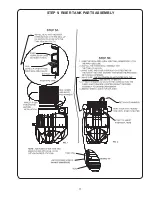

Страница 11: ...11 STEP 5 RISER TANK PARTS ASSEMBLY...

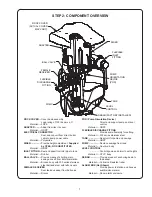

Страница 30: ...30 11 23 13 12 29 4 15 16 18 17 6 5 7 26 25 32 9 8 2 1 31 17...

Страница 36: ...Notes...