9

F-2) Impeller and Volute Service:

F-2.1) Disassembly and Inspection:

To clean out volute (24) or replace impeller (29), disconnect

power, remove screws (12), and lockwashers (11), vertically

lift motor and seal plate assembly from volute (24). Clean

out volute if necessary. Clean and examine impeller (29), for

pitting or wear and replace if required, inspect gasket (10)

and replace if cut or damaged. If the impeller (29) needs

replacing, remove nut (3), place a fl at screwdriver in the

slot of the end of the shaft to hold the shaft stationary while

unscrewing the impeller (29). (See Figure 11 or 12)

F-2.2) Reassembly:

To install impeller (29), screw impeller onto the shaft hand tight.

Clean the threads with Loctite cleaner. Apply thread locking

compound to shaft threads and install nut (3). Torque to 40

ft. lbs. Rotate impeller to check for binding. Position gasket

(10) on volute fl ange and position impeller and motor housing

on volute (24). Position lockwashers (11) on cap screws (12)

and screw into volute (24). Torque to 8 ft. lbs. Check for free

rotation of motor and impeller. (See Figure 11 or 12)

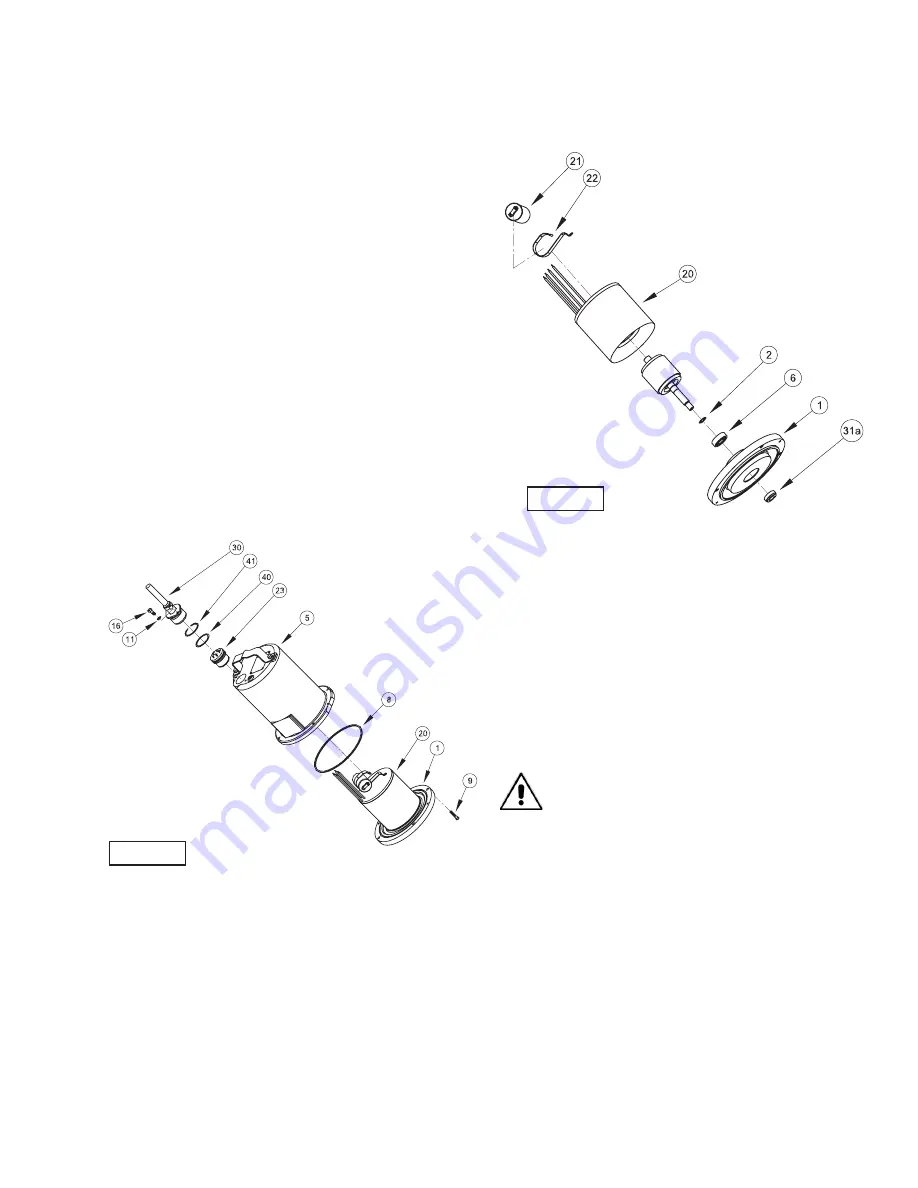

F-3) Motor and Bearing Service:

F-3.1) Disassembly and Inspection:

To examine or replace the motor (20), capacitor (21, single

phase units), and bearing (6), drain oil from motor as outlined

in paragraph F-1.2. Disassemble volute and impeller as

outlined in paragraph F-2.1 and disassemble shaft seal as

outlined in paragraph F-4.1. (See Figure 3, 4, and 11)

Position unit upright, using blocks to avoid resting unit on

shaft. Unscrew cable hex bolts (16) and remove compression

fl ange (30a) and power cord (30). Remove snap ring (41) with

a fl at head screwdriver. Pull the terminal block (23) out of the

housing (5) using a T-bolt or pair of pliers and a 1/4”-20 screw

in the threads of the terminal block (23). Be sure to leave

slack on the motor leads connected underneath. Use needle

nose pliers to pull each female connector off of the pins on

the underside of the terminal block (23) (see Figure 5). The

unit voltage should be noted. Repeat cable and terminal block

removal procedure for any control cables (32) if equipped.

Remove socket head cap screws (9). Vertically lift the motor

housing (5) from seal plate (1) by lifting handle (17). Inspect

square ring (8) for damage or cuts. Remove the motor bolts

and lift motor stator from seal plate (1). Disconnect capacitor

leads from capacitor (21, single phase units). Examine

bearing (6) and replace if required. If replacement is required,

remove bearing (6) from motor shaft using a wheel puller or

arbor press, see Figure 4.

Check motor capacitor (21, single phase units) with an

Ohm meter by fi rst grounding the capacitor by placing

a screwdriver across both terminals and then removing

screwdriver. Connect Ohm meter (set on high scale) to

terminals. If needle moves to infi nity (∞) then drifts back,

the capacitor is good. If needle does not move or moves to

infi nity (∞) and does not drift back, replace capacitor (21).

To test the temperature sensor (P1 / P2, optional), check for

continuity between the wire leads (see Figure 10). If found

to be defective, contact a motor service station or Barnes

Pumps Service department. Inspect motor winding for shorts

and check resistance values. Check rotor for wear. If rotor or

the stator windings are defective, the complete motor must be

replaced.

IMPORTANT! - All parts must be clean before

reassembly.

F-3.2) Reassembly:

Bearing - When replacing bearing, be careful not to damage

the rotor or shaft threads. Clean the shaft thoroughly. Apply

adhesive compound to the shaft and press bearing (6) on the

motor shaft, position squarely onto the shaft applying force to

the inner race of the bearing only, until bearing seats against

the retaining ring (2).

FIGURE 4

FIGURE 3