8

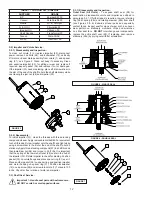

MODEL

NO

PART

NO

HP VOLT/PH Hz RPM

(Nom)

NEMA

START

CODE

INSUL.

CLASS

FULL

LOAD

AMPS

LOCKED

ROTOR

AMPS

CORD

SIZE

CORD

TYPE

CORD

O.D

inch (mm)

WINDING RESISTANCE

Emerson

Main-Start

Franklin

Main-Start

G.E.

Main-Start

2SEV514L

104918 0.5

120/1

60 1750

F

B

12.0

21.3

14/3 SJTOW

0.375 (9.5)

1.51-16.10

2SEV524L

104919 0.5

240/1

60 1750

J

B

6.3

14.9

14/3

SOW

0.530 (13.5)

3.38-9.30

5.69-18.74

2SEV594L

104920 0.5 200-240/3 60 1750

H/L

B

3.7/3.8 9.8/11.0

14/4

SOW

0.570 (14.5)

10.20

13.00

2SEV544L

104921 0.5

480/3

60 1750

K

B

1.9

5.3

14/4

SOW

0.570 (14.5)

40.80

52.00

2SEV554L

104922 0.5

600/3

60 1750

H

B

1.4

3.4

14/4

SOW

0.570 (14.5)

77.60

89.76

2SEV724L

104928 0.75

240/1

60 1750

K

F

7.1

25.8

14/3

SOW

0.530 (13.5)

1.86-10.20

2.74-10.56

2SEV794L

104929 0.75 200-240/3 60 1750

H/K

F

4.8/4.6 13.7/15.4

14/4

SOW

0.570 (14.5)

5.49

6.28

2SEV744L

104930 0.75

480/3

60 1750

K

F

2.3

7.7

14/4

SOW

0.570 (14.5)

21.96

24.51

2SEV754L

104931 0.75

600/3

60 1750

L

B

1.6

7.2

14/4

SOW

0.570 (14.5)

34.36

36.60

2SEV1024L

104936 1.0

240/1

60 1750

G

F

8.5

25.8

14/3

SOW

0.530 (13.5)

1.86-10.20

2.74-10.56

2SEV1094L

104937 1.0 200-240/3 60 1750

E/H

F

5.3/5.1 13.7/15.4

14/3

SOW

0.570 (14.5)

5.49

6.28

2SEV1044L

104938 1.0

480/3

60 1750

H

F

2.5

7.7

14/4

SOW

0.570 (14.5)

21.96

24.51

2SEV1054L

104939 1.0

600/3

60 1750

J

B

2.2

7.2

14/4

SOW

0.570 (14.5)

34.36

36.60

2SEV512L*

104970 0.5

120/1

60 3450

G

B

12.6

24.6

14/3 SJTOW

0.375 (9.5)

1.04-7.20

1.47-9.59

2SEV522L

104971 0.5

240/1

60 3450

E

B

6.0

10.2

14/3

SOW

0.530 (13.5)

5.08-9.00 10.10-10.16

2SEV592L

104972 0.5 200-240/3 60 3450

P/R

B

5.8/5.3 19.9/18.4

14/4

SOW

0.570 (14.5)

5.50

6.30

2SEV542L

104974 0.5

480/3

60 3450

R

B

2.6

9.1

14/4

SOW

0.570 (14.5)

22.00

25.18

2SEV552L

104975 0.5

600/3

60 3450

T

B

2.1

8.7

14/4

SOW

0.570 (14.5)

21.20

34.57

2SEV1022L

104982 1.0

240/1

60 3450

F

B

10.7

21.8

14/3

SOW

0.530 (13.5)

2.37-6.44 3.04-15.49

2SEV1092L

104983 1.0 200-240/3 60 3450

H/J

B

7.9/7.5 19.9/18.4

14/3

SOW

0.570 (14.5)

5.50

6.30

2SEV1042L

104985 1.0

480/3

60 3450

J

B

3.7

9.1

14/4

SOW

0.570 (14.5)

22.00

25.18

2SEV1052L

104986 1.0

600/3

60 3450

L

B

2.9

8.7

14/4

SOW

0.570 (14.5)

21.20

34.57

2SEV514DS

104923 0.5

120/1

60 1750

F

B

12.0

21.3

14/3 SJTOW

0.375 (9.5)

1.51-16.10

2SEV524DS

104924 0.5

240/1

60 1750

J

B

6.3

14.9

14/3

SOW

0.530 (13.5)

3.38-9.30

5.69-18.74

2SEV594DS

104925 0.5 200-240/3 60 1750

H/L

B

3.7/3.8 9.8/11.0

14/4

SOW

0.570 (14.5)

10.20

13.00

2SEV544DS

104926 0.5

480/3

60 1750

K

B

1.9

5.3

14/4

SOW

0.570 (14.5)

40.80

52.00

2SEV554DS

104927 0.5

600/3

60 1750

H

B

1.4

3.4

14/4

SOW

0.570 (14.5)

77.60

89.76

2SEV724DS

104932 0.75

240/1

60 1750

K

F

7.1

25.8

14/3

SOW

0.530 (13.5)

1.86-10.20

2.74-10.56

2SEV794DS

104933 0.75 200-240/3 60 1750

H/K

F

4.8/4.6 13.7/15.4

14/4

SOW

0.570 (14.5)

5.49

6.28

2SEV744DS

104934 0.75

480/3

60 1750

K

F

2.3

7.7

14/4

SOW

0.570 (14.5)

21.96

24.51

2SEV754DS

104935 0.75

600/3

60 1750

L

F

1.6

7.2

14/4

SOW

0.570 (14.5)

34.36

36.60

2SEV1024DS 104940 1.0

240/1

60 1750

G

F

8.5

25.8

14/3

SOW

0.530 (13.5)

1.86-10.20

2.74-10.56

2SEV1094DS 104941 1.0 200-240/3 60 1750

E/H

B

5.3/5.1 13.7/15.4

14/3

SOW

0.570 (14.5)

5.49

6.28

2SEV1044DS 104942 1.0

480/3

60 1750

H

B

2.5

7.7

14/4

SOW

0.570 (14.5)

21.96

24.51

2SEV1054DS 104943 1.0

600/3

60 1750

J

B

2.2

7.2

14/4

SOW

0.570 (14.5)

34.36

36.60

2SEV512DS* 104976 0.5

120/1

60 3450

G

B

12.6

24.6

14/3 SJTOW

0.375 (9.5)

1.04-7.20

1.47-9.59

2SEV522DS

104977 0.5

240/1

60 3450

E

B

6.0

10.2

14/3

SOW

0.530 (13.5)

5.08-9.00 10.10-10.16

2SEV592DS

104978 0.5 200/240/3 60 3450

P/R

B

5.8/5.3 19.9/18.4

14/3

SOW

0.570 (14.5)

5.50

6.30

2SEV542DS

104980 0.5

480/3

60 3450

R

B

2.6

9.1

14/3

SOW

0.570 (14.5)

22.00

25.18

2SEV552DS

104981 0.5

600/3

60 3450

T

B

2.1

8.7

14/3

SOW

0.570 (14.5)

21.20

34.57

2SEV1022DS 104987 1.0

240/1

60 3450

F

B

10.7

21.8

14/3

SOW

0.530 (13.5)

2.37-6.44 3.04-15.49

2SEV1092DS 104988 1.0 200-240/3 60 3450

H/J

B

7.9/7.5 19.9/18.4

14/4

SOW

0.570 (14.5)

5.50

6.30

2SEV1042DS 104990 1.0

480/3

60 3450

J

B

3.7

9.1

14/4

SOW

0.570 (14.5)

22.00

25.18

2SEV1052DS 104991 1.0

600/3

60 3450

L

B

2.9

8.7

14/4

SOW

0.570 (14.5)

21.20

34.57

OPTIONAL - Temperature sensor cord for 3 phase models is 14/3 SOW, 0.530 (13.5mm) O.D.

OPTIONAL - Moisture sensor cord is 18/5 SOW, 0.470 (11.9mm) O.D.

OPTIONAL - Moisture & Temperature sensor cord for 3 phase models is 18/5 SOW, 0.470 (11.9mm) O.D.

(*) Pump is CSA listed

ONLY.

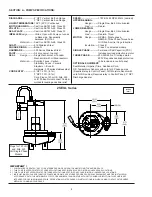

Содержание 2SEV-DS Series

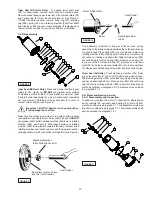

Страница 16: ...16 FIGURE 15 CONTIUED...

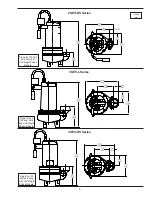

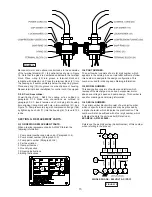

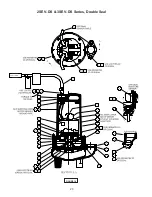

Страница 18: ...18 FIGURE 16 2SEV L 3SEV L Series Single Seal...

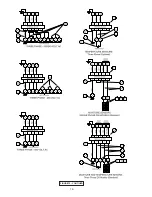

Страница 19: ...19 FIGURE 17 2SEV L 3SEV L Series Single Seal...

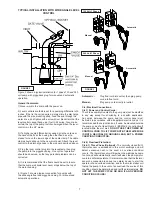

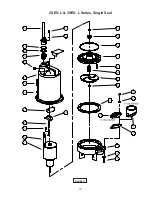

Страница 20: ...20 FIGURE 18 2SEV DS 3SEV DS Series Double Seal...

Страница 21: ...21 FIGURE 19 2SEV DS 3SEV DS Series Double Seal...

Страница 25: ...25 Notes...

Страница 26: ...26 Notes...