3

Recommendations, Warnings & Installation

4

Receiving inspection

Upon receiving the pump, it should

be inspected for damage or

shortages. If damage has occurred,

file a claim immediately with the

company that delivered the pump. If

the manual is removed from the

packaging, do not lose or misplace.

4

Storage

Any product that is stored for a

period longer than six (6) months

from the date of purchase should be

bench tested prior to installation. A

bench test consists of, checking the

impeller to assure it is free turning

and a run test to assure the motor

(and switch if provided) operate

properly. Do not pump out of liquid.

4

Controls

Be sure the electrical specification of

the control selected properly match

the electrical specifications of the

pump.

4

Installation

Location

- The pump should be

located as near as possible to the

liquid to be pumped and in no case

should the pump be more than 25

feet above the surface of the liquid

supply. The pump should always be

as level as possible.

Allow a minimum of 18 inches in

front of the pump case cover or

hatch cover to permit easy removal

and access to the interior of the

pump. On belt driven units, allow a

minimum of 10 inches at the shaft

end to permit easy removal of the

pedestal or rotating cartridge.

Locate the pump on a firm footing to

make sure the pump will not move

due to vibration. Flex coupled and V-

belt

driven

units

should

be

permanently grouted onto a cement

foundation. The pumps should be

level to provide favorable operating

conditions. In addition, the flexible

coupling should be realigned after

grouting in order to eliminate

excessive wear on the coupling.

The use of pipe the same size as the

port size is highly recommended.

Using a smaller pipe line can cause

internal damage. Make sure all lines

have air-tight joints. The smallest air

leak in the suction line may prevent

the

pump

from

priming.

All

horizontal suction lines should slope

up to the pump to avoid trapped air

pockets. All piping should be

properly supported.

4

Priming

Remove pipe plug in top of body and

fill the pump body completely with

solids free liquid. In freezing weather

prime pump with warm water.

4

Motor connection

All wiring of motor and control,

overload protection and grounding

should be in accordance with the

National Electrical Code, State and

Local codes. Make motor connection

per label located on motor or motor

manufactures manual.

All units rotate clockwise as viewed

from shaft end of pump. It is

necessary to slide one half of the flex

coupling back when checking

rotation to eliminate the possibility

of unscrewing the impellers which

are threaded on the shaft.

4

Rotation

THIS PUMP SHOULD

N O T B E O P E R AT E D W I T H O U T A

S T R A I N E R O N T H E E N D O F T H E

SUCTION LINE TO PREVENT STICKS,

STONES, RAGS AND OTHER FOREIGN

MATTER FROM BEING DRAWN INTO THE

IMPELLER. THE STRAINER SHOULD BE

CLEANED REGULARLY TO INSURE FULL

FLOW.

CAUTION

4

Suction

Connect discharge hose or pipe to

the discharge port. Make sure all

lines have air-tight joints

4

Discharge

4

Lubrication

Lubrication not required as seal and

impeller are water lubricated and

need no attention.

DO NOT OPERATE PUMP

WITHOUT PRIMING FIRST. OPERATING

DRY WILL DAMAGE SEAL.

CAUTION

To start pump, apply power to motor

per the

MOTOR OR ENGINE

INSTRUCTIONS MANUAL.

4

Starting

Discontinue operation by stopping

the engine as stated in ENGINE

MANUAL or by disconnecting electric

power to motor. It is recommended

to drain and flush pump if pump has

been operating in freezing weather.

4

Shutdown

Turn off and lock out power before

servicing pump.

4

Service

Disconnect suction piping and

remove hex nuts and suction flange.

Remove gasket, weights, screw and

lockwasher and replace if worn or

damaged.

4

Check valve

To replace, the HINGE section of

gasket is at the TOP and the LARGE

weight is on the pump side of gasket.

Disconnect suction and discharge

piping. Remove hex nuts and

lockwashers then remove body and

o-ring from pedestal.

4

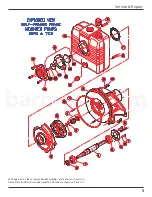

Body, Volute & Impeller

barmesa.com

Содержание BSP5CU

Страница 9: ...8 barmesa com...