Ÿ

Do not insert your finger or a stick into the pump's inlet opening. Doing so may cause injury, electrical

shock, short, or fire.

Ÿ

When the pump is not used for a long time, make sure that the power supply (such as a breaker) is

properly disconnected. If the wiring insulation deteriorates with the power supply connected, it may

cause current leakage, electrical shock or fire.

Ÿ

During inspection and repair, disconnect the power supply to avoid starting the pump unintentionally.

Failure to disconnect the power supply may lead to serious accidents including electrical shock and

injury.

Ÿ

During a power outage, disconnect the power supply to the pump. Unintentional operation of the

pump after power resumption would be extremely dangerous to people around the pump.

24

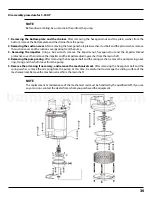

CAUTION

Ÿ

Unless the cause of a problem is removed, the pump will repeat the stop-and-go cycle, eventually

resulting in damage to the pump, and causing current leakage and electrical shock. Therefore, after

verifying that the power supply is disconnected, find and correct the cause of the problem through

inspection and repair.

Ÿ

Do not operate the pump at unusually low head, or when the strainer is clogged with debris. Doing so

will prevent the pump from attaining its full potential, and may also generate abnormal noise and

vibration and cause damage to the pump, which may lead to current leakage, electrical shock and fire.

To protect the motor, if a current overload occurs in the motor or if the motor overheats under the conditions given below,

the pump will stop automatically, regardless of the water level during operation:

Ÿ

Extreme fluctuation of power supply voltage.

Ÿ

Pump operated under overload condition.

Ÿ

Pump operated at open phase or binding condition.

5.4 Motor protection system

WARNING

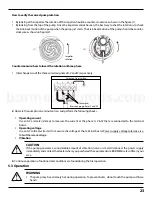

1. Circle thermal protector

Some of the pumps are equipped with an internal motor protective device (circle thermal protector). If an

excessive current is detected or the motor overheats, for reasons such as the following, the pump will

automatically stop operating regardless of the water level to protect the motor:

Ÿ

Change in supply voltage polarity.

Ÿ

Overload.

Ÿ

Open-phase operation or operation under constraint.

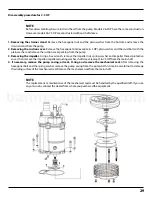

2. Miniature protector

(non-standard configuration)

This protector is embedded inside the motor coil. If the coil should overheat for any reason, bending of the

bimetal of the miniature protector triggers a signal, which in turn causes an external circuit in the starting

console or control panel to shut off the motor current. When the temperature returns to normal, the

protector is automatically reset, but restarting is controlled from the starting console or control panel.

barmesapumps.com

Содержание 2KTM201

Страница 42: ......