4

REGULAR MAINTENANCE

1

.

The safety level of the equipment can be maintained only if it is examined

regularly for damage and wear, e.g. ropes, pulleys, connection points;

2

.

Pay special attention to components most susceptible to wear.

3

.

Replace defective components immediately and /or keep t he equipment out

of use until repair;

4

.

This equipment should carry on regular maintenance according to the

following chart:

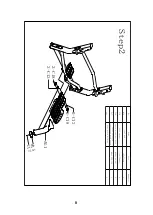

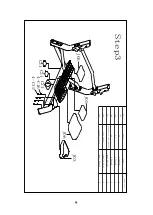

INSTALL SKETCH MAP

Let assembly become easier

All the content of user’s manual is to assured the strength training machine can be

installed more easily

Reading the details and instructions before installing:

1

.

Because the size and weight of equipment is so large, Please choose the installed

place near the desired station and assured there is enough space to exercise

2

.

All parts can be put on the clear area, then backout the wrapper. And the wrapper

can’t be through away before installation finished.

3

.

Screw the bolt tightly except the additional instruction

4

.

All parts must be installed according the illustration indication.

5

.

Installation work can be finished by tow men

6

.

Identify all parts by part identify chart

MAINTENANCE

EVERYDAY EVERY WEEK THREE MONTHS

Check: connecting, bolt,

Weight stack bolt

√

Clearance:

cushion and cover

√

Lubrication:

place of sliding

√

Check:

bolt if tighten

√

Lubrication:

Bracket of bearing

√