50

60

70

80

90

100

110

120

130

140

150

Distance from centre of disc to stylus (mm)

150

200

250

300

350

400

450

500

550

Rotational velocity (mm/sec)

12" 33 1/3 RPM

7" 45 RPM

Figure 3.11: The relative speed of the

stylus to the surface of the vinyl as it

tracks from the outside to the inside ra-

dius of the record.

50

60

70

80

90

100

110

120

130

140

150

Stylus distance from centre of disc (mm)

0.001

0.01

0.1

1

10

100

Wavelength (mm)

20 Hz

100 Hz

1 kHz

20 kHz

Figure 3.12: The wavelengths measured

in the groove, as a function of the sty-

lus’s distance to the centre of a disc.

The shorter lines are for 45 RPM 7“discs,

the longer lines are for 33 1/3 RPM 12“

LPs.

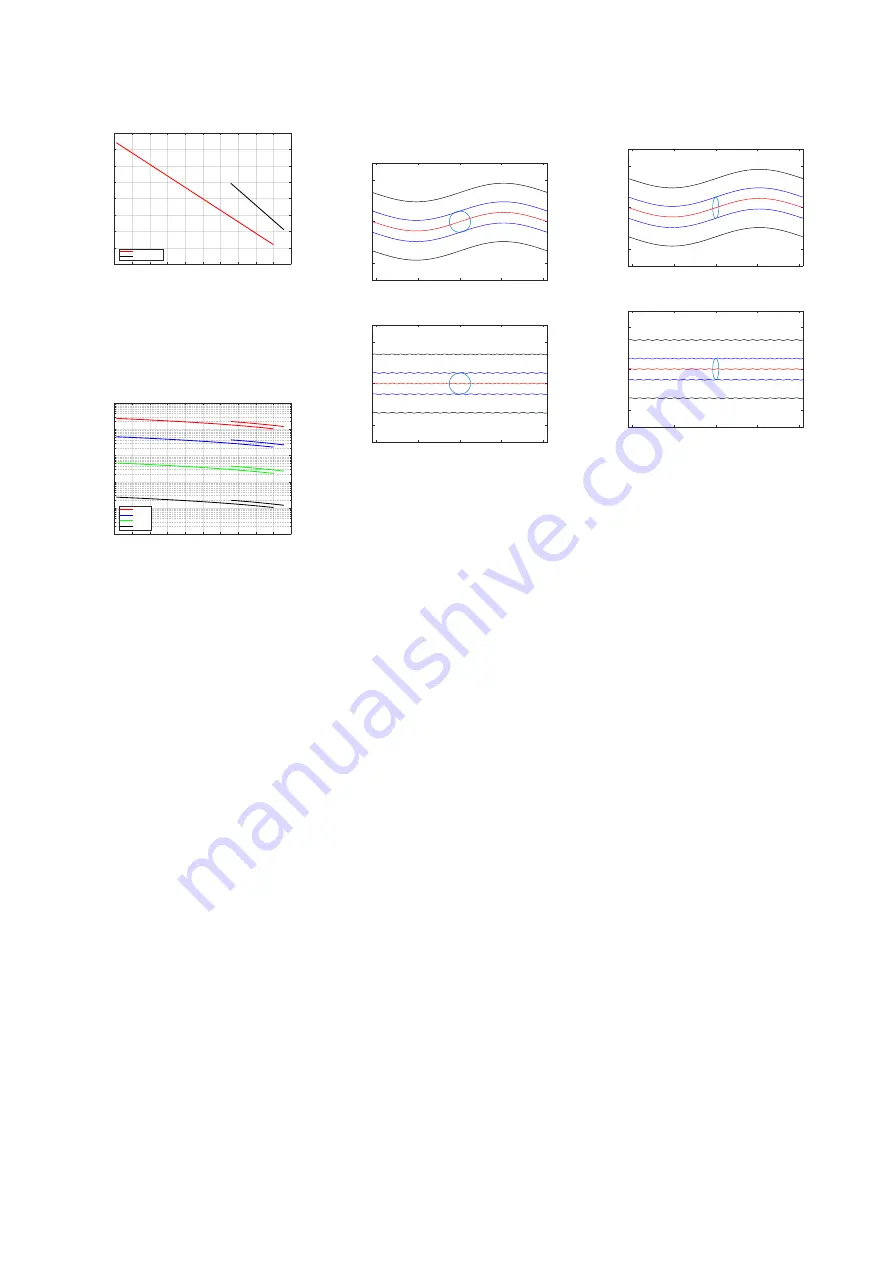

However, now we have a problem. If

the “wiggles” in the groove have a

total wavelength of 11

µ

m, but the tip

of the stylus has a diameter of about

36

µ

m, then the stylus will not be able

to track the groove because it’s simply

too big (just like the tires of your car do

not sink into every small crack in the

road). Figure

shows to-scale

representations of a conical stylus with

a diameter of 36

µ

m in a 70

µ

m-wide

groove on the inside radius of a 33 1/3

RPM LP (60 mm from the centre of the

disc), viewed from above. The red lines

show the bottom of the groove and the

black lines show the edge where the

groove meets the surface of the disc.

The blue lines show the point where

the stylus meets the groove walls. The

top plot is a 1 kHz sine wave and the

bottom plot is a 20 kHz sine wave, both

with a lateral modulation velocity of 70

mm/sec. Notice that the stylus is

simply too big to accurately track the

20 kHz tone.

-100

-50

0

50

100

Groove length (µm)

-50

0

50

Lateral Position (µ

m)

-100

-50

0

50

100

Groove length (µm)

-50

0

50

Lateral Position (µ

m)

Figure 3.13: Scale representations of a

conical stylus with a diameter of 36

µ

m

in a 70

µ

m-wide groove on the inside

radius of a 33 1/3 RPM LP, looking di-

rectly downwards into the groove. See

the text for more information.

One simple solution was to “sharpen”

the stylus; to make the diameter of the

spherical tip smaller. However, this can

cause two possible side e

ff

ects. The

first is that the tip will sink deeper into

the groove, making it more di

ffi

cult for

it to move independently on the two

audio channels. The second is that the

point of contact between the stylus

and the vinyl becomes smaller, which

can result in more wear on the groove

itself because the “footprint” of the tip

is smaller. However, since the problem

is in tracking the small wavelength of

high-frequency signals, it is only

necessary to reduce the diameter of

the stylus in one dimension, thus

making the stylus tip

elliptical

instead

of conical. In this design, the tip of the

stylus is wide, to sit across the groove,

but narrow along the groove’s length,

making it small enough to accurately

track high frequencies. An example

showing a 0.2 mil x 0.7 mil (10 x 36

µ

m) stylus is shown in Figure

.

Notice that this shape can track the 20

kHz tone more easily, while sitting at

the same height in the groove as the

conical stylus in Figure

-100

-50

0

50

100

Groove length (µm)

-50

0

50

Lateral Position (µ

m)

-100

-50

0

50

100

Groove length (µm)

-50

0

50

Lateral Position (µ

m)

Figure 3.14: Scale representations of an

elliptical stylus with diameters of 10 x

36

µ

m in a 70

µ

m-wide groove on the

inside radius of a 33 1/3 RPM LP, look-

ing directly downwards into the groove.

See the text for more information.

Both the conical and the elliptical

stylus designs have a common

drawback in that the point of contact

between the tip and the groove wall is

extremely small. This can be seen in

Figure

, which shows various stylus

shapes from the front. Notice the

length of the contact between the red

and black lines (the stylus and the

groove wall). As a result, both the

groove of the record and the stylus tip

will wear over time, generally resulting

in an increasing loss of high frequency

output. This was particularly a problem

when the CD-4 Quadradisc format was

introduced, since it relies on signals as

high as 45 kHz being played from the

disc. In order to solve this problem, a

new stylus shape was invented by

Norio Shibata at JVC in 1973. The idea

behind this new design is that the

sides of the stylus are shaped to follow

a much larger-radius circle than is

possible to fit into the groove,

however, the tip has a small radius like

a conical stylus. An example showing

this general concept can be seen on

the right side of Figure

.

11