4

5) Routine Maintenance

Refer to preventative maintenance section for frequency.

5.1) Draining the Air Receiver

Drain condensate from air receiver at a pressure of no more than 2 Bar.

Slowly open the red coloured drain tap

provided to allow water to flow out – see fig 5.

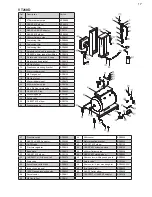

Fig. 5 Drain tap types

Close drain tap when all water has drained off.

Draining is not required on dryer equipped

models.

Automatic drains where fitted do not require draining, however the condensate bottle

will require emptying – see following section “Operation Dryer Models”.

Note !

Waste condensate must be handled in accordance with national environmental rules.

5.2) Check Pressure Relief Valve

Ensure the air receiver is not pressurised.

On “S” models, refer to section 8: Removing

Housing Cover

Unscrew the knurled end of the pressure

relief valve until an audible “click” is heard.

Retighten without using excessive force.

Fig. 6 Pressure relief valve positions

6) Operation – Dryer Models

When equipped with an air dryer unit, the compressor will automatically dry the compressed

air before it is stored in the air receiver. This happens automatically and requires no additional

maintenance.This eliminates the need to manually drain the air receiver.

Operation is similar to standard versions with

the following change :-

Each time the compressor switches off or the

power supply is interrupted, the dryer purge

valve opens and automatically activates

the drain valve on the after cooler filter

allowing the dryer tower to regenerate. All

accumulated moisture will discharge into the

condensate bottle.

This should be emptied when it reaches ¾ full.

Do not exceed the recommended 50% duty cycle, otherwise the dryer will not activate

and the humidity of the air will increase. Ensure the after cooler fins are kept clear of

accumulated dust.

Note!

It is normal for the VTS 250D units to constantly bleed air from the condensate bottle.

Fig. 7 Condensate bottle locations

Содержание VT75

Страница 23: ...21 73...