Routine Maintenance

Refer to preventative maintenance section for frequency. [Page 4]

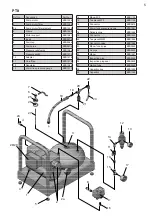

Draining the Air Receiver

Drain water condensate from air receiver at a pressure of

no more than 2 Bar.

Slowly open the drain tap provided to allow water to flow out.

Close drain tap when all water has drained off.

Draining the Filter/Regulator Unit

Slowly open the drain screw provided to allow water to flow out.

Close drain screw when all water has drained off.

Note !

Waste water condensate must be handled in accordance with national environmental rules.

Check Pressure Relief Valve

Ensure the air receiver is not pressurised.

Unscrew the knurled end of the pressure relief valve until an audible “click” is heard.

Retighten without using excessive force.

Technical

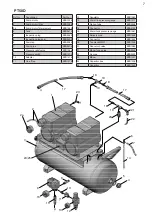

We recommend the compressor has a maximum 65% duty cycle to prolong pump life.

Note !

The motor must never be allowed to run continuously otherwise it will overheat and

may become damaged. The duty cycle is calculated over 10 minutes, meaning that if

the motor runs continuously for 6.5 minutes it must then rest for 3.5 minutes.

Do not ignore air leaks. All air connections must be leak free to prevent the

compressor from over heating.

The compressor is fitted with a thermal overload. In the event of excessive

temperature, the motor will switch off. After about 50 minutes when the motor has

cooled it will automatically reset.

You

must

find the cause of the overload and rectify this before continuing to use the

compressor.

Check for -

•

Drain tap not closed properly

•

Air leaks on the pneumatic fittings

•

Compressor not the correct size for the work load

•

Cooling fan cover vent restricted

If problems persist contact your dealer.

3