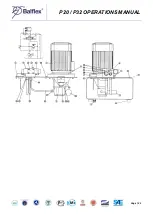

P20 / P32 OPERATIONS MANUAL

Page | 9

TEST RUN

•

Start the motor.

•

Adjust the crimping diameter to 10.0 and the retraction to the maximum value.

•

During the first crimping cycles air in the cylinders may make the piston/dies move irregularly and at high

speed. Cycle the press a few times till the motion becomes even.

•

To avoid accidents, make sure that there are no foreign objects between the dies.

•

In case the dies do not move in either direction, the motor rotates in wrong direction. Correct by interchanging

two phase conductors in the supply disconnecting device.

SELECTING THE DIE SET P20

Use only original BALFLEX die sets in BALFLEX crimping machines.

Refer to the fitting manufacturer's specifications for proper crimping diameter for the fitting. Each die set has its

own crimping range. Follow it to assure the roundest possible crimping result. The minimum crimping diameter D is

marked on each die set. Example: with die set Nº P20/23 the minimum crimping diameter is 23 mm.

Part

Number

Crimping

Range

(mm)

D

(mm)

L

(mm)

Part

Number

Crimping

Range

(mm)

D

(mm)

L

(mm)

P20/10

10.0-12.0

10

55

P20/27**

27.0-31.0

27

70

P20/12

12.0-14.0

12

55

P20/31**

31.0-36.0

31

70

P20/14**

14.0-16.0

14

55

P20/36**

36.0-41.0

36

75

P20/16**

16.0-19.0

16

55

P20/41**

41.0-47.0

41

75

P20/19**

19.0-23.0

19

55

P20/47**

47.0-54.0

47

85

P20/23**

23.0-27.0

23

55

P20/54

54.0-61.0

54

85

Содержание P20

Страница 1: ...OPERATION MANUAL P20 MANUFACTURING YEAR SERIAL NUMBER P32 MANUFACTURING YEAR SERIAL NUMBER ...

Страница 20: ...P20 P32 OPERATIONS MANUAL Page 19 SPARE PARTS LIST ...

Страница 22: ...P20 P32 OPERATIONS MANUAL Page 21 ...

Страница 24: ...P20 P32 OPERATIONS MANUAL Page 23 ELECTRICAL DIAGRAM ...