MAINTENANCE

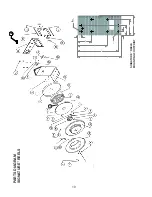

Replacing Power Spring:

1. Be sure the system pressure has been relieved.

Follow the pressure relief procedures.

2. Disconnect inlet hose. Remove the reel to work

bench and clamp reel base securely.

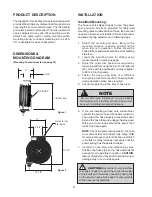

Wrapping hose

ROLLER OUTLET

DELIVERY

HOSE

HOSE

LOOP

BUMPER STOP

SIDE PANEL

HOSE LOOP

Figure 7

Pressure Relief Procedure:

To reduce the risk of serious bodily injury,

including fluid injection or splashing into the eyes

and/or onto the skin, follow this procedure below

before maintaining and/or repairing the pump,

solenoid and/or impulse meter or any part of your

system.

1. Disconnect the air supply from the pump.

2. Open the dispensing valve into an approved

waste container to relieve pressure on the

system.

3. Leave any bleed-type drain valves open until

you are ready to use the system again.

6

MAINTENANCE

Replacing Service hose:

1. Be sure the pressure supply has been

relieved.

Follow the pressure relieve

procedures below.

2. Pull hose on reel down just enough to allow

stop pawl to engage ratchet. This will lock

reel into position.

3. Remove the dispensing valve and hose

stop.

4. Wearing

Heavy Leather Gloves

, firmly

grab the outside edge of the spool with both

hands. Let the spool rotate slowly through

your hands until the spool stops. When

the spool stops the spring tension will be

released. The hose can now be unwrapped

and removed from the reel.

5 From open side of reel begin to wrap new

hose around spool in a clockwise direction.

6. Pull hose out through roller outlet and

reassemble hose bumper stop and

dispensing Control Handle.

7. Position the bumper stop so that the hose

will extend enough so that all operators can

reach it.

WARNING:

Wear Heavy Leather

Gloves

when replacing service hose and/or

replacing power spring to protect your hands

from injury.

!

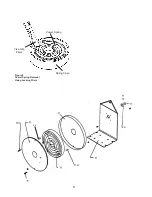

Installing the Derail Bracket

The derail bracket is included with all Signature

Series DEF hose reels.

1. Loosen the two mounting screws,indicated

in the diagram, to allow Derail Bracket

to be inserted under the Mounting Base

(#824455).

2. Adjust Derail Bracket to allow sufficient

clearance for the Hose Reel to spin freely.

Maximum clearance should be no more

than 1/4”.

3. Retighten mounting screws.

Derail

Bracket

Mounting Screws

Hose

Reel

Mounting Base