2

General Safety

Thoroughly read and understand this manual before installing, operating or servicing this

equipment.

Because this Hose Reel can be

incorporated into a pressurized systems,

the following safety precautions should be

observed.

Check equipment regularly and repair or

replace worn and damaged parts.

Never alter or modify any parts of this hose

reel, doing so may cause damage to hose reel

and/or personal injury.

Under no circumstances should the dispensing

valve be aimed at any person at any time.

Personal injury may result.

Release pressures built up in the system

before any service or repair is begun. See the

pressure relief procedure below.

NOTE:

If reel is equipped with hose, reel

maximum pressure will be determined by the

lowest working pressure rating of the hose,

bare reel, or dispense valve.

Always read and follow the fluid manufacturer’s

recommendations regarding the use of

protective eyewear, clothing and respirators.

IMPORTANT

!

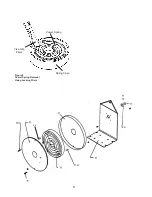

The spring is ALWAYS under great tension and

could be propelled from the case with enough

force to cause serious bodily injury.

CAUTION

USE EXTREME CARE WHEN

HANDLING THE POWER SPRING!

!

Be sure the mounting

surface is strong enough to

support the reels, the

weight of the fluids and the

stress caused by hard pulls on the service

hoses. See page 3 for dry weights of the

hose reel assemblies.

WARNING

!

WARNING

!

The

MAXIMUM WORKING

PRESSURE

of a hose reel is determined

by the lowest rated component in the

assembly. The hose reel Technical Data

chart on page 3 gives the maximum

working pressure of bare reels and reels

assembled at the factory with hose. The

maximum working pressure of a hose reel

is indicated on the hose reel identification

plate located near the base of the reel.

If adding a service hose and dispensing

valve to a bare reel,

BE SURE

you know

the maximum working pressure of

ALL

components!

WARNING

!

DANGER: Not for use with fluids

that have a flash point below

100°F (38°C). Examples: gasoline,

alcohol. Sparking could result in

an explosion which could result in

death.

Pressure Relief Procedure:

To reduce the risk of serious bodily injury,

including fluid injection or splashing into the eyes

and/or onto the skin, follow this procedure below

before maintaining and/or repairing the pump,

solenoid and/or impulse meter or any part of your

system.

1. Disconnect the air supply from the pump.

2. Open the dispensing valve into an approved

waste container to relieve pressure on the

system.

3. Leave any bleed-type drain valves open until

you are ready to use the system again.