4

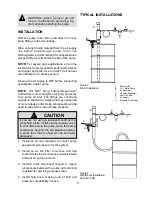

1-1/2” nptm

PRODUCT DESCRIPTION

The “Bobcat

™

130” pump family replaces the

earlier “Trans-Jet 130”, “131A-CB & 131A-CBL”,

“121”, “Econo-Jet” ™ (1.5:1) and P-160/P-161

food pumps. These pumps are suitable for

petroleum products, chemicals, and USDA

applications.

Four versions are currently available, two each

in stub and drum lengths. The 1110-001 and

1110-004 are composed of carbon steel parts

with Buna-N seals for long life.

The 1160-002 and 1160-006 have all “wetted

parts” made from 304 SS or 316 SS and Viton

and are USDA approved.

All pumps contain a pair of 1 inch Delrin

®

balls

which provide compatibility for many fluids and

a smooth flow on both pump strokes. For fluids

more viscous than 90W gear lube, carbon steel or

300-series SS balls may be substituted.

All pumps are composed of a 2-piece body with

the upper section being Aluminum and the lower

section being Aluminum or 316 SS, depending

on model number.

The lower section’s flanged coupling contains a

4-hole bolt pattern which allows 360° rotation of

the inlet and outlet ports in 90° degree increments.

This feature is useful when installing a pump

on a wall bracket that limits orientation of the

hoses.

All pumps contain a pair of internal exhaust

mufflers which provide efficient operation with

low noise levels conforming to OSHA regulations.

These mufflers also act as filters, inhibiting air

line debris from exiting the pump where cleaner

environments are required.

The 1-piece pump air motor is factory-lubricated

with a life-tested, synthetic grease (Balcrank

#826733). This grease coats all internal parts and

repels air line moisture to inhibit corrosion. Steel

components exposed to air line moisture are

surface treated to inhibit corrosion.

NOTE: Delrin

®

is a registered trademark of the

DuPont Company

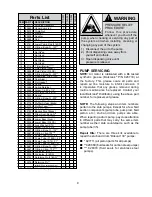

DIMENSIONS &

MOUNTING DIAGRAM

Figure 2

Pump Dimensions

OVERALL LENGTH

MODEL

“A”

“B”

“C”

(Stub Length)

1110-001

26.2”

9.8”

8.2”

1160-002

26.2”

9.8”

8.2”

(Drum Length)

1110-004

50.4” 34.0” 32.4”

1160-006

50.4” 34.0” 32.4”