4 | Baker Hughes

Copyright 2020 Baker Hughes Company. All rights reserved.

Installation

Three-way control valves are most commonly used on either

combining or diverting service. On combining service, the three-

way valve has two inlet ports and one outlet, and is used to

combine two fluids in variable proportions. On diverting service,

the three-way valve is used to split one inlet stream into two

outlets, or the incoming flow can be entirely diverted to one or

the other of the two outlet ports. As shown in the illustrations

opposite, these valves should be installed with flow tending to

open both ports. The principle advantage of this flow direction is

inherent stability.

Three-way valve ports are marked “C” for common, “L” for

lower and “U” for upper. Each of these letters is stamped on its

respective connection to facilitate correct installation.

Before placing the valve in the pipeline, clean the line thoroughly

of all dirt, welding chips, scale, oil or grease and other foreign

material. If valve connections are smaller than size of pipe,

swaged nipples or reducing fittings should be used rather than

bushings. If valve has a finned bonnet, do not insulate bonnet.

Air Piping

Pipe actuating air pressure line to the 1/4” NPT opening: in the

upper diaphragm case if an air-to-extend actuator (Type 37), in

the yoke if an air-to-retract actuator (Type 38). Use 1/4” O.D.

tubing or equivalent for all air lines. If air line exceeds 25 ft. in

length or if the valve is equipped with volume boosters, 3/8”

tubing is preferred. Air lines must not leak.

For valves equipped with 87/88 actuator, please refer to Manual

GEA19530B.

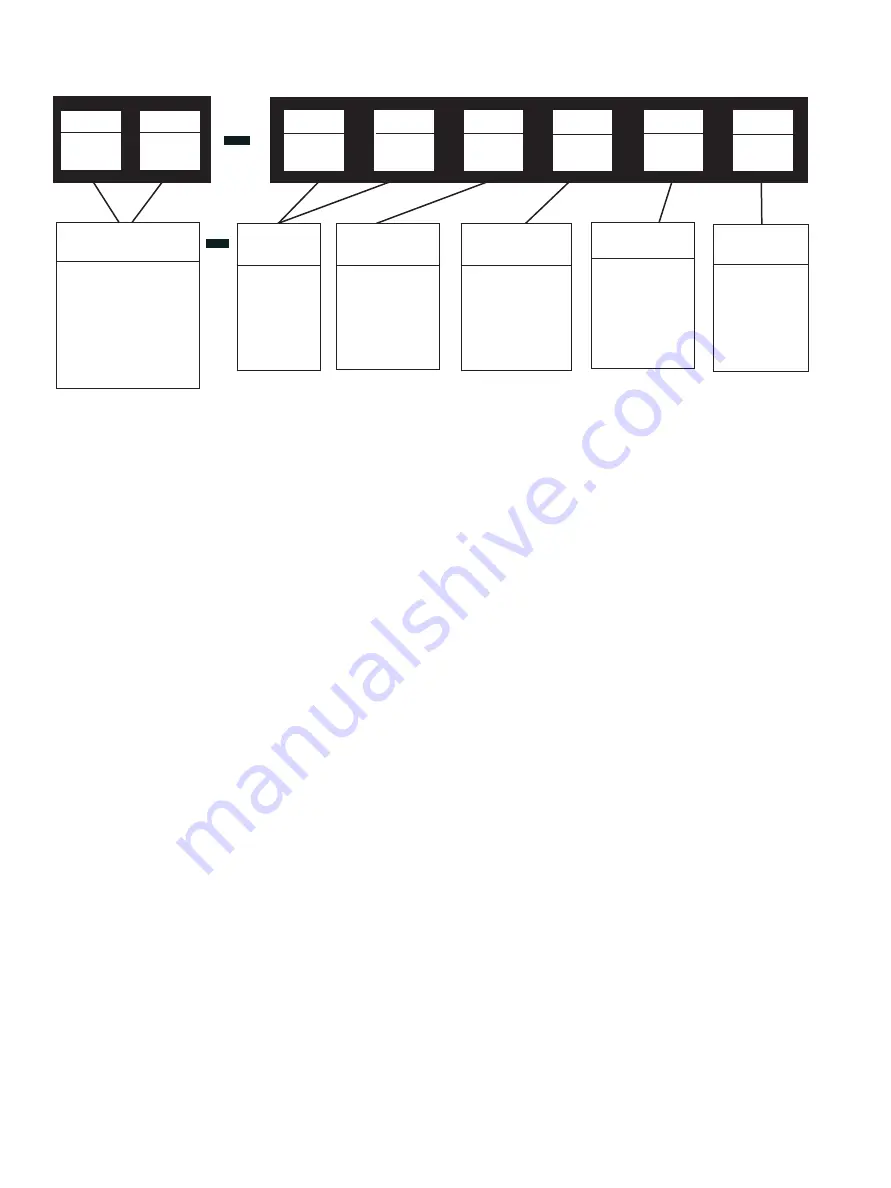

Numbering System

2nd

1st

8

5th

4th

8

3rd

3

2nd

0

1st

8

6th

3. Top and

Port Guided

Plug Type

Body

Series

80

Optional

Configuration

EB Extension

Bonnet

5. Combining

Design

6. Diverting

Design

Seat Type

Control

Characteristics

8. Linear

Ported

Actuator Type

(1)

87 Spring

DiaphragmDirect –

Air to close

88 Spring

DiaphragmReverse

– Air to open

Maintenance

Disassembly – 80385

1.

Apply sufficient air pressure to the actuator to position the

plug just off the upper seat (2).

2.

Remove nuts (48), bottom flange (7) and body gasket (49).

3. With smaller valves, loosen stem locknuts (27), turn them

down the plug stem (5) and lock them. With a wrench

applied over the locknuts, turn the plug stem (5) out of the

actuator stem. With larger valves, remove the split stem

connector (51).

4.

Unscrew drive nut (9) and remove actuator from the valve.

5. Remove locknuts (27) and travel indicator (58). Loosen

packing flange nuts (13) and turn plug stem down and out

of the packing box.

6. Remove plug from the valve body. Examine plug and seat

rings for wear and grind the seating surfaces (see Pages 5

and 6) if necessary.

7.

Remove nuts (48), bonnet (8) and gasket (49) from the

valve body.

8.

Remove old packing (14) with lantern ring (16) from the top

of the bonnet.

9.

Threaded seat rings are set up tightly when assembled

and are usually in service for years before replacement, so

that it is often difficult to remove them. To facilitate removal,

fabricate a special seat ring wrench to engage the seat ring

lugs and attach it to a shock wrench. If rings are exceptionally

stubborn, the application of heat or penetrating oil may

assist in removal.

(1) For valve with travel > 2.5”, actuator model 37/38 should be used.