35

35

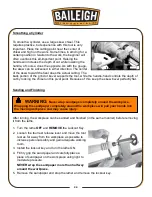

FACEPLATE TURNING

Faceplate turning is when a workpiece is mounted to

the faceplate, which is mounted to the headstock

spindle. This type of turning is usually done with open-

faced workpieces such as bowls.

If screws cannot be placed into the workpiece, then a

backing block must be glued to the workpiece and

attached to the faceplate with screws.

Faceplate Mounting

1. Find the center of your workpiece in the same

manner as when spindle turning.

2. Using a band saw or similar tool, cut off the corners

of the workpiece.

Note: Only use tap screws or wood

screws with non-tapered heads to attach the faceplate

to the workpiece. Do NOT use drywall screws or

screws with tapered heads because these can split the

faceplate or the screws may snap off during operation.

3. Using the centering lines, center the faceplate on

the workpiece and screw the faceplate to the

workpiece.

4. Thread the faceplate onto the headstock spindle

and tighten securely.

Mounting to a Backing Block

1. Make the backing block from a piece of scrap wood that is flat on both sides.

2. Locate and mark the center of both the workpiece and the backing block.

3.

Drill a 1⁄4" diameter hole through the center of the backing block.

4. Using the drilled hole to align the center, glue the center of the backing block to the center of

the workpiece.

5. Clamp the backing block to the workpiece, and wait for the glue to cure according to the

manufacturer’s recommendation.

Содержание WL-1218VS

Страница 3: ...LATHE PARTS DIAGRAM 39 Parts List 40 TROUBLESHOOTING 43 Motor Electrical 43 Wood Lathe Operation 44 ...

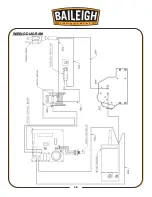

Страница 41: ...38 38 WIRING DIAGRAM ...

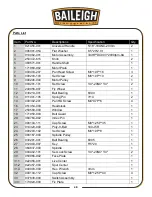

Страница 42: ...39 39 LATHE PARTS DIAGRAM ...

Страница 49: ...46 46 NOTES ...

Страница 50: ...47 47 NOTES ...

Страница 51: ...48 48 NOTES ...