Batch Controller Model CB-30

Page 6

April 2017

CTL-UM-01028-EN-03

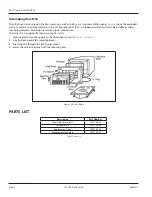

Assembling the CB-30

The CB-30 can be mounted on the flow meter, on a wall or shelf, or in an instrumentation panel

Figure 2

shows the exploded

view of a meter or wall mounted unit In this configuration the CB-30 is shipped separately and must be installed as shown

(see wiring diagrams for proper transmitter signal connections)

The basic unit is equipped for panel mount To install:

1 Measure and cut mounting hole to the dimensions shown in

Figure 1 on page 5

2 Install gasket around the mounting bezel

3 Insert the unit through the front panel cutout

4 Secure the unit to the panel with the mounting clips

Figure 2: CB-30 Assembly

PAOTS LIST

Description

Part Number

Mounting harware kit

259170-005

Connector kit

259170-004

Replacement triac

259170-003

Replacement face plate

259170-002

Table 1: Parts list