Azbil Corporation

36

Model

KFPA

,

KFTA

- Field Mount type Pressure Indicating Controllers

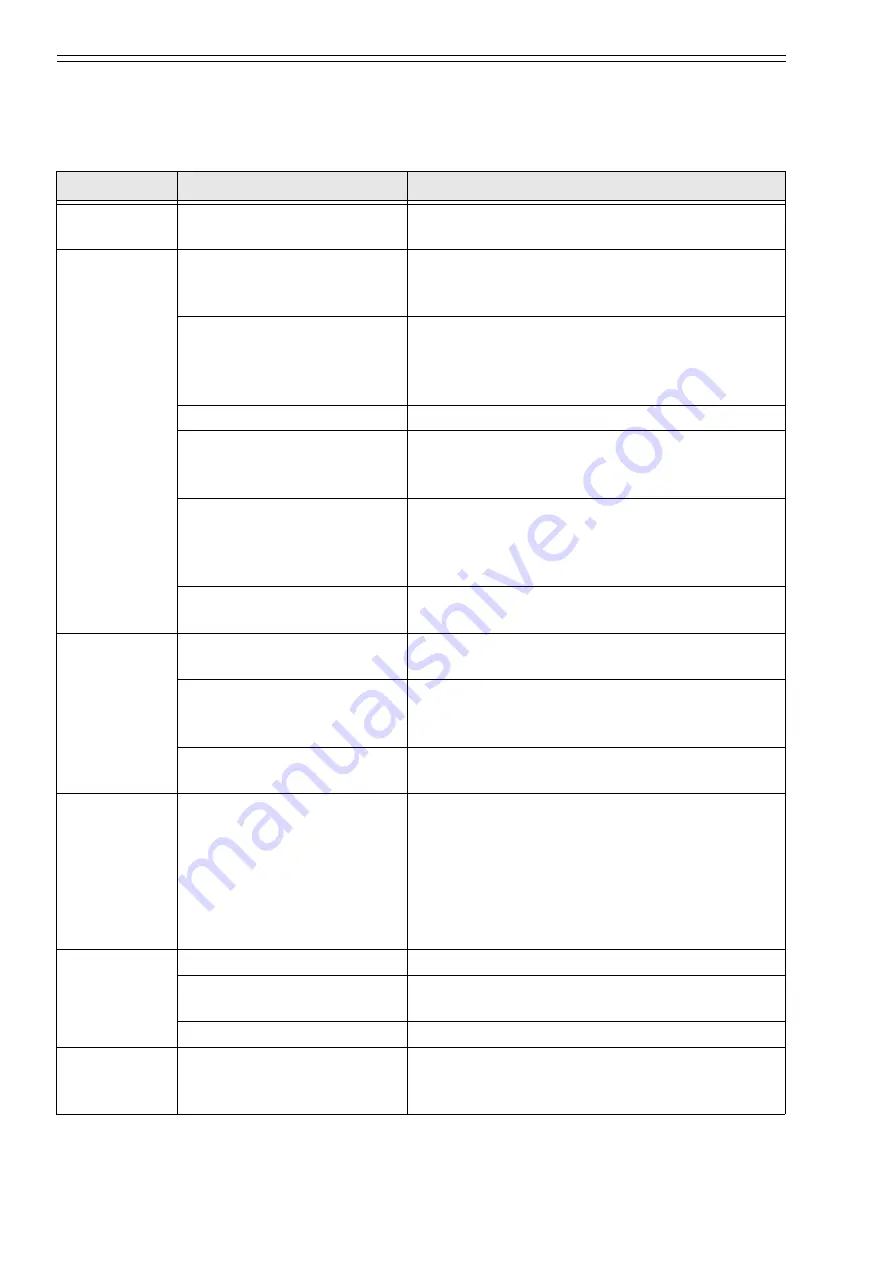

6-5: Troubleshooting

For troubleshooting the instrument, see the following table. For adjustment, refer to the preceding

chapter.

Symptom

Probable cause

Troubleshooting

Pilot relay

whines.

Valve sheet is stained.

Remove pilot relay, and clean valve sheet.

Little or no

control

pressure is

delivered.

Supply air pressure is off or

below 140 kPa {1.4 kgf/cm²}.

Restriction is clogged.

Provide proper supply pneumatic pressure.

Remove restriction and clean it.

Restriction is not correctly set. When no transmitter is used, restriction is provided

with blind plug. Reattach it to correct position.

Correctly set restriction(s) and plug depending on

whether the instrument has transmitter or not.

Filter is badly stained.

Replace filter

There is leakage in nozzle

circuit of indicating control

section.

After making sure that O-rings are properly

attached, firmly tighten the controller unit and

restriction.

There is leakage or choking in

A/M transfer circuit. (When

A/M transfer switch is

provided.)

Remove manual control unit and make sure that

circuit is correct and that O-rings of connecting

section are properly attached. Then, firmly tighten

the unit.

There is leakage from pilot

relay diaphragm.

Remove pilot relay, check diaphragm and, in case

of leakage, replace diaphragm.

Control

pneumatic

pressure is too

high

Nozzle of indicating control

section is clogged.

Clean nozzle.

Restriction screw of indicating

control section is not in firm

contact with sheet surface.

Tighten so that sheet surface of restriction screw is

contacted with the manifold.

Valve sheet of pilot relay is

stained.

Remove pilot relay and clean valve sheet.

Input offset in

indication is

large.

Set point pointer or measuring

pointer is shifted.

Readjust deviation generating mechanism and

indicating mechanism. (See “5: Calibration and

adjustment”.)

Control mechanism is not

properly adjusted.

(Proportional band is not

properly balanced.)

Adjust the balancing of control mechanism. (See

“5: Calibration and adjustment”)

Reset rate is

abnormal or

ineffective.

Needle or sheet is damaged.

Use new needle assembly.

Dial attaching screw is noose. Set dial in correct position and fix it firmly with

screw.

Air is leaking from gasket.

Firmly fix it to the base.

Manual control

pressure does

not rise.

Supply pneumatic pressure is

not applied or below 140 kPa

{1.4 kgf/cm²}.

Supply proper supply air pressure.