General Safety Instructions

7

It is good practice to leave the machine unplugged until work

is about to commence, also make sure to unplug the machine

when it is not in use, or unattended. Always disconnect by

pulling on the plug body and not the cable.

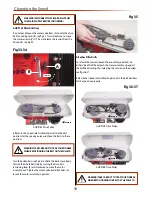

Once you are ready to commence work, remove any tools used

in the setting operations (if any) and place safely out of the

way. Re-connect the machine. Carry out a final check e.g. check

the drill bit is securely tightened in the machine, check you

have the correct speed and function set, check that the power

cable will not ‘snag’ etc.

Make sure you are comfortable before you start work,

balanced, not reaching etc. If the work you are carrying out

is liable to generate flying grit, dust or chips, wear the appro-

priate safety clothing, goggles, gloves, masks etc. If the work

operation appears to be excessively noisy, wear ear-defenders.

If you wear your hair in a long style, wearing a cap, safety hel-

met, hairnet, even a sweatband, will minimise the possibility of

your hair being caught up in the rotating parts of the machine.

Likewise,consideration should be given to the removal of rings

and wristwatches, if these are liable to be a ‘snag’ hazard.

Consideration should also be given to non-slip footwear, etc.

DO NOT work with cutting or boring tools of any description

if you are tired, your attention is wandering or you are being

subjected to distraction. A deep cut, a lost fingertip or worse is

not worth it!

DO NOT use this machine within the designated safety areas of

flammable liquid stores or in areas where there may be volatile

gases. There are very expensive, very specialised machines for

working in these areas, THIS IS NOT ONE OF THEM.

CHECK that drills are the correct type and size, are undamaged

and are kept clean and sharp, this will maintain their operating

performance and lessen the loading on the machine. Above all,

OBSERVE…. make sure you know what is happening around

you, and USE YOUR COMMON SENSE.

General Safety Instructions for Drilling Machines

1. DO NOT operate the machine without carrying out

a preliminary inspection.

2. CHECK that the speed is correct for the planned operation,

and the upper drive belt cover is closed and fastened secure.

3. CHECK the drill bit is the correct size and type, is correctly

fitted and tightened in the chuck.

4. Make sure that the drillhead, the table bracket arm, the table

tilt and the table swivel clamps are all locked before any drilling

is attempted.

5. DO NOT attempt to carry out any drilling operation on

material that has not been secured to the drill table, either by

vice or clamp.

6. Remove any tools (chuck key, spanners etc), that may have

been used in setting up operations and put them away in their

correct stowage positions.

7. Try to arrange the drilling operation so that the drill tip does

not come in contact with the table.

8. ALWAYS allow the drill to stop before removing drills or swarf

from around the job or the table.

9. NEVER remove ‘flying’ swarf strands from the drill whilst it is

turning.

10. It is a good precaution to wear eye protection when drilling,

especially using small drills, or very hard material that produces

small chips.

11. It is not a good idea to wear gloves when

operating a drill press.

12. After the job is completed, remove all tools and accessories

from the machine, check that drill bits are still sharp and re-use

able.

13. Clean the machine down thoroughly, including removing

coolant or cutting compounds from the drill table.

14. Lightly coat all metal surfaces with a light oil coating.

15. Disconnect the machine from the supply. Secure the cable/

plug clear of the floor.

Содержание AHDP13B

Страница 4: ...What s Included 4 1 2 3 4a 2c 4 ...

Страница 5: ...What s Included 5 2b 2e 2d 2a 5 6 10 9 7 8 13 11 12 2f ...

Страница 24: ...Exploded Diagram Parts List 24 AHDP13B Bench Pillar Drill ZQJ4113A ...

Страница 26: ...Exploded Diagram Parts List 26 AHDP16B Bench Pillar Drill ZQJ4116Q ...

Страница 28: ...Exploded Diagram Parts List 28 AHDP16F Floor Pillar Drill ZQJ4116A ...

Страница 30: ...Exploded Diagram Parts List 30 AHRD16B Bench Radial Drill ZQJ3116 AHRD16F Floor Radial Drill ZQJ3116A ...

Страница 34: ...Wiring Diagram 34 ...

Страница 35: ...CE Certificate 35 AHDP13B Bench Pillar Drill ZQJ4113A AHDP16F Floor Pillar Drill ZQJ4116A ...

Страница 36: ...CE Certificate 36 AHDP16B Pillar Drill ZQJ4116Q ...

Страница 37: ...CE Certificate 37 AHRD16B Bench Radial Drill ZQJ3116 AHRD16F Floor Radial Drill ZQJ3116A ...

Страница 38: ...Notes 38 ...

Страница 39: ...Notes 39 ...