Apply Control Power and Reset to Factory Defaults

Once the preliminary wiring previously described is complete, control power can be applied to the servo.

Apply 110VAC or 220VAC power to L1C and L2C (the actual connector on small drives may be labeled

“L1” and “L2”); and apply 24VDC to the I/O (CN1 connector).

To ensure that the drive has all default settings, reset the drive. To do this, enter a value of 10 into

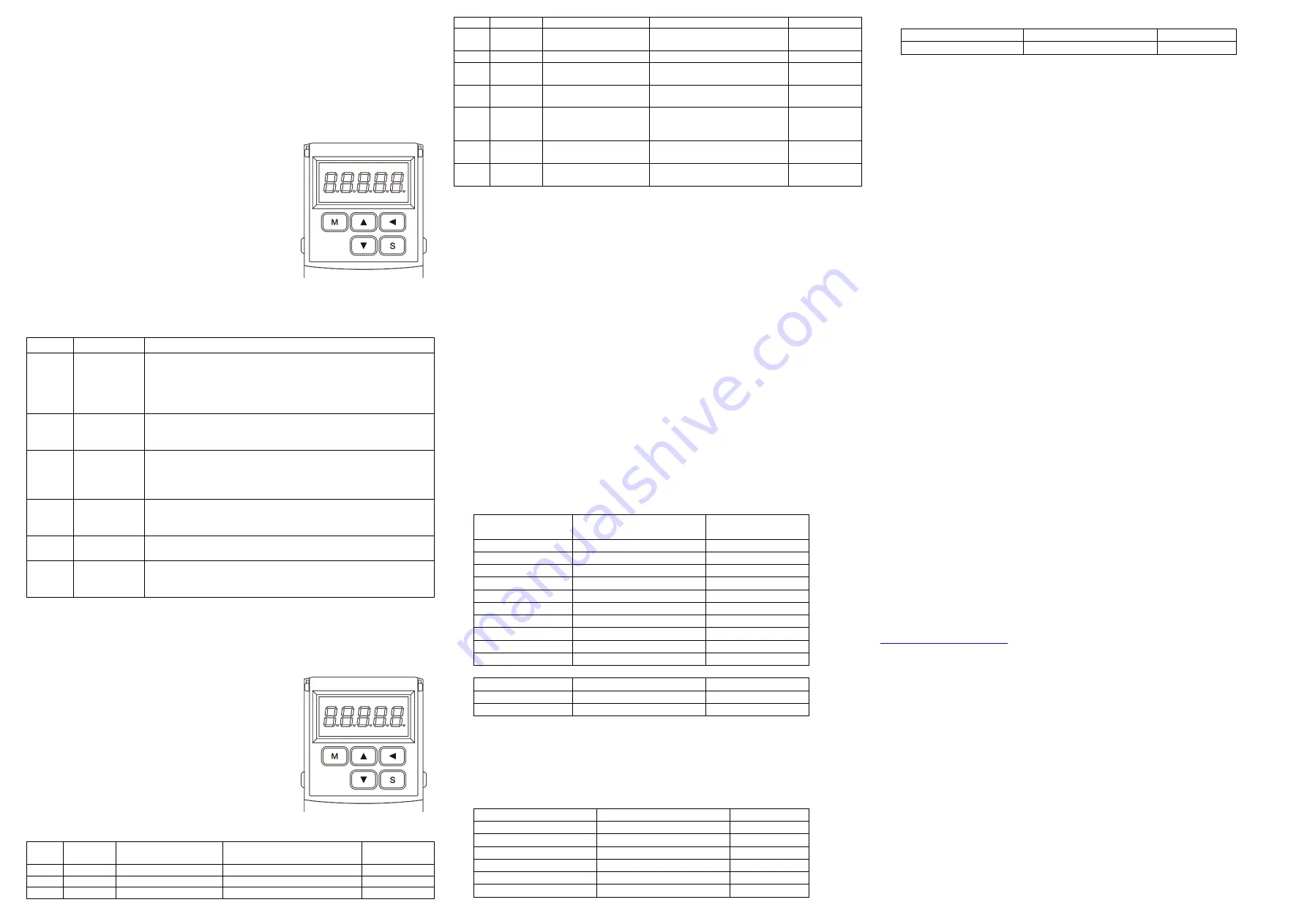

P2.008. On the drive’s keypad:

[These are the general instructions on how to set any Parameter address value]

1.

Press

M

to enter Parameter Mode. (Press

M

until

you see a parameter address that begins with

P

,

like

P0.000

.)

2.

Press ◄ to advance to the

P2

group

3.

Press

▲

or

▼

to advance to

P2.008

4.

Press

S

to enter

P2.008

and see the current value

5.

Press

▲

or

▼

to change the value to

10

6.

Press

S

to set the value.

7.

The drive will display SAVED, BUSY, then DONE.

Cycle power to the drive. The drive will now

contain all factory default settings.

Clear the Alarms

The drive will power up with alarms. The most common alarms are listed below with the most common

solutions. For more detailed information and all possible alarm codes, search for the alarm code (ALxxx)

in the SS2 UM.

Display

Alarm Name

Solution (see the UM for more details)

AL500

STO Enabled

Enable the safety circuit to connect the STO signals (CN10). When the

safety circuit is enabled, this alarm can be cleared. Reset with DI5

Alarm Reset. For temporary testing

without a load attached to the

motor

, the supplied jumpers on the CN10 connector can bypass the

STO feature.

AL501

AL502

AL503

STO Errors

These alarms occur when the STO inputs are not simultaneously

active/inactive. Ensure proper wiring and activation of the safety circuit.

Reset by cycling power to the drive.

AL003

Undervoltage

This alarm occurs when the main motor power (R,S,T) is not present

and the Servo On input (DI1) is ON. At this point of commissioning,

ensure that R,S, and T do NOT have power and that DI1 is OFF.

Reset this alarm with DI5 Alarm Reset.

AL011

Encoder error

Ensure the encoder is connected. Verify the wiring on CN2. Ensure the

motor ground and drive ground are properly connected. Reset by

cycling drive power.

AL013

Motor Override

Ensure that DI8 Motor Override is ON (DI8 is configured Normally

Closed as default). ON = current flowing = no fault.

AL014

AL015

Overtravel

Limit

Ensure that DI6 and DI7 are ON or redefine the inputs (see below).

These inputs are defined Normally Closed as default. ON = current

flowing = no fault.

Change the Digital Input Definition

If the application does not call for Overtravel limits, the definitions of DI6 and DI7 can be changed so that

alarms AL014 and AL015 are not active. To disable DI6 and DI7 by changing parameters through the

keypad, perform the following keystrokes:

1.

Press

M

to enter Parameter Mode. (Press

M

until you

see a parameter address that begins with

P

, like

P0.000

.)

2.

Press ◄ to advance to the

P2

group

3.

Press

▲

or

▼

to advance to

P2.015

(DI6 functional

planning)

4.

Press

S

to enter

P2.015

and see the current value

(default = 022 = Negative overtravel)

5.

Press

▲

or

▼

to change the value to

000

to disable

the input

Note: ◄ moves the cursor left one digit (required for

some parameter entry)

6.

Press

S

to set the value.

7.

Repeat the procedure to disable

P2.016

(DI7) if desired.

Digital

Input

Input Def.

Parameter

Default Definition (hex

values)

Notes (corresponding Alarm)

Necessary for

startup

DI1

P2.010

0101 = Servo On

Enables the servo

Yes

DI2

P2.011

0104 = Clear Pulses

Clears accumulated input pulses

No

DI3

P2.012

0116 = Torque Cmd 0

Torque Select Bit 0 (when in

No

Torque mode)

DI4

P2.013

0117 = Torque Cmd 1

Torque Select Bit 1 (when in

Torque mode)

No

DI5

P2.014

0102 = Alarm Reset

Clears alarms

Yes

DI6

P2.015

0022 = CW Overtravel

Disables motion in CW direction

(AL014)

Yes (or disable

to clear alarms)

DI7

P2.016

0023 = CCW Overtravel

Disables motion in CCW

direction (AL015)

Yes (or disable

to clear alarms)

DI8

P2.017

0021 = Motor Override

Stops motor immediately.

(AL013). Motor can restart when

this DI is switched OFF

Yes

DI9

P2.036

0100 = Disabled

Defined as Disabled and

Normally Open

No

DI10

P2.037

0100 = Disabled

Defined as Disabled and

Normally Open

No

NOTE: Setting the least two digits of P2.010 – P2.037 to 00 disables the input.

The third digit signifies Normally Open or Normally Closed.

Input Definitions with 1xx are Normally Open. DI is ON when current is flowing thru the terminals.

Definitions with 0xx are Normally Closed. DI is ON when current is NOT flowing thru the terminals.

(It is recommended to set disabled inputs to 100, so the logic states are OFF when not energized.)

Verify Encoder Feedback

On the keypad, press

M

to cycle the display off of Parameter addresses (

P2.015

, etc.) or any active

alarms (AL500, etc.). The display will now show Drive Status. Press

▲

or

▼

until

Fb.PUU

is displayed.

After 1 second, the drive will display the Feedback Pulses in User Units. Rotate the shaft manually

clockwise. The display should increment from 0-99,999 for one motor rotation. Decimal points beside the

4

th

and 5

th

digits indicate a negative position. This is a quick indication of which side of absolute zero the

motor feedback is on. If an encoder alarm or unexpected feedback is seen, check all encoder cabling

from the drive’s CN2 to the motor. Check for loose connections or crossed wiring. See the UM for more

help.

Verify Digital Inputs

Set

P0.002

to 39 to display the DI status (in hex format) on the drive’s LED display. As long as energizing

the input does not trigger an alarm, the LED display will report the Digital Input status in hex. If an input

does trigger an alarm (example: if DI8 is set for Motor Override and the input is ON), AL.xxx overrides the

DI display (AL013 = Motor Override). Press

M

to cycle the LED back to the DI status display.

If the Digital Input is defined as Normally Closed (the function code is 0xx), the input will be considered

active (ON) if there is no current flowing thru the terminal. Note: inputs defined as 000 are disabled, but

are considered ON (Normally Closed) if there is no current flowing thru the terminals. To redefine the

inputs, see

Change the Digital Input Definition

section above.

If this is the only input

that is ON

This is the LED display (data

in hex) when P0.002 = 39

Data in binary (DI1 =

bit 0, DI2 = bit 1, etc.)

DI1

L0001

0000 0000 0000 0001

DI2

L0002

0000 0000 0000 0010

DI3

L0004

0000 0000 0000 0100

DI4

L0008

0000 0000 0000 1000

DI5

L0010

0000 0000 0001 0000

DI6

L0020

0000 0000 0010 0000

DI7

L0040

0000 0000 0100 0000

DI8

L0080

0000 0000 1000 0000

DI9

L0100

0000 0001 0000 0000

DI10

L0200

0000 0010 0000 0000

If multiple inputs are ON at the same time, add the above results.

If these inputs are ON

LED display (P0.002 = 39)

Data in binary

DI1 and DI2

L0003

0000 0000 0000 0011

DI4 and DI5

L0018

0000 0000 0001 1000

Verify Digital Outputs (DOs)

The Digital Outputs can be forced ON without requiring the corresponding DO function to be active. To

put the outputs into Diagnostic Mode, set

P2.008

to the value 406. Select the Digital Outputs to force ON

and OFF by setting the hex value in

P4.006

. Each DO is forced ON by the corresponding bit set in

P4.006

. (DO1 = bit 0, DO2 = bit 1, etc.). Press ◄ to move the cursor left one digit. Press

S

to set (apply)

the force to the outputs.

To force this output ON

Set this value in

P4.006

Data in binary

DO1

0001

0000 0001

DO2

0002

0000 0010

DO3

0004

0000 0100

DO4

0008

0000 1000

DO5

0010

0001 0000

DO6

0020

0010 0000

Multiple outputs can be forced ON at the same time. Examples:

DO1 + DO2

0003

0000 0011

All (DO1-DO6)

003F

0011 1111

Once DO testing/verification is complete, exit DO Diagnostic Mode by cycling control power to the drive.

Connect Motor Power and Spin the Motor (w/o load)

NOTE: It is highly recommended to not connect the motor to the load before verifying proper motor

operation. When first spinning the motor, the shaft should not be connected to anything.

1.

Connect a motor power cable to the motor and drive (Ground=green, U=red, V=white,

W=black).

2.

Re-verify incoming control power (L1C, L2C), DI/DO wiring (including 24VDC power), and STO

wiring (CN10).

3.

Ensure that the Servo ON input (DI1) is not ON.

4.

If using a brake motor, connect 24VDC to the brake wires to release the brake. Polarity is not

important.

5.

Connect incoming main power to the drive (Ground, R,S,T).

6.

If any alarms are present, correct the alarms (refer to the explanation above for common

alarms, refer to the UM for more information).

The drive can be jogged from the keypad to verify operation.

7.

Enable the Servo ON input with DI1. The motor should lock into position.

8.

Refer back to Step #4. It is embarrassing if you forget to release the brake.

9.

Set the desired Jog Speed in

P4.005

(or press

S

to accept the default 20rpm in

P4.005)

:

The display will now display

-JOG-

NOTE: If the display shows SV-On, enable Servo ON with DI1 and repeat Step 9

10.

Use

▲

and

▼

to jog the motor forward and reverse.

Press

M

to change speed.

Cycle the drive’s control power to exit Jog Mode.

NOTE: the display will not annunciate alarms while in Jog Mode.

Once the motor successfully jogs, the motor, feedback, and drive have been shown to be properly

installed. The system can now be programmed and commissioned along with the control system.

There are tables at the beginning of Parameters Chapter 8 that detail the most common parameters

used for the different drive control modes:

PT

Mode:

P

osition control –

T

erminals (high speed pulse input commands)

PR

mode:

P

osition control –

R

egisters (point-to-point moves using internal registers for setpoints)

This mode includes point to point moves, registration, and camming

S

Modes:

S

peed/Velocity control

S

= analog input speed command

S

z = internal speed registers that include a zero-speed setting

T

modes: Torque control

T

= analog input torque command

T

z = internal torque registers that include a zero-torque setting

Firmware Upgrade

Occasionally, there will be new servo drive firmware to add new features or correct problems. Go to

http://www.automationdirect.com

and search for your servo drive part number. On that part number's

item page you will find a link for the latest SureServo2 firmware. Compare the website’s current firmware

version to P0.000 (firmware version) and P5.000 (firmware sub-version) in the servo drive. If the versions

match, your drive has the latest firmware. If the online version is higher than P0.000, download the

firmware file from automationdirect.com. Next, open SureServo2 Pro software and connect to the drive.

Then select "Burn" from the pull-down menus to update your drive's firmware. Please see the

SureServo2 Pro help file for detailed instructions and more information.