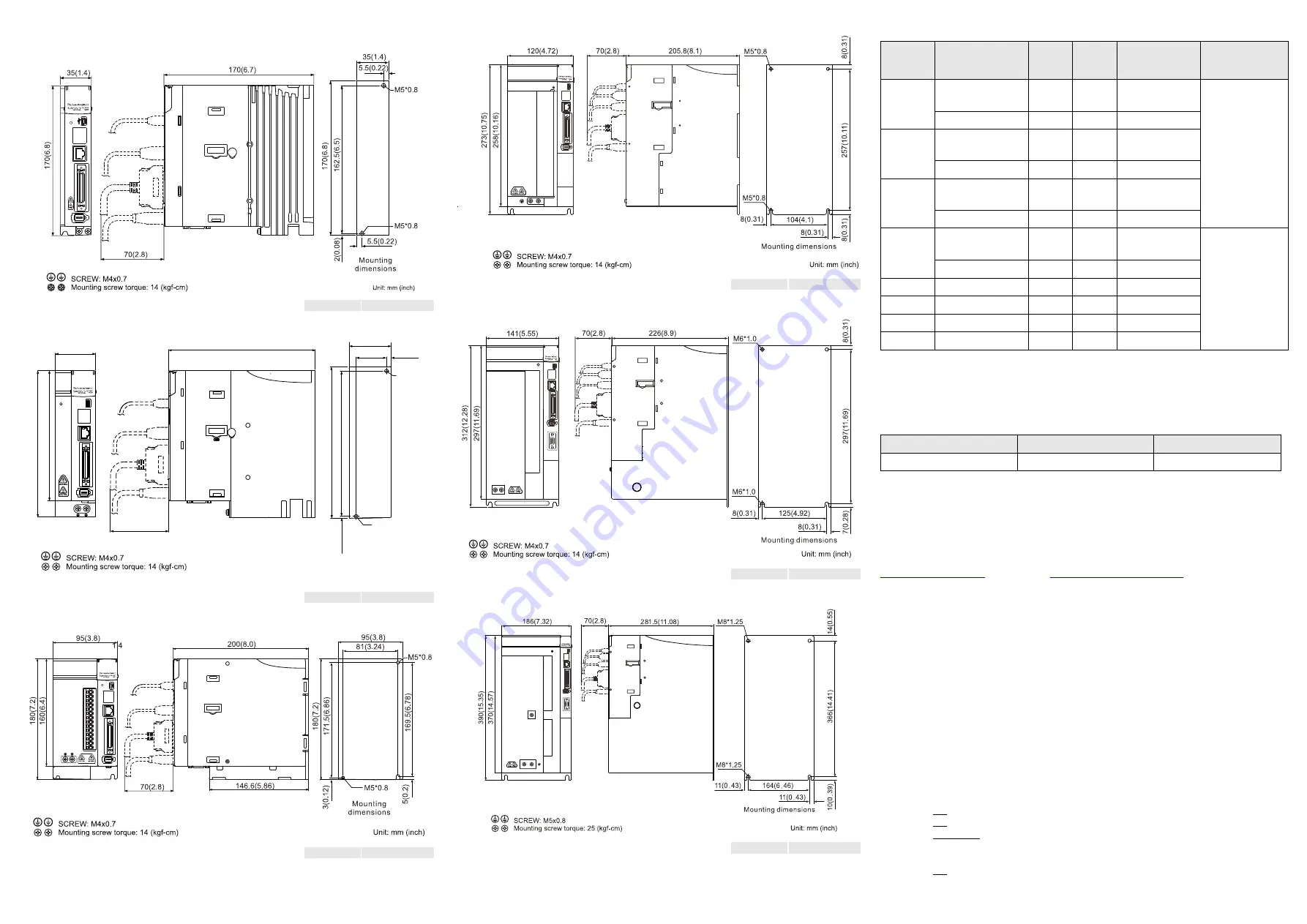

(9) Dimensions and weight of servo drive

SV2A-2040 model

SV2A-2075, SV2A-2150 models

180(7.1)

70(2.8)

5.5(0.22)

50(2)

36.3(1.43)

2

.1

(0

.0

8

)

1

8

0

(7

.2

)

1

7

2

.5

(6

.9

)

M5*0.8

M5*0.8

1

6

0

(6

.3

)

50(2)

1

8

0

(7

.2

)

Unit: mm (inch)

M ou nti ng

di men si on s

Weight

1.3 kg (2.87 lb)

SV2A-2200, SV2A-2300 models

Weight

2.7 kg (5.94 lb)

SV2A-2550 model

Weight

5.5 kg (12.13 lb)

SV2A-2750 model

Weight

7.5 kg (16.53 lb)

SV2A-2F00 model

Weight

15 kg (33.07 lb)

Note: the values displayed in the above figures are measured in metric units. The values displayed in imperial units are

for reference only.

(10) Circuit Protection (maximum allowable values)

Servo drive

model

Main Voltage Level

Drive

Rated

Input

Circuit

breaker

Fuse

Fuse Class

SV2A-2040

100-120VAC 1-phase

200-230VAC 1-phase

3.98 A

4.69 A

10A

15A

Class CC

200-230VAC 3-phase

2.76 A

10A

10A

SV2A-2075

100-120VAC 1-phase

200-230VAC 1-phase

7.73 A

8.71 A

20A

20A

200-230VAC 3-phase

5.09 A

13A

15A

SV2A-2150

100-120VAC 1-phase

200-230VAC 1-phase

12.56 A

14.82 A

30A

30A

200-230VAC 3-phase

8.09 A

20A

25A

SV2A-2200

100-120VAC 1-phase

200-230VAC 1-phase

18.03 A

20.83 A

40A

40A

Class J

Or

High Speed J*

200-230VAC 3-phase

11.36 A

30A

35A

SV2A-2300 200-230VAC 3-phase 14.52 A

35A

50A

SV2A-2550 200-230VAC 3-phase 27.06 A

60A

70A

SV2A-2750 200-230VAC 3-phase 37.33 A

70A

80A

SV2A-2F00 200-230VAC 3-phase 69.95 A

120A

125A

* Edison JHL fuses

These circuit protection values are the

maximum

values allowed by UL. See section

3) Wire Selection

for recommended wire and circuit protection values. Always follow all local and national electrical codes

when selecting circuit protection.

Separate fuses/breakers can be used for the control circuit. Install two fuses or a double pole breaker if

the control power will be using two phases of a 3-phase system. Due to inrush, each drive control circuit

should have separate circuit protection (don’t supply two drives with one breaker).

Control Power

Circuit breaker

Class CC Fuse

All models

5A

6A

(11) Quick Start Guide

This section will show how to safely and quickly start up a SureServo2 (SS2) drive. Wiring and starting

up the drive should only be performed by a qualified professional. High voltage levels are in use.

Commissioning is quicker and easier using the drive configuration software SV2-PRO, but the entire

start-up procedure can be accomplished with the keypad (detailed here). For further information and

more complete startup instructions, please download the SureServo2 User Manual (SS2 UM) from

www.automationdirect.com/videos

SureServo2 commissioning, programming, and operation.

Preliminary Wiring

To safely and quickly start up a SureServo2 (SS2) drive, several different types of wiring need to be

verified first. Until this wiring and functionality is verified, it is highly recommended to NOT connect main

incoming power (R,S,T) or connect the load to the motor shaft.

1.

Connect the ground wires to the screws at the bottom of the drive. Connect the incoming

ground to one screw and connect the motor ground to the other screw. (The motor ground

wire is in the motor cable SV2C-Pxxx-xxxx.)

2.

Connect the wiring for L1C and L2C (single phase 100-120VAC or 200-230VAC). This is

control power and should be continuously available (not disconnected with E-stop, etc.).

3.

Connect an appropriate safety circuit to CN10. See the wiring diagram elsewhere in this

document or the SureServo2 User Manual. Although the CN10 connector comes pre-wired

with an STO bypass, it is strongly recommended to wire a safety relay to connect

STO_A

to

/

STO_A

and to connect

STO_B

to

/

STO_B

.

4.

Connect the motor encoder cable (SV2C-

E

xxx-xxxx) to the motor and to CN2 of the drive.

5.

Connect the appropriate 24VDC input devices to DI1-DI10. Pay close attention to these

Digital Input (DI) definitions. Their default (out-of-the-box) configurations are listed below.

DI1 = Servo On input (wired normally open)

DI5 = Alarm Reset (wired normally open)

DI6 and DI7 = Overtravel inputs. Inputs are wired normally closed (in a fail-safe manner).

If the application is rotary and has no overtravel inputs, these inputs can be temporarily

wired to DC common (0 volts) or disabled thru programming (procedure shown below).

DI8 =Override (temporary Motor Stop input wired normally closed). NOTE: The STO input

(CN10) is separate from the Override (temporary Motor Stop input wired normally closed)

input DI8.

Weight

0.92 kg (2.02 lb)