2

www.automationdirect.com/click-plc

3505 HUTCHINSON ROAD

CUMMING, GA 30040-5860

1-800-633-0405

C2-03CPU Quick Start Guide

Copyright© 2020,

Automationdirect.com

Incorporated/All Rights Reserved Worldwide

Safety Warnings

Please follow these instructions for personal and operational safety.

WARNING

Assumes that incorrect handling may cause hazardous

conditions, resulting in severe injury or death.

CAUTION

Assumes that incorrect handling may cause hazardous

conditions, resulting in medium or slight injury, or

may cause equipment damage.

WARNING

Don’t use this equipment in a flammable or explosive

environment in order to avoid accidental injury or fire.

You should use external electromechanical devices that are

independent of the PLC (Programmable Logic Controller)

system to provide protection for any part of the system;

otherwise malfunction or output failures may result in a

hazardous accident.

24VDC power is required from a secondary circuit or a specific

power supply unit only.

Ensure the Ground Terminal of the Power Supply (C0-00AC/

C0-01AC) for the CLICK PLUS CPU is connected to Earth

Ground to avoid electric shock or equipment damage during a

short circuit.

Don’t operate the equipment with a nonconforming external

power supply to avoid electric shock, equipment damage or fire.

Don’t intentionally fault the wiring; this may cause equipment

damage or fire.

To avoid electric shock or malfunctions which might result in an

accident, don’t touch any terminal while the PLC power is on.

Don’t put metals (e.g. screwdriver) into vent holes, or drop trash

or foreign objects (e.g. wire cut-offs) into the device, in order to

avoid electric shock or equipment damage.

If the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be

invalidated.

CAUTION

For use in Pollution Degree 2 Environment. Use and store the

equipment in an environment described in the specifications

(regarding temperature, humidity, vibrations, shock, etc.) in

order to avoid equipment damage or fire.

Ensure all wiring has strain reliefs in order to avoid damage to

insulation that might result in electric shock or fire.

Ensure secondary external power circuits are only live after PLC

control program is started; otherwise a malfunction or output

failure may result in a hazardous accident.

Don’t block the vent holes. This may cause an increase of inter-

nal temperature resulting in equipment damage or fire.

Don’t disassemble or modify equipment so as to avoid electric

shock, equipment damage, or fire.

Cut off all phases of the external power source before mainte-

nance work, thus avoiding electric shock or equipment damage.

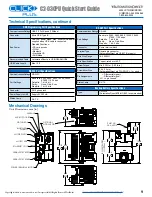

Hardware Installation

ENCLOSURES

It is important to select the appropriate enclosure to ensure

safe and proper operation of your CLICK PLUS PLC

system. Please use this product in a metal enclosure/cabinet.

Control applications vary and yours may require additional

considerations. At a minimum your enclosure should include:

Conformance to electrical standards

Protection from the elements in an industrial environment

Common ground reference

Maintenance of specified ambient temperature

Access to equipment

Security or restricted access

Sufficient space for proper installation and maintenance of

equipment

CLEARANCES AND ORIENTATION

Mount the unit horizontally to

provide proper ventilation.

There is a minimum clearance

requirement of 2in. (51mm)

from all sides of the cabinet and

the equipment.

There is a minimum clearance

requirement of 1.5 in. (38mm)

from the wiring ducts and the

equipment

Do not mount the unit upside down, on a horizontal surface, or

in a vertical arrangement.

Minimum clearance requirement

of 51mm for A, B, and C.

Air

Flow

TX

2

PORT

2

PORT

1

RX

2

RX

1

TX

1

PWR

ER

R

RU

N

ST

OP

RU

N

Air

Flow

TX

2

PORT

2

PORT

1

RX

2

RX

1

TX

1

PWR

ER

R

RU

N

ST

OP

RU

N