O

pe

ra

to

r

P

an

el

Tr

ou

ble

sh

oo

tin

g

6--3

Programming Examples

If you experience communications difficulties between the OP-panel and PLC for a

period of twelve seconds, the LEDs in the corners of the five pushbuttons will flash

rapidly.

In this case, you should check the following items:

1.

Observe the TX and RX LEDs on the rear of the panel. Both LEDs should be a

steady flash or glow (depending on baud rate). If not, check and make sure you

are using the proper communications cable and that it is securely connected.

3.

Examine the communications information for the proper PLC type, protocol,

baud rate, parity, stop bit, address number. Use the user manual for the PLC

product you are using to determine the proper settings.

2.

Examine the PGM/RUN DIP switch to

make sure it is placed in the RUN position.

You must cycle OP-panel power for ad-

dress switch changes to take effect.

4.

If you are using an OP cable, verify cable pinout. For RS--422 connec-

tions use a Belden 9729 or equivalent cable.

5.

Check 24VDC power source and connections.

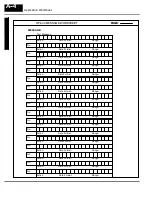

RX/TX LEDs

Rear Panel View

PGM/RUN DIP Switch

Place the PGM/RUN switch in the RUN

position when running the program.

PGM

TERM

RUN

1

2

ON

Direct

LOGIC

PLCs

:

If you are using the secondary communications port such as

Direct

LOGIC PLC port 2, ensure the communications port address and protocol

setting match.

Panel to PLC

Communications

Problems

PLC

Direct

LOGIC