Starting the engine

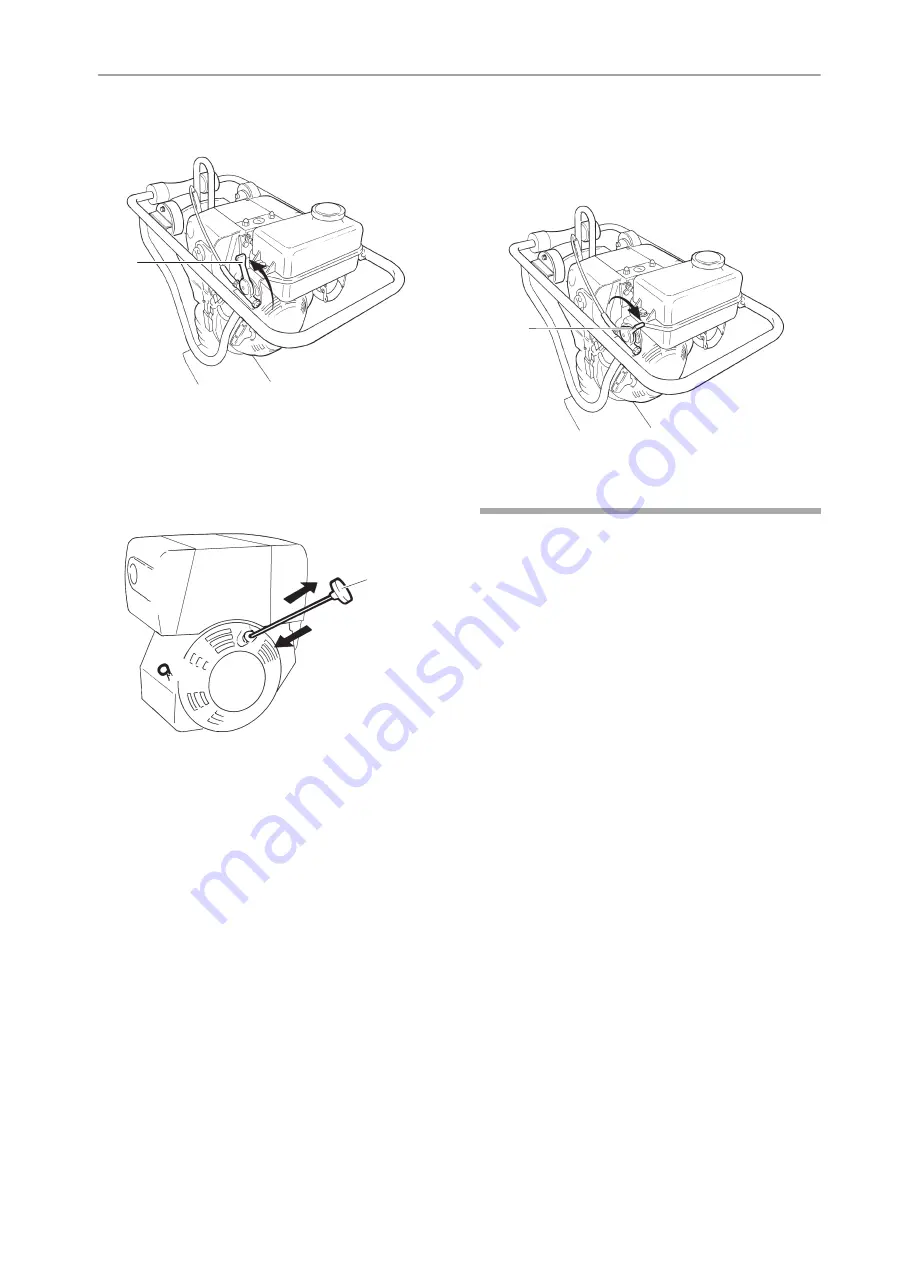

1. Set the throttle control (A) to half revs.

A

2. Pull out the starter rope (B) until resistance is

felt. Release the handle so the starter rope goes

back again, and then pull the starter rope until

the engine starts.

B

3. Set the throttle in idle position and allow the

engine to idle for a few minutes before increasing

to full power.

If the exhaust begins to emit white smoke, after

several attempts of starting, do the following:

1. Move the throttle control to the stop position.

2. Slowly pull the starting cable out 5 times.

3. Repeat the starting procedure.

Stopping the engine

1. Set the throttle control (A) in idle position. Let the

engine run for a few minutes.

2. Set the throttle control (A) in the stop position.

A

Operating

NOTICE

During operation, the engine must always

work at full throttle (working mode).

NOTICE

When operating in narrow trenches, there

is a risk of the rammer leg fastening between the

trench walls. The rammer can then miss-strike and

become damaged. The rammer shoe in particular

could be severely damaged. When operating in

trenches, make sure that they are wide enough

before starting.

♦

Operate the rammer on a level surface.

♦

Never operate on hard surfaces (solid rock,

hardened concrete etc).

♦

Steer the machine with the handle.

♦

Excessive pressure on the handle will result in

poor compaction by obstructing the vibratory

action.

♦

The rammer must not be pressed down into the

material being compacted.

♦

If the machine tips over during operation, switch

off the engine before lifting it up.

15

© 2011 Atlas Copco Construction Tools AB | No. 9800 1139 01 | 2011-04-01

Original instructions

Safety and operating instructions

LT 800