F 31.18 4

1.2

Points of maintenance

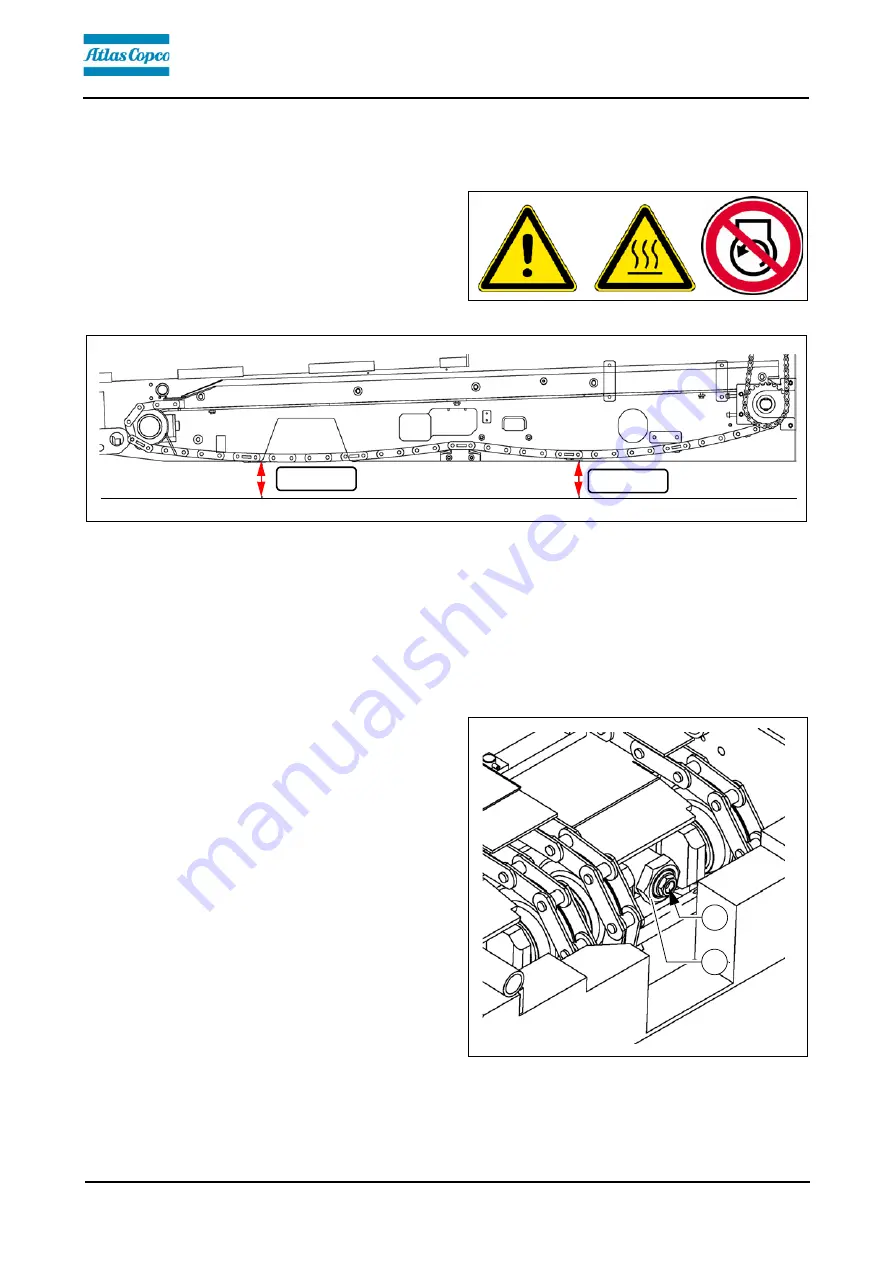

Chain tension, conveyor (1)

Check chain tension:

When the conveyor chain is tensioned correctly, the lower edges of both chain sags

(before and after the chain guide) hangs approx. 170 mm above the ground.

m

The conveyor chains should not be too tight or too slack. An excessively taut chain

can cause the chain to be stopped or to break when material falls into the space be-

tween the chain and the sprocket.

If the chains are too slack, it may get stuck in the protruding objects and be damaged.

Adjustment of chain tension:

A

One adjusting screw is located on both

halves of the conveyor for adjusting the

chain tension.

A

The adjusting screws are located at the

reversal behind the crossbeam.

A

A special wrench for the lock nut (A) is

included in the scope of supply of

the vehicle.

- Unfasten lock nut (A) at the reversal.

- Adjust the chain tension using the ad-

justing screw (B).

- Retighten the lock nut (A) properly.

170 mm

170 mm

B

A

Содержание Dynapac F1800C

Страница 2: ...www atlascopco com...

Страница 10: ...8...

Страница 24: ...A 2...

Страница 32: ...B 8 4 Safety devices 5 7 11 4 5 6 7 3 1 2 9 12 10 10 8...

Страница 42: ...B 18 22 21 22 21 22 21 8 52 4 5 72 6 50 2 1 28 29 30 3 33 32 31 3 20 60 12 25 10 26 9 23 6 11 27 24...

Страница 43: ...B 19 71 70 40 41 42 xxxxxxxxxxxxxxxxx 7 7 51 53...

Страница 78: ...D 10 18 4 10 15 16 19 18 20 17 14 11 12 10...

Страница 80: ...D 10 18 6 10 15 16 19 18 20 17 14 11 12 10...

Страница 82: ...D 10 18 8 10 15 16 19 18 20 17 14 11 12 10...

Страница 84: ...D 10 18 10 24 23...

Страница 86: ...D 10 18 12 26 25...

Страница 88: ...D 10 18 14 28 27 30 29...

Страница 90: ...D 10 18 16 28 27 30 29...

Страница 92: ...D 10 18 18 32 31...

Страница 94: ...D 10 18 20 34 33...

Страница 96: ...D 10 18 22 35...

Страница 98: ...D 10 18 24 37 36...

Страница 100: ...D 10 18 26 38...

Страница 102: ...D 10 18 28 39...

Страница 104: ...D 10 18 30 40...

Страница 106: ...D 10 18 32 41...

Страница 108: ...D 10 18 34 43 42...

Страница 110: ...D 10 18 36 44 45 46 47...

Страница 112: ...D 10 18 38 48 50 51 49...

Страница 114: ...D 10 18 40 48 50 51 49...

Страница 116: ...D 10 18 42 52 53 54 55 56 57...

Страница 118: ...D 10 18 44 60 64 63 65 67 62 61 66 68...

Страница 120: ...D 10 18 46 60 64 63 65 67 62 61 66 68...

Страница 124: ...D 10 18 50 90 91 92 95 94 96 93 97 97...

Страница 126: ...D 10 18 52...

Страница 129: ...D 30 18 3 Control platform telescoping seat consoles 10 B A B 11 6 4 5 2 8 A 9 7 12...

Страница 162: ...D 30 18 36...

Страница 167: ...D 40 18 5 1 3 10 2 8 6 6 4 5 7 9...

Страница 170: ...D 40 18 8 1 3 10 2 8 6 4 5 7 9 6...

Страница 173: ...D 40 18 11 2 3 4 1...

Страница 175: ...D 40 18 13 1 2 3 5 7 6...

Страница 177: ...D 40 18 15 2 2 3 1 6 5 4...

Страница 181: ...D 40 18 19 1 A 3 2 4...

Страница 183: ...D 40 18 21 1 2 5 6 7 4 11 10 3 9 8 12...

Страница 186: ...D 40 18 24 1 2...

Страница 188: ...D 40 18 26 1 3 14 9 2 9 7 6 4 10 12 11 13 5 15 5 8 4...

Страница 190: ...D 40 18 28 2 Malfunctions 2 1 Error code query for engine 3 1 2...

Страница 198: ...D 40 18 36...

Страница 213: ...F 20 18 1 F 20 18 Maintenance review 1 Maintenance review 70 18 40 18 50 18 82 18 90 100 31 18 60 18...

Страница 215: ...F 31 18 1 F 31 18 Maintenance conveyor 1 Maintenance conveyor...

Страница 222: ...F 31 18 8...

Страница 223: ...F 40 18 1 F 40 18Maintenance auger assembly 1 Maintenance auger assembly...

Страница 247: ...F 60 18 1 F 60 18 Maintenance hydraulic system 1 Maintenance hydraulic system...

Страница 262: ...F 60 18 16...

Страница 263: ...F 70 18 1 F 70 18 Maintenance drive units 1 Maintenance drive units...

Страница 275: ...F 82 18 1 F 82 18 Maintenance electrical system 1 Maintenance electrical system...

Страница 290: ...F 82 18 16...

Страница 298: ...F 90 18 8...

Страница 299: ...F 100 1 F 100 Tests stopping 1 Tests checks cleaning stopping...

Страница 308: ...F 100 10...

Страница 310: ...F 110 18 2 2 6 6 1 7 3 4 5...

Страница 316: ...F 110 18 8...

Страница 318: ...www atlascopco com...