Safety label

XXX XX

Co

nst

ruc

tio

n T

oo

ls AB

Atla

s C

op

co

NA

CK

A- SWE

DEN

Desi

gned

b

y

Ordering No

XXXX XXXX XX

Type

Pmax bar(e)

XXX XX

20 (290psi)

FLOW

MAX

MI

N

A

B

C

A.

Machine type

B.

Maximum permitted compressed air pressure

C.

The warning symbol together with the book

symbol means that the user must read the

safety and operating instructions before the

machine is used for the first time.

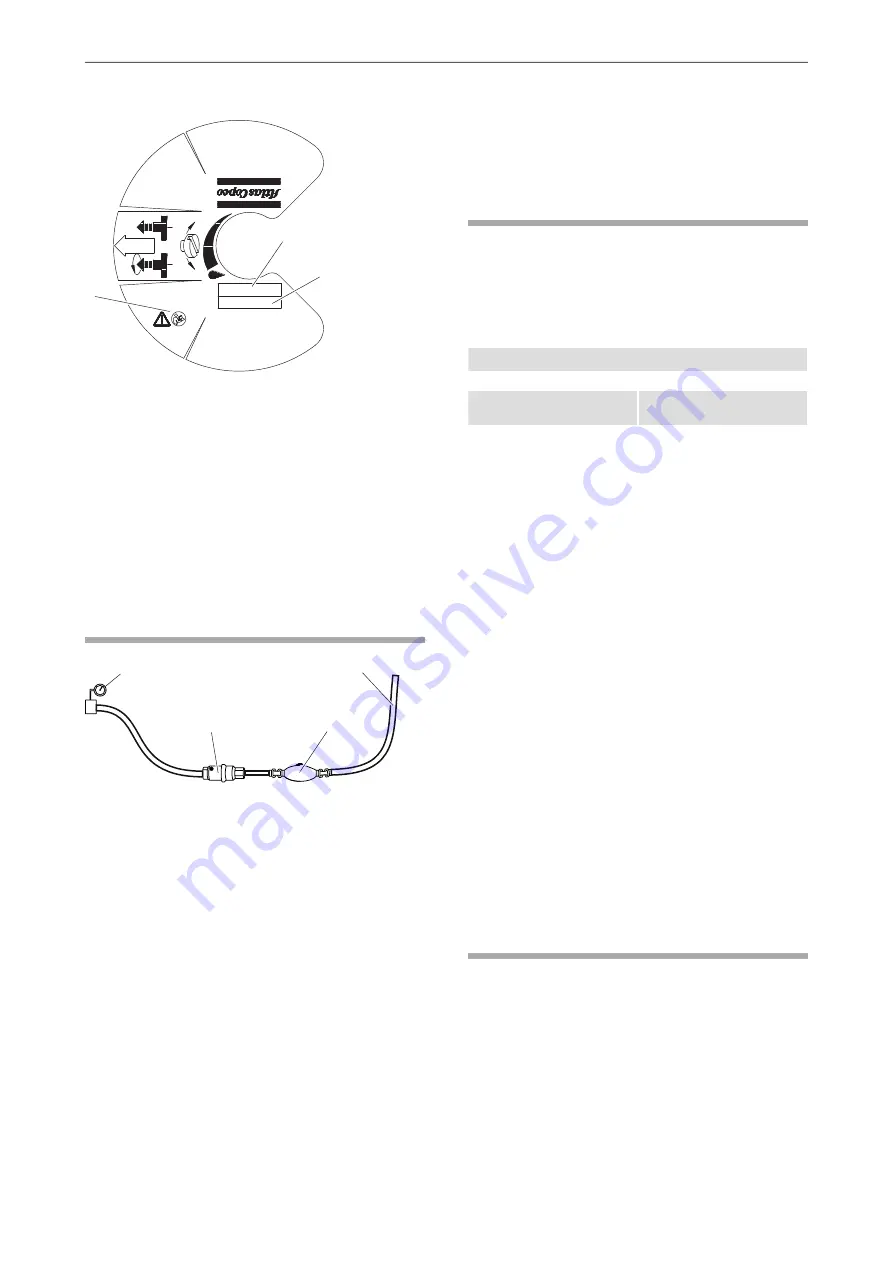

Installation

Hoses and connections

A

B

C

D

A.

Compressed air source

B.

Water separator (optional)

C.

Lubricator

D.

Max. 3 m (10 ft) compressed air hose between

the lubricator and the pneumatic machine.

♦

The maximum permissible air pressure, 20 bar (e)

(290 psi), must not be exceeded.

♦

Blow any impurities out of the compressed air hose

before connecting it to the lubricator.

♦

For the CLG 10 a hose with a minimum internal

diameter of 12.5-16.0 mm (

1

⁄

2

-

5

⁄

8

in.) must be used.

For the CLG 30 a hose with a minimum internal

diameter of 20-25 mm (

3

⁄

4

-1 in.) must be used.

♦

There is a an arrow on the lubricator to indicate

the correct direction of air flow. When connecting

the lubricator, make sure that the arrow points in

the same direction as the air flow.

Lubrication

The lubricant is important for the pneumatic

machine’s function and has a great impact on the

useful service life. To guarantee good lubrication,

the length of the air hose between the lubricator and

the pneumatic machine must not exceed 3 meters.

Viscosity range

Viscosity

Temperature °C (°F)

ISO VG 46–68

200-300 SUS

+15 to +50

(+59 to +122)

ISO VG 22–32

100-150 SUS

-20 to +15

(-4 to +59)

For the correct recommended lubrication oil, refer to

the Safety and operating instruction for the pneumatic

machine used together with the lubricator.

Oil adjustment

CLG 10 and 30 are delivered with the oil dosage

screw in the fully open position. The oil dosage screw

can be turned through a total of four complete turns.

It is steplessly adjustable.

To adjust the oil dosage, do the following:

♦

Use a screwdriver to turn the oil dosage screw.

Clockwise reduces oil flow.

Anticlockwise increases oil flow.

♦

Never remove the spring pin. If the oil dosage

screw become loose, the spring pin will prevent it

from blowing out of the lubricator.

♦

Check the exhaust port of the pneumatic machine

to see that sufficent lubrication is being exhausted.

Operation

Operating

Filling the lubricator with oil

Always top up the lubricator with oil at the start of

the shift.

♦

Switch off the air supply to the lubricator.

♦

Vent the air line, to remove trapped air.

♦

Clean around the outside of the filler plug to

prevent dirt from entering the lubricator.

9

© 2015 Construction Tools PC AB | No. 9800 1172 01a | 2015-04-10

Original instructions

Safety and operating instructions

CLG 10, 10 US, 30, 30 US