General information

T

WARNING

Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

Safety signal words

The safety signal words Danger, Warning, Caution, and Notice have the following meanings:

DANGER indicates a hazardous situation which, if not avoided,

will

result in death

or serious injury.

DANGER

WARNING indicates a hazardous situation which, if not avoided,

could

result in

death or serious injury.

WARNING

CAUTION, used with the safety alert symbol, indicates a hazardous situation which,

if not avoided, could result in minor or moderate injury.

CAUTION

NOTICE is used to address practices not related to personal injury.

NOTICE

Warranty

Contact the Atlas Copco sales representative within your area to claim a product. Warranty will only be approved

if the product has been installed, operated and overhauled according to the Operating Instructions.

Please also see the delivery conditions applied by the local Atlas Copco company.

ServAid

ServAid is a utility for providing updated product information concerning:

- Safety instructions

- Installation, Operation and Service instructions

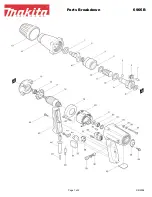

- Exploded views

ServAid facilitates the ordering process of spare parts, service tools and accessories for the product of your

choice. It is continuously updated with information of new and redesigned products.

You can use ServAid to present content in a specific language, provided translations are available, and to

display information about obsolete products. ServAid offers an advanced search functionality of our entire

product range.

ServAid is available on DVD and on the web:

http://servaidweb.atlascopco.com

For further information contact your Atlas Copco sales representative or e-mail us at:

Overview

Applications

This powerful, high-speed impact wrench (LMS) is typically used for loosening applications where fast tight-

ening or disassembly is needed.

Service intervals

Service recommendations

Overhaul and preventive maintenance is recommended at regular intervals. See

the Preventive maintenance

section for detailed information regarding overhaul of your tool and specific parts. If the machine is not working

properly, it should immediately be taken away for inspection. At the overhauls, all parts should be cleaned ac-

curately and defective or worn parts should be replaced.

3

© Atlas Copco Industrial Technique AB - 9836 6500 00

Product information

EN

LMS88 GIR38